Flexible Water Purification Starts with the Right Supply Partner

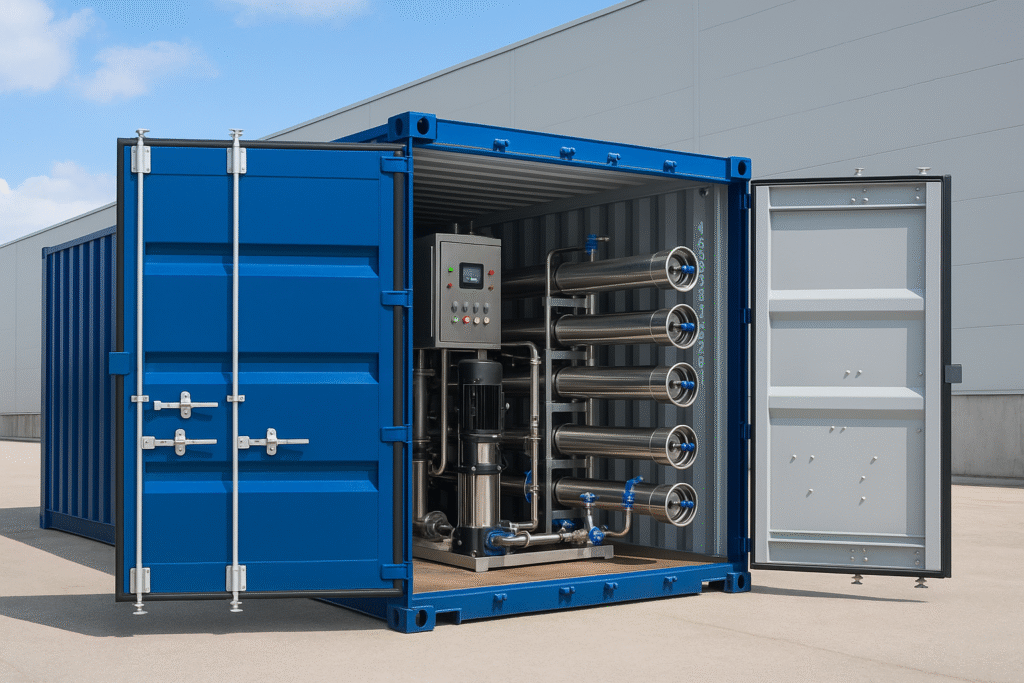

In today’s fast-paced industrial environment, businesses are under growing pressure to secure clean, reliable water supplies—often in challenging locations or under tight timelines. Traditional on-site reverse osmosis (RO) installations can be complex, time-consuming, and infrastructure-intensive. That’s where RO-systemen in container offer a breakthrough: modular, pre-engineered, and easy to deploy.

As a trusted global supplier, STERK Water provides end-to-end support for customers seeking to supply containerized RO system solutions—delivering fully integrated water treatment plants housed in standard 20ft or 40ft containers. This article explores how our containerized systems meet the needs of industries requiring mobility, speed, and performance in water purification.

What Makes a Containerized RO System the Smart Choice for Industrial Projects?

A containerized RO system is a fully self-contained reverse osmosis water purification unit, pre-assembled inside an ISO-standard shipping container. It integrates all key process components—pretreatment, high-pressure pumping, RO membranes, electrical controls, and safety mechanisms—within a weatherproof, transportable structure.

These systems are especially valuable for industries operating in remote locations, tight spaces, or needing fast project turnaround. Unlike traditional RO installations, containerized systems are factory-tested, plug-and-play, and deployable in days rather than months. At STARK, we go a step further by offering dual-stage en chemical-resistant designs for high-demand applications.

- Compact voetstuk: Fits into 20ft or 40ft container formats—ideal for mobile or offshore projects.

- Rapid Deployment: Delivered pre-tested and ready for on-site utility connection.

- Custom Engineering: Configurable for seawater, brackish water, or industrial wastewater inputs.

- Fully Automated: PLC-controlled with options for remote monitoring and digital alerts.

- Minimal Civil Work: No permanent foundation or building required.

For compact water treatment needs, the STARK 20ft Containerized RO System is engineered to support mobile projects, field operations, and decentralized water plants with high reliability.

For high-capacity operations, the 40ft Containerized RO System delivers scalable performance, suitable for export projects, municipal upgrades, and industrial parks.

Where Does a Containerized RO System Make the Biggest Difference?

The value of a containerized RO system lies in its adaptability across a wide range of industries and site conditions. Whether deployed in a manufacturing plant, a mining camp, a construction site, or a coastal desalination project, these systems provide reliable, high-quality water treatment with minimal infrastructure investment.

Below are key sectors where STARK’s containerized RO systems are already making measurable impact:

- Construction & Infrastructure: Supplying water for concrete batching, dust control, and worker camps—especially in temporary job sites where water access is limited.

- Stroomopwekking: Providing high-purity feed water for boilers, turbines, and cooling towers—especially for distributed energy plants in remote areas.

- Food & Beverage: Delivering consistent product-quality water in compliance with hygiene standards—even in export-focused facilities.

- Municipal & Utility: Rapidly expanding treatment capacity during seasonal peak demand or infrastructure upgrades.

- Oil & Gas: Pre-treating water for injection and process needs under harsh, chemically aggressive conditions.

For projects involving complex raw water sources or requiring multi-step filtration, the Dual-Stage Containerized RO System provides layered membrane separation and higher rejection rates—ideal for industrial reuse and brackish water applications.

When chemical resistance is critical, such as in heavy industrial zones or chemical processing plants, our Containerized Chemical Water RO System is engineered with corrosion-resistant materials and enhanced membrane compatibility.

Global Supply Meets Engineering Excellence: Why STARK Is Your Trusted Partner

When it comes to industrial-scale water treatment, sourcing the right containerized RO system supply is about more than just hardware—it’s about long-term performance, technical reliability, and responsive service. At STARK, we combine robust product engineering with global project delivery capabilities to serve clients in over 40 countries.

Here’s what sets us apart as a supplier:

- Factory-Built Systems, Ready for Export: All units are pre-assembled, pressure-tested, and performance-verified before shipment.

- Flexible Customization: Every container can be configured to meet your specific water quality, flow rate, and utility connection requirements.

- Rapid Manufacturing Timelines: With a standardized production model, typical delivery ranges from 2–6 weeks depending on configuration.

- Technical Documentation & Training: We provide comprehensive drawings, wiring diagrams, and O&M manuals, with optional on-site or remote commissioning support.

- Global Logistics Support: From port handling to customs paperwork, our team ensures smooth delivery and deployment to your facility.

Whether you need a single unit for a local project or multiple containerized systems for a global rollout, our supply chain is built for scalability, compliance, and efficiency. We understand the language of project timelines, plant layouts, and water quality specs—because we build systems for engineers, by engineers.

Need help selecting the right containerized RO solution for your project? Contact STARK today for a technical consultation, lead time estimate, and customized proposal.

Unlock Water Treatment Agility with STARK’s Containerized RO Systems

From industrial expansion zones to disaster relief sites, modern businesses require water treatment systems that are fast to deploy, easy to operate, and built to last. Containerized RO systems from STARK deliver exactly that—proven performance, pre-engineered reliability, and global-ready configurations.

As your trusted supply partner, we don’t just deliver containers—we deliver complete water purification solutions tailored to your technical and operational realities.

Key benefits at a glance:

- Rapid deployment (2–6 weeks typical delivery)

- Modular 20ft and 40ft options for any scale

- Dual-stage, chemical-tolerant, and mobile-ready configurations

- Built for RO, brackish, seawater, and custom treatment goals

- Full documentation, testing, and remote/onsite commissioning support

Don’t let limited infrastructure, long installation timelines, or uncertain feedwater conditions delay your operations. Instead, choose a fully supported containerized RO system supply from a company that speaks your industry’s language.

Explore our Dual-Stage Systems | 40ft Industrial Solutions | Compact 20ft Models | Chemical-Resistant Systems

Contact STARK today to discuss your project and receive a tailored solution proposal.