4040/8040 유리 섬유 해수 멤브레인 하우징 압력 용기용 FRP 멤브레인 하우징

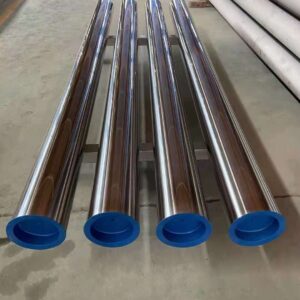

Secure robust and highly corrosion-resistant membrane containment with Stark Water’s FRP Membrane Housing 4040/8040. This fiberglass seawater membrane housing is designed as a high-pressure vessel, precisely engineered to protect 4040 and 8040 RO membranes in demanding seawater desalination and industrial applications.

제품 설명

Seawater desalination and high-purity industrial processes involving aggressive chemistries present some of the most challenging environments for water treatment equipment. The integrity and material quality of membrane housings are paramount for safety, efficiency, and longevity. The Stark Water FRP Membrane Housing 4040/8040 is specifically engineered to excel in these extreme conditions, providing a superior, highly corrosion-resistant solution for containing RO membrane elements under very high pressures.

The Ultimate Corrosion Resistance: Fiberglass Seawater Membrane Housing

The defining feature of this product is its construction from Fiberglass Reinforced Plastic (FRP), specifically designed as a fiberglass seawater membrane housing. FRP offers an unparalleled advantage in environments where stainless steel might eventually succumb to pitting or crevice corrosion due to high chloride concentrations. This makes our FRP membrane housing the material of choice for:

- Seawater Desalination: Impervious to the highly corrosive effects of concentrated brine and seawater.

- Aggressive Chemical Environments: Resists a broad spectrum of acids, bases, and oxidizing agents often present in industrial processes or used for membrane cleaning.

- Long-Term Durability: Provides exceptional longevity and structural integrity without rusting or degrading over time, even under continuous exposure to harsh conditions.

This inherent material superiority ensures that the membrane housing maintains its performance and safety characteristics throughout its extended operational lifespan, making it a truly reliable choice for critical applications.

High-Pressure Vessel for 4040/8040 RO Membranes

Our FRP Membrane Housing is designed as a robust high-pressure vessel, capable of safely withstanding the extreme internal pressures (often 800-1200 PSI) required for efficient seawater reverse osmosis (SWRO) and high-recovery brackish water RO systems. It is available with precise internal dimensions to accommodate both standard 4040 RO membrane elements (4-inch diameter, 40-inch length) and 8040 RO membrane elements (8-inch diameter, 40-inch length). This dual compatibility offers immense flexibility for system designers, allowing for efficient scaling of purification capacity while utilizing a trusted housing type. The meticulous design ensures a leak-proof seal and optimal membrane seating, preventing bypass and maximizing the efficiency of the purification process.

Reliability, Safety, and Optimized Performance in Demanding Applications

The Stark Water Fiberglass Seawater Membrane Housing is built for unyielding reliability and safety. Its robust construction and adherence to pressure vessel standards ensure integrity under demanding operating conditions. By providing a secure and stable environment for the RO membranes, it contributes directly to achieving optimal permeate flow and contaminant rejection, thereby extending the lifespan of valuable membranes and safeguarding the purity of the treated water. This combination of material superiority, high-pressure capability, and versatile sizing makes it an indispensable component for any large-scale seawater desalination or high-purity industrial application.

제품 매개변수

The STARK FRP Membrane Housing 4040/8040 is engineered for robust, high-pressure performance in demanding seawater and industrial applications. Here are its key technical specifications:

| 매개변수 | 사양 / 사용자 지정 옵션 |

|---|---|

| 핵심 키워드 포커스 | FRP Membrane Housing design and capabilities. |

| 호환되는 멤브레인 크기 | 4040(직경 4인치 x 길이 40인치) 및 8040(직경 8인치 x 길이 40인치) RO 멤브레인 엘리먼트. 크기에 따라 용기당 1개에서 7개 이상의 요소를 사용할 수 있습니다. |

| 재료 구성 | Fiberglass Reinforced Plastic (FRP) with high-quality liner (e.g., Polyethylene, Polypropylene, or Epoxy Vinyl Ester) chosen for specific chemical resistance. |

| Maximum Operating Pressure | Designed as a High Pressure Vessel: Typically 600 PSI, 1000 PSI, or 1200 PSI (4.1 MPa – 8.3 MPa), specifically for Seawater RO (SWRO) or high-pressure BWRO. |

| 디자인 유형 | 엔드-입력 또는 사이드-입력 포트. 다중 포트 옵션(예: 8040용 2.5인치, 4인치 측면 포트). |

| 포트 연결 | Threaded (NPT/BSP) or Flanged connections, designed for high pressure. |

| 엔드 캡 유형 | Quick-Lock (clamped) or Bolt-on for secure closure and easy membrane replacement. |

| 씰링 재료 | 온도 및 화학적 호환성에 따라 선택되는 EPDM, Viton(FKM) 또는 Buna-N(NBR) O링입니다. |

| 외부 마감 | Standard gel coat (various colors available) or painted. |

| Maximum Operating Temperature | Up to 49°C (120°F) for standard seals and materials; higher with specialized materials. |

| 마운팅 하드웨어 | 스테인리스 스틸 마운팅 안장과 스트랩이 포함되어 있습니다. |

| 테스트 및 인증 | Hydrostatic pressure tested; designed to relevant industry standards (e.g., ASME, PED) for pressure vessels. |

| Corrosion Resistance | Excellent resistance to highly corrosive media, including seawater, brines, acids, and bases. |

해당 산업

The STARK FRP Membrane Housing 4040/8040, as a robust fiberglass seawater membrane housing, is a critical and adaptable component for high-pressure RO systems across a diverse range of demanding industrial and municipal sectors. Its superior corrosion resistance and high-pressure capability make it indispensable for:

- Seawater Desalination Plants: Essential for containing SWRO membranes under extremely high pressures, enabling the efficient conversion of highly saline seawater into fresh, potable, or process water for coastal communities, industries, and island nations.

- Brackish Water Reverse Osmosis Systems (High TDS/Corrosive): For purifying challenging brackish groundwater with higher salt content or corrosive properties, where conventional materials might degrade.

- Industrial Wastewater Treatment & Reuse (Challenging Effluents): Applied in RO stages of advanced industrial wastewater treatment plants to produce high-quality effluent, especially when dealing with corrosive or high-TDS industrial discharges.

- Power Generation (SWRO Pre-treatment): Critical for containing RO membranes in systems providing boiler feed water or cooling tower make-up water from seawater sources.

- Chemical Processing: For RO systems purifying water for chemical formulations, or treating process streams where the FRP’s chemical resistance is a distinct advantage against specific chemicals.

- Oil & Gas Industry: Used in systems for produced water treatment or offshore RO applications where robust, corrosion-resistant components are vital due to the harsh operating environment and fluid characteristics.

- Mining & Metallurgy (Process Water): For treating highly mineralized or corrosive process water using RO, benefiting from the housing’s material properties.

- Pharmaceutical & Medical Industry (Specific Use): For RO systems used in utility applications where specific corrosive agents might be present in the feed or cleaning solutions, requiring robust containment.

장점 1

이점 2

관련 제품

연관 상품

자주 묻는 질문

Q1: 역삼투압 시스템의 수명은 얼마나 되나요?

역삼투압 시스템의 수명은 수질과 유지 관리에 따라 달라집니다. 일반적으로 멤브레인의 수명은 2~3년이며, 시스템 자체는 적절한 관리를 통해 10년 이상 지속될 수 있습니다.

Q2: 다양한 수질 조건에 따라 시스템을 맞춤 설정할 수 있나요?

예, 모든 시스템은 완벽하게 사용자 정의할 수 있습니다. 고객의 수질 보고서와 애플리케이션 요구 사항을 분석하여 맞춤형 솔루션을 제공합니다.

Q3: STARK 장비는 어떤 표준을 준수하나요?

당사의 제품은 CE, ISO 9001을 준수하며 요청에 따라 특정 지역 규정 또는 산업 표준을 충족하도록 설계할 수 있습니다.

Q4: STARK RO 시스템의 배송 시간은 어떻게 되나요?

표준 시스템은 7~15일 이내에 배송됩니다. 맞춤형 주문의 경우 복잡성에 따라 리드 타임이 20~25일로 연장될 수 있습니다.

Q5: 기술 지원이나 설치 안내를 제공하나요?

예. 전체 기술 문서와 비디오를 통한 원격 지원을 제공하며, 요청 시 엔지니어를 해외로 파견할 수 있습니다.

Q6: 견적에는 무엇이 포함되나요?

견적에는 전체 RO 시스템, 제어판, 펌프, 전처리 장치 및 필요한 모든 피팅이 포함됩니다. 요청 시 설치 도구와 예비 부품도 포함될 수 있습니다.