STARK 대형 역삼 투 필터 시스템 담수화 정화 처리 플랜트 판매 로 기계 가격

STARK 대형 역삼 투 필터 시스템 담수화 정화 처리 플랜트 판매 로 기계 가격STARK 대형 역삼 투 필터 시스템 담수화 정화 처리 플랜트 판매 로 기계 가격

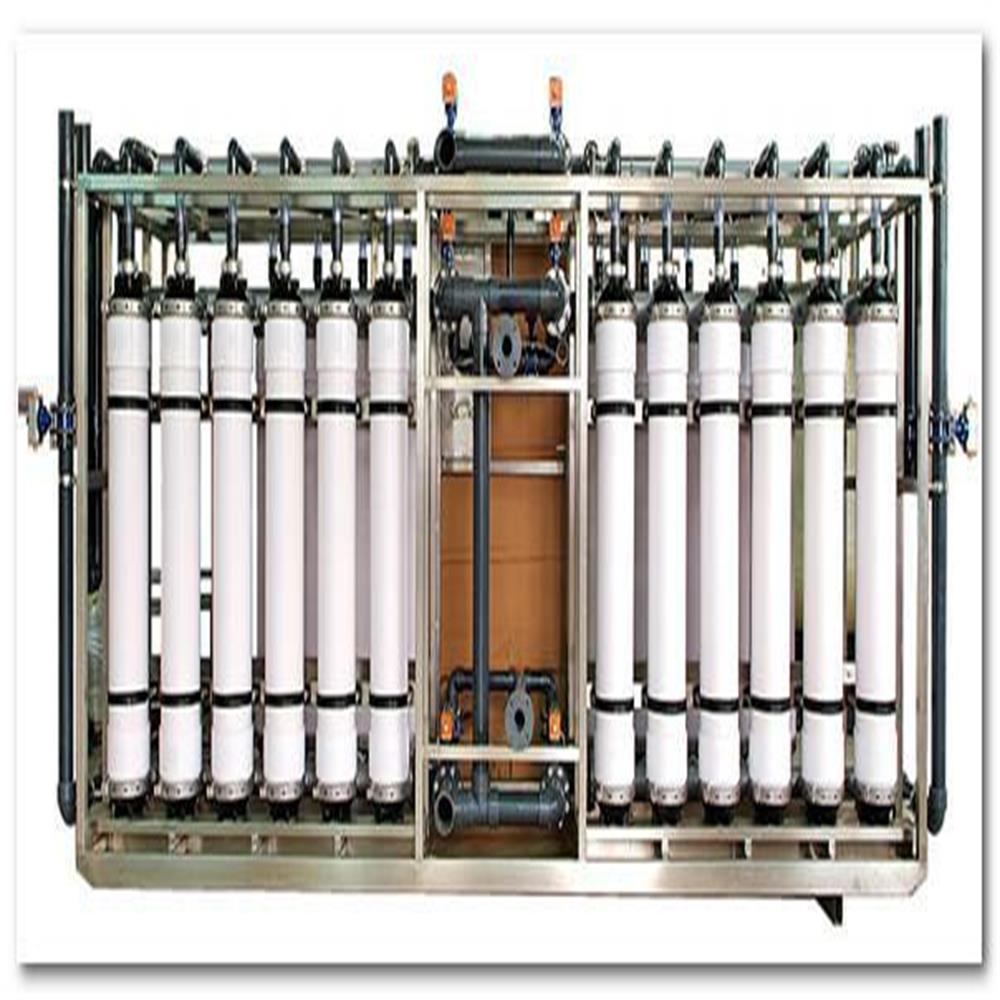

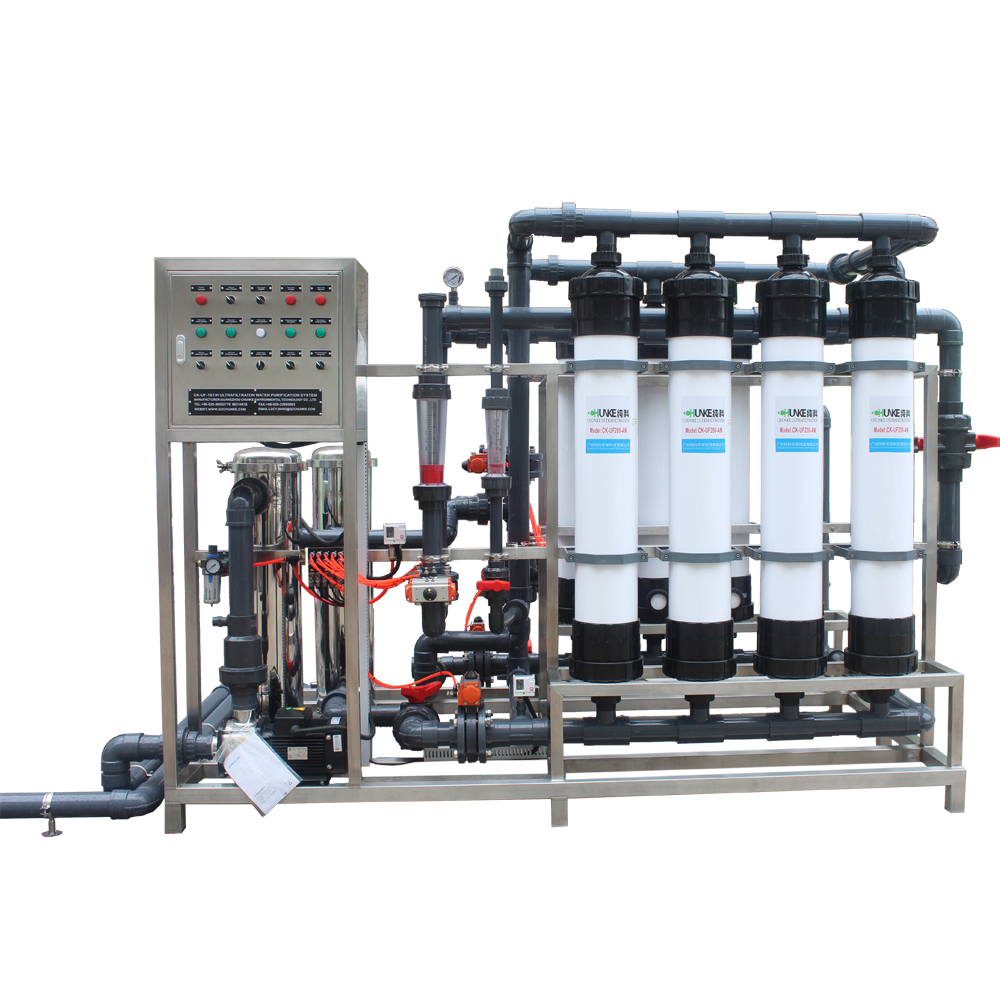

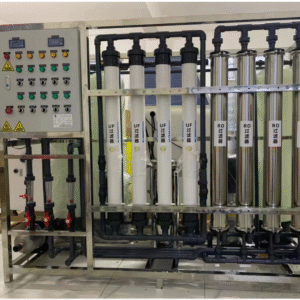

Elevate your water supply with Stark Water’s Big Reverse Osmosis Filter System. This powerful reverse osmosis filter system is a comprehensive desalination and purification treatment plant, designed for large-scale industrial and municipal needs. Delivering exceptional water quality and efficiency, it’s a top-tier RO machine available at a competitive price.

제품 설명

For large-scale industrial operations, municipalities, and communities facing critical water scarcity or quality challenges, a robust and highly efficient purification solution is essential. The Stark Water Big Reverse Osmosis Filter System is engineered to meet these immense demands, providing a comprehensive and reliable answer for desalination, purification, and overall water treatment. This state-of-the-art reverse osmosis filter system is a strategic investment in securing a sustainable and high-quality water supply.

Large-Scale Desalination and Purification Capabilities

Our Big Reverse Osmosis Filter System is designed for substantial capacity, making it suitable for major industrial needs or serving large populations. It excels as a complete desalination purification treatment plant, capable of transforming highly saline water sources, including seawater and brackish groundwater, into fresh, potable water. Utilizing advanced thin-film composite (TFC) membranes and high-pressure pumping technology, it achieves exceptional contaminant rejection rates, effectively removing up to 99.7% of dissolved salts, minerals, heavy metals, organic compounds, bacteria, and viruses. This comprehensive purification ensures that the treated water consistently meets the most stringent international standards for drinking water or industrial process requirements.

A Complete RO Machine for Sale

This system is presented as a complete RO machine for sale, encompassing all necessary stages for effective purification. It typically includes:

- Advanced Pre-treatment: Multi-media filters (sand, activated carbon), water softeners (if needed), and micron cartridge filters to protect the delicate RO membranes from fouling and extend their lifespan.

- High-Pressure RO Module: Robust membrane pressure vessels housing high-rejection RO membranes, driven by energy-efficient, high-pressure pumps.

- Post-treatment (Optional but Recommended): Depending on desired final water quality, options like UV sterilization for microbiological control, chemical dosing for pH adjustment or disinfection, and advanced deionization (EDI) for ultra-pure water production can be integrated.

- Sophisticated Control System: Fully automated PLC control with Human Machine Interface (HMI) for real-time monitoring of critical parameters, automatic cleaning cycles (CIP), alarm functions, and remote access capabilities for optimal operational management.

The integrated design ensures seamless operation and maximum efficiency, simplifying management of complex large-scale water treatment processes.

Optimized Efficiency and Competitive Price

Investing in the Stark Water Big Reverse Osmosis Filter System is a commitment to long-term efficiency and value. We strive to offer a competitive price for this high-capacity **RO machine**, making advanced water treatment accessible for large-scale projects. The system’s high water recovery rates, coupled with energy-efficient components, translate into lower operational costs and reduced raw water consumption. Furthermore, the robust construction and automated operation minimize maintenance needs and downtime, ensuring a highly reliable and cost-effective solution for securing your purified water supply. It’s an investment that pays dividends through sustainable operations and consistent water quality.

제품 매개변수

| 매개변수 | 사양 / 사용자 지정 옵션 |

|---|---|

| 핵심 키워드 포커스 | Reverse osmosis filter system 디자인 및 성능. |

| 순수한 물 용량 | Customizable, typically ranging from 50 m³/hr to 500+ m³/hr (or higher for very large projects). Specified per client requirements. |

| 원수 공급원 호환성 | Highly versatile for Municipal Water, Well Water, Brackish Water (TDS up to 15,000 ppm), or Seawater (TDS up to 45,000 ppm for SWRO configuration). |

| RO Membrane Type | High-rejection, low-fouling Thin-Film Composite (TFC) RO Membranes (e.g., 8040 series, quantity scaled for capacity/TDS). Specialized SWRO membranes for desalination. |

| High-Pressure Pump | Heavy-duty, high-efficiency, corrosion-resistant centrifugal or positive displacement pumps, often with Variable Frequency Drives (VFDs) for optimized energy use. |

| Pre-treatment System |

|

| Salt Rejection Rate | ≥98.5% – 99.5% (BWRO); ≥99.5% – 99.7% (SWRO) |

| Water Recovery Rate | 40% – 75% (BWRO); 30% – 50% (SWRO) – Dependent on raw water quality, desired recovery, and system design. |

| 출력 수질 | Meets WHO drinking water standards; customized for specific industrial process water needs (e.g., low TDS for boiler feed, ultra-pure water for electronics post-EDI). |

| 전원 공급 장치 | 3상, 380V/415V/460V, 50Hz/60Hz(지역 표준에 따라 사용자 지정 가능). |

| 제어 시스템 | Advanced Fully Automatic PLC Control with HMI (Human Machine Interface), real-time online monitoring of all critical parameters (TDS/conductivity, pressure, flow, temperature), auto-flush, CIP (Clean-in-Place), and comprehensive safety interlocks/alarms. Remote monitoring capability. |

| 건축 자재 |

|

| 유입수 요구 사항 |

|

| 치수(대략적인) | Large industrial footprint; fully customized based on capacity and configuration. |

| 작동 온도 | 5°C - 45°C. |

| 인증 | 관련 국제 표준(예: ISO, CE, ASME, 요청 시)을 충족하도록 설계되었습니다. |

해당 산업

- Municipal Water Utilities: Provides immense volumes of safe, potable drinking water for large cities, regions, or communities, especially vital in areas facing severe freshwater scarcity through large-scale desalination projects.

- Large Industrial Parks & Manufacturing Facilities: Supplies high-purity process water for diverse manufacturing operations, including electronics, automotive, textiles, and heavy industries, ensuring product consistency, preventing equipment damage, and meeting stringent quality standards.

- Major Food & Beverage Production Plants: Essential for producing vast quantities of purified water for beverage formulation (bottled water, soft drinks, breweries, dairies), food ingredient processing, and comprehensive cleaning-in-place (CIP) systems, guaranteeing product safety and quality.

- Power Generation & Energy Sector: Critical for boiler feed water purification in thermal and nuclear power plants, cooling tower make-up water, and turbine washing, preventing scaling, corrosion, and improving energy efficiency of high-pressure equipment.

- Pharmaceutical & Biotechnology Giants: Used as the foundational purification stage to generate Purified Water (PW) and pre-treat for Water for Injection (WFI) for drug manufacturing, large-scale bioreactors, and sterile environments, adhering to the strictest GMP standards.

- Mining & Metals Industry: For large-volume process water, mineral extraction, and treatment of challenging water sources (e.g., acid mine drainage), contributing to operational efficiency and environmental compliance.

- Oil & Gas Industry: Provides treated water for injection in oil recovery, fracking operations, and various process applications, often requiring large volumes and robust treatment.

- Chemical Water Treatment Plants (Core Component): Serves as the primary purification unit in comprehensive chemical water treatment plants, providing vast quantities of high-purity water for complex chemical formulations, dilutions, and reducing the chemical load on subsequent treatment steps.

- Wastewater Treatment & Reuse (Advanced Systems): Employed in advanced wastewater treatment facilities to produce high-quality effluent suitable for industrial reuse, agricultural irrigation, or even indirect potable reuse, promoting water conservation.

장점 1

이점 2

관련 제품

연관 상품

자주 묻는 질문

Q1: 역삼투압 시스템의 수명은 얼마나 되나요?

역삼투압 시스템의 수명은 수질과 유지 관리에 따라 달라집니다. 일반적으로 멤브레인의 수명은 2~3년이며, 시스템 자체는 적절한 관리를 통해 10년 이상 지속될 수 있습니다.

Q2: 다양한 수질 조건에 따라 시스템을 맞춤 설정할 수 있나요?

예, 모든 시스템은 완벽하게 사용자 정의할 수 있습니다. 고객의 수질 보고서와 애플리케이션 요구 사항을 분석하여 맞춤형 솔루션을 제공합니다.

Q3: STARK 장비는 어떤 표준을 준수하나요?

당사의 제품은 CE, ISO 9001을 준수하며 요청에 따라 특정 지역 규정 또는 산업 표준을 충족하도록 설계할 수 있습니다.

Q4: STARK RO 시스템의 배송 시간은 어떻게 되나요?

표준 시스템은 7~15일 이내에 배송됩니다. 맞춤형 주문의 경우 복잡성에 따라 리드 타임이 20~25일로 연장될 수 있습니다.

Q5: 기술 지원이나 설치 안내를 제공하나요?

예. 전체 기술 문서와 비디오를 통한 원격 지원을 제공하며, 요청 시 엔지니어를 해외로 파견할 수 있습니다.

Q6: 견적에는 무엇이 포함되나요?

견적에는 전체 RO 시스템, 제어판, 펌프, 전처리 장치 및 필요한 모든 피팅이 포함됩니다. 요청 시 설치 도구와 예비 부품도 포함될 수 있습니다.