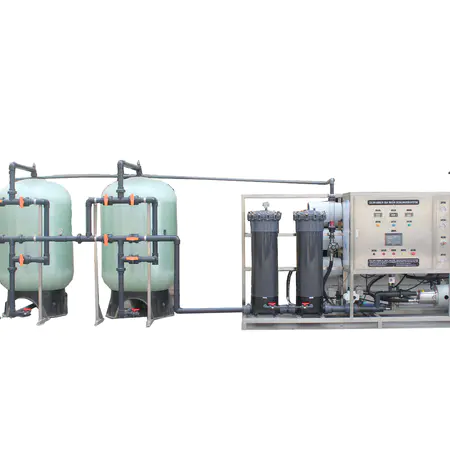

What is membrane housing?

The membrane housing is a filter device made of composite materials. The commonly used membrane housing is mainly used in seawater desalination and sewage treatment. Usually there are glass fiber reinforced plastic membrane housing, stainless steel membrane housing, ceramic membrane housing, and there are many models, according to different functions, the models are also different.

With many years of professional manufacturing experience.

Real factory,real factory direct sales,saving the cost of middlemen,the price is 10%-15%lower than the competitors.

Complete customer files,regular tracking of equipment operation Respond promptly and solve problems reported by customers.

We have a strong production capacity can ensure rapid delivery at the appointed time.

Related Products

More items about membrane housing

membrane housing

Guangdong Stark Water Treatment Technology Co., Ltd. is a company that focuses on watertreatment plant and is committed to the research and development, production, sales and after-sales service of environmentally friendly water purification industrial products.

The main production and operation of water treatment plant: reverse osmosis system, ultrafiltration system, EDI desalination system, sea water desalination plant, brackish water desalination plant. Products are widely used in electronics, electroplating, power plants, medicine, petroleum, chemical, food and beverage, printing and dyeing indutries. Starck strives to be the forefront explorer of water treatment equipment at home and abroad!

Introduction to types of membrane housing

Types of membrane housing: The membrane shells of reverse osmosis and nanofiltration membranes are generally made of FRP or stainless steel because they must withstand greater pressure. Ultrafiltration membrane shells generally use UPVC or ABS, because the working pressure of ultrafiltration is generally relatively low. In addition to membrane shells for water treatment equipment, UPVC pipes can also be used to make small ion exchange beds.

User Reviews

What users say about Stark

The quality of the product is very good, as described by the manufacturer, the speed of logistics and freight is very powerful, and a very satisfactory transaction.

John

The manufacturer is very strong, and it is very easy to cooperate, the delivery speed is very fast, and the quality is guaranteed! Looking forward to the next cooperation!

I have understood each other in all aspects before cooperation. It is indeed a very honest manufacturer. The delivery date is accurate. I hope to have further cooperation next time!

Frequently Asked Question

Do you have any question?

We have 12 production lines, six quality inspection teams, and hundreds of skilled workers who have worked for more than five years. The delay rate in the last years has been less than 0.3%.

Yes sure ,small order are also welcomed.

Stainless steel products are automatically welded and polished.

Get In Touch

Don't hesitate to contact us!

- reverse osmosis system

- stainless steel water tank

- water softener

- membrane housing

- ozone generator

- uv sterilizer

- cartridge filter

- frp tank

- filter tank

- water tank

- sea water desalination

- ro membrane

- ultrafiltration equipment

- uf equipment

- water treatment plant

- water treatment

- ro treatment plant

- water purification machine

- ro water system

- pure water equipment

- reverse osmosis water filter

- uf system

- uf membrane

- water pump

- water purification system

.jpg?imageView2/1/w/450/h/450/format/webp)