Reading time: 10–14 minutes · Audience: EDI/RO engineers, UPW designers, EPCs

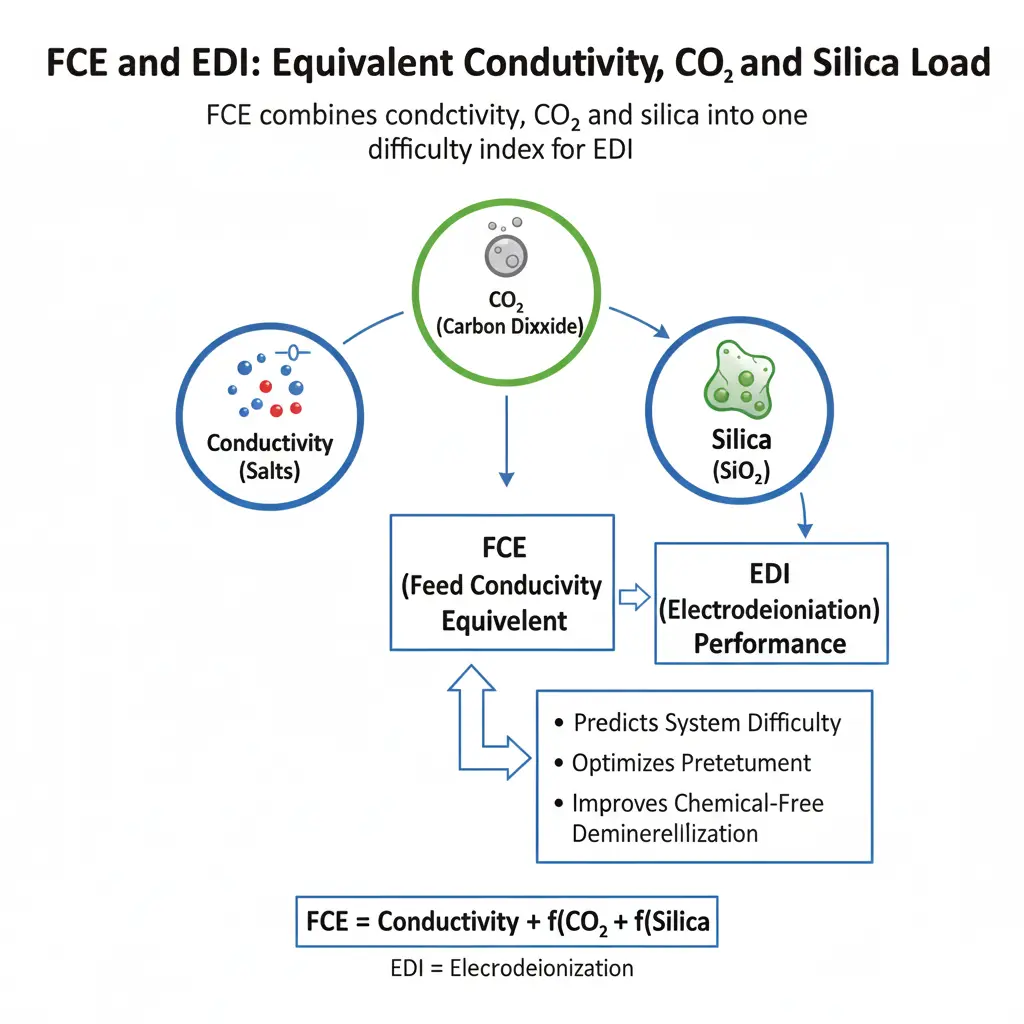

FCE EDI tells you how hard your electrodeionization stack will run by rolling conductivity, CO₂ and silica into one load number.

Executive summary: FCE EDI is the fastest way to predict how difficult your electrodeionization stack will be to run. FCE converts the combined effect of conductivity, dissolved carbon dioxide and silica into a single “load” number. As FCE rises, current efficiency falls, product resistivity drops, and the stack runs hotter.

What Is FCE and Why It Matters

FCE EDI — Definition and Field Use

Engineers use FCE EDI to bridge the gap between meter readings and real stack difficulty. It reflects hidden load from dissolved CO₂ and silica that conductivity alone misses.

FCE (Equivalent Conductivity) is a composite index that converts conductivity + total CO₂ + silica into one figure-of-merit for EDI load. It closes the gap between what a conductivity meter displays and what the EDI stack actually “feels.”

Engineer’s field formula

FCE (µS/cm) = Conductivity (µS/cm) + 2.79 × Total CO₂ (ppm) + 1.94 × SiO₂ (ppm).

- Total CO₂ means CO₂ + HCO₃⁻ + CO₃²⁻ (pH shifts speciation but not the total).

- Worked example: Conductivity 5 µS/cm, Total CO₂ 6 ppm, SiO₂ 1 ppm → FCE = 5 + 2.79×6 + 1.94×1 = 23.7 µS/cm. Planning for “5 µS/cm” would badly underestimate the real EDI burden.

Why CO₂ dominates: CO₂ passes RO while alkalinity largely does not. The carbonate buffer in permeate shifts acidic until degassed, and CO₂/HCO₃⁻ are weakly held on resins—so EDI must remove them or struggle.

How FCE Predicts EDI Product Water

- Higher FCE → higher EDI load: more stack voltage for the same flow and lower product resistivity.

- Conductivity-only specifications underestimate difficulty whenever CO₂ and/or silica are significant.

When teams compare options, the FCE EDI value quickly shows why two feeds with the same conductivity behave differently: one may carry high CO₂ or silica. Designing to the FCE EDI band prevents under-sizing, reduces stack stress, and stabilizes product quality.

Target Windows by Pretreatment Route

| Voorbehandeling | Typical FCE at EDI Inlet | Opmerkingen |

|---|---|---|

| Two-pass RO (RO-RO) | 1–5 µS/cm | Mild NaOH trim ahead of pass-2 converts CO₂→HCO₃⁻ for higher RO rejection; common for UPW (power/semiconductor). |

| RO + Membrane Degasser (GTM/MDG) | 5–15 µS/cm | Best with inlet pH ≤ 6.1 to enhance CO₂ stripping; useful where feed allows. |

| Single-pass RO | 10–30 µS/cm | Meets many industrial/pharma PW needs; CO₂ often limits performance. |

How to Reduce FCE (Action Playbook)

- Improve RO desalting: upgrade membranes; optimize recovery/temperature; stabilize feed pH.

- pH strategy before pass-2: light NaOH to push CO₂→HCO₃⁻ and reject in RO; watch silica ceilings.

- Membrane degassing (GTM): strip dissolved CO₂; run with degasser-inlet pH ~6.0–6.1 for best mass transfer.

- Silica management: respect monomer/polymer limits and pair with RO settings so FCE targets are achievable.

Measurement & Calculation — Getting Reliable FCE

- Where to sample: stabilized RO permeate and EDI feed. Log conductivity (µS/cm), total CO₂ (ppm) and silica (ppm).

- Spreadsheet tip: flag FCE bands with conditional formatting: <5 (green), 5–15 (amber), >15 (red).

- Why pH is not in the formula: pH shifts carbonate speciation but not total CO₂; the total is what loads EDI.

Using FCE in EDI Design & Operations

- Design: choose stack area/current density based on your FCE band; provide degas capacity if band >10 µS/cm.

- Acceptance criteria: tie product resistivity/TOC and stack ΔV/ΔI trends to FCE.

- Troubleshooting linkage: if salts are steady but product worsens, suspect CO₂ breakthrough, degasser performance or air ingress upstream.

FAQ — Quick Answers That Rank

Is FCE just conductivity?

No. It includes weighted contributions from total CO₂ en silica, which often dominate the EDI burden even when conductivity is low.

What FCE should I target for ultrapure water?

For UPW via two-pass RO feeding EDI, aim for FCE 1–5 µS/cm at the EDI inlet.

Why does RO permeate pH usually drop?

CO₂ passes through RO while alkalinity largely does not. The carbonate buffer shifts acidic until degassed.

Further Reading

Next Steps

Want us to map your RO/EDI pretreatment to an FCE target band and ROI? Een offerte aanvragen.