Last updated: November 4, 2025 · Reading time: 12–15 minutes · Audience: landfill operators, EPCs, industrial parks

Landfill leachate treatment is challenging: high ammonium, high COD, high salinity, complex organics, and large seasonal fluctuations. This practical guide compares mainstream routes (MBR+RO, DTRO, A/O + Advanced Oxidation + BAF, evaporation/MVR), shows how to select a compliant process, and sets expectations for O&M and lifecycle cost.

What Is Landfill Leachate?

Landfill leachate forms from moisture in waste, infiltration (rain/groundwater), and biodegradation water. Typical characteristics include high NH4+-N, high COD, elevated TDS/salinity, heavy metals, color, odor, and toxicity. Water quality evolves with landfill age—“young” leachate is more biodegradable with higher COD and ammonia; “old” leachate often shows higher salinity and refractory organics.

For context, see the U.S. EPA landfill guidance and the European Environment Agency resources on waste management and leachate risks.

Compliance & Risk at a Glance

- Stricter limits: many jurisdictions lower TN/NH4+-N and COD, plus color and conductivity caps.

- Continuous monitoring: online analyzers (NH4+-N, NO3–-N, TN, DO, ORP, EC, turbidity) and data logging are increasingly required.

- Documentatie: commissioning SOPs, calibration records, chemical safety sheets, and sludge/concentrate manifests must be complete and traceable.

Opmerking: Always align with local standards and permit. Our engineering team can map your limits to a guaranteed landfill leachate treatment train.

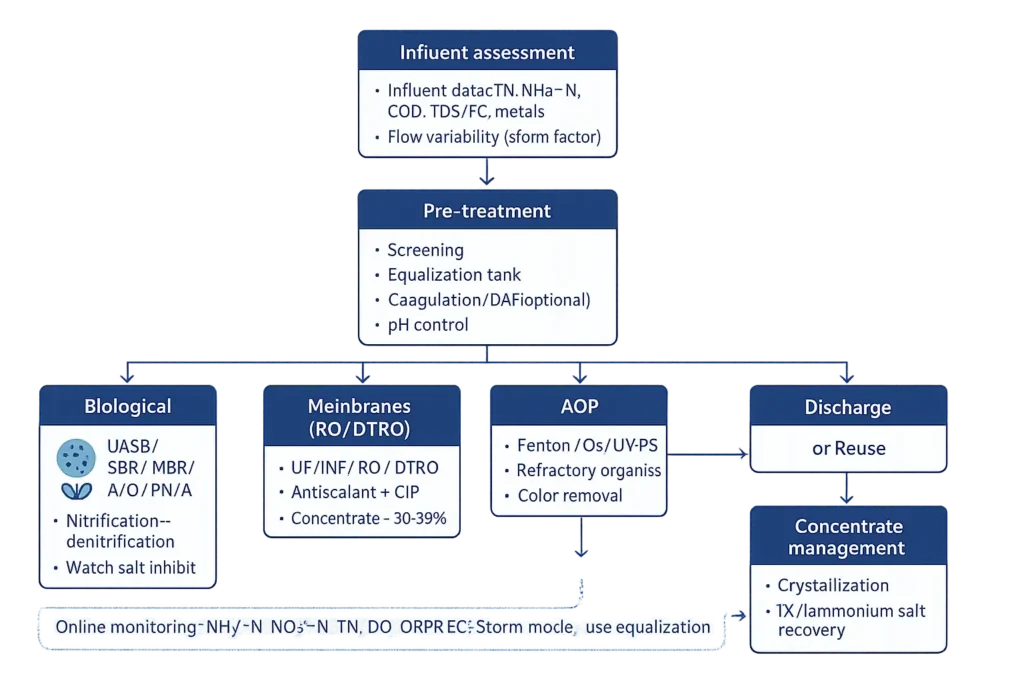

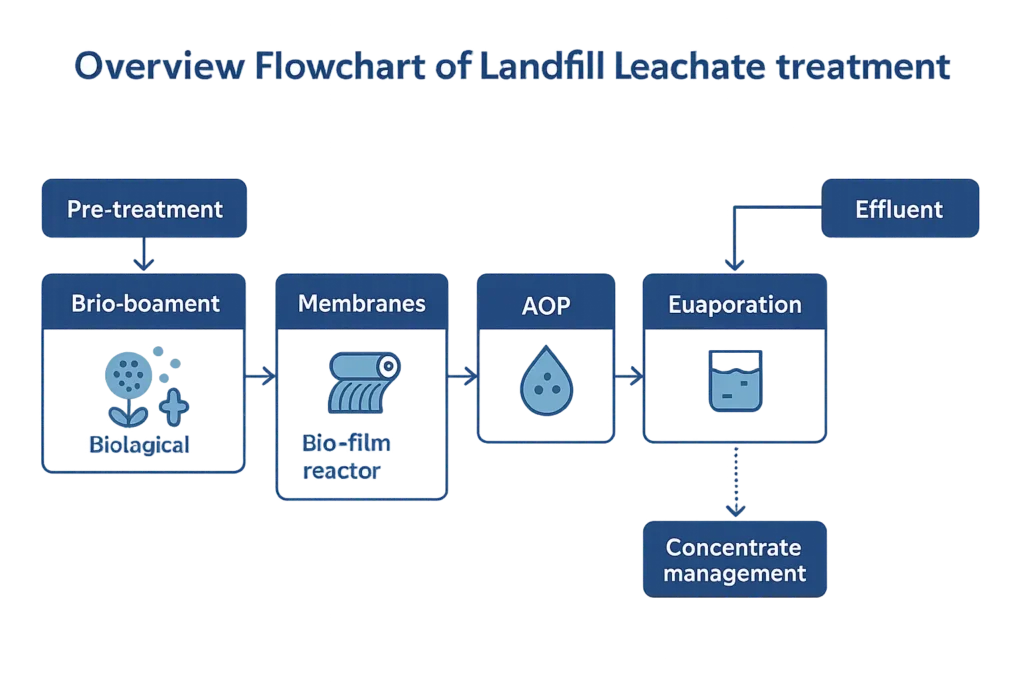

Landfill Leachate Treatment Roadmap

- Pre-treatment: screening → equalization → coagulation/DAF (as needed) → pH control.

- Core stage (select/stack): Biological (UASB/SBR/MBR/A/O/PN/A) - Membranes (UF/NF/RO/DTRO/FO) - Advanced Oxidation (Fenton/O3/UV-PS) - Evaporation (MVR/MVC).

- Polishing: BAF/GAC/O3-bio.

- Concentrate management: crystallization, chemical softening + oxidation, co-processing, ammonium salt recovery.

Landfill Leachate Treatment Options — Side-by-Side Comparison

| Route | Influent Tolerance | N Removal Path | Salt Tolerance | Energie | Chemicaliën | Concentraat | Pros | Cons | Best For |

|---|---|---|---|---|---|---|---|---|---|

| UASB + SBR + CMF + RO | Young–mid leachate; high COD/NH4+-N | Nitrification + denitrification | Moderate (RO limits recovery) | Medium | Medium | ~20–28% | Robust organics removal; mature practice | Multi-stage; RO scaling; concentrate handling | Sites with membrane ops capability |

| MBR + NF/RO | Young–mid; stable feed preferred | Strong nitrification; post-denit needed | Moderate | Medium | Medium | ~20–25% | High effluent stability; compact footprint | Elevated nitrate risk; membrane costs | Parks/new builds targeting reuse |

| Two-Stage DTRO | High-fouling, high salinity | Depends on pre-biological stage | High (fouling-tolerant) | Medium | Laag-Middelmatig | ~20–25% | Compact; rapid deployment | Frequent cleaning; higher CapEx | Space/time-constrained sites |

| No-RO: Physicochemical + A/O + AOP + BAF | Mid–old; variable | Nitrification–denitrification + oxidation | Moderate (watch TDS) | Laag-Middelmatig | Medium | Geen | Stable effluent; avoids RO concentrate | Chemical sludge; salt still impacts biology | Discharge to sewer/surface water |

| Evaporation (MVR/MVC) + IX + Ammonium Recovery | Young–old; very high TDS | Chem/IX polish for N | Very high | Hoog | Laag-Middelmatig | Residual brine remains | Highly stable permeate; ZLD-ready | Scaling/corrosion; power-intensive | Zero/near-zero liquid discharge |

| PN/A (partial nitritation–anammox) | Ammonia-rich sidestreams | Shortcut N removal to N2 | Medium (temp/salt-sensitive) | Laag | Laag | Geen | Large cuts in aeration & carbon | Process control demands; start-up risk | Experienced operators; pilots |

UASB + SBR + CMF + RO

Classic biological + membrane route. Focus on anti-scalant control, RO CIP windows (ΔP/flux triggers), and post-denitrification if nitrate builds up. Plan concentrate handling in design, not as an afterthought.

MBR + NF/RO

MBR delivers solids-free permeate to RO and strong nitrification. Keep DO and sludge age under control; build anoxic zones or dose external carbon to close the TN gap.

Two-Stage DTRO

DTRO tolerates heavy fouling and high TDS; ensure robust pre-filtration and backwash protocols. Expect higher cleaning frequency and plan spare modules and skid accessibility.

No-RO (A/O + AOP + BAF)

Combines coagulation, biological nitrogen removal, oxidation (Fenton/O3/UV-PS), and biological filtration. Attractive when avoiding membrane concentrate is strategic and receiving standards allow it.

Evaporation (MVR/MVC) + IX + Ammonium Salt Recovery

Automation-friendly and highly stable in effluent quality. Pay attention to scaling indices, heat-exchanger metallurgy, antiscalant recipe, and brine crystallization logistics.

Forward-Looking Options

- PN/A: shortcut nitrogen removal with low aeration/carbon; demands tight control of DO, temperature, and nitrite.

- FO–RO hybrids, MABR, monovalent-selective EDR: promising in pilots; evaluate via on-site testing.

Three-Step Selection Framework for Landfill Leachate Treatment

- Define constraints: influent TN/COD/TDS/metals, variability (storm factor), discharge/reuse limits, ZLD need, plot/energy/noise caps.

- Shortlist 2–3 candidates: use a Landfill Age × Salinity × Standard matrix; simulate seasonal cases.

- Techno-economics (LCC): CapEx + Opex (power/chemicals/membranes/carbon) + labor + downtime + concentrate disposal. Run sensitivity on power price and carbon cost.

For international concepts and definitions, see UN SDG water & sanitation context.

Landfill Leachate Treatment Design & Cost Essentials

- Equalization & surge: size for storm events; keep feed steady to core processes.

- Scaling control: check LSI/CSI; dose antiscalant and plan for periodic acid cleaning.

- Energy & chemicals: classify routes as low/medium/high intensity and validate with pilot data.

- Footprint & noise: modular skids, acoustic enclosures, corrosion-proofing.

- Automation: PLC + online sensors (NH4+-N, NO3–-N, TN, ORP, DO, EC); remote alarms and OEE dashboards.

Landfill Leachate Treatment O&M Playbook

- Bewaking: set alarms on NH4+-N, NO3–-N, TN, ORP, DO, EC; track RO ΔP and flux; trend cleaning triggers.

- Carbon management: choose composite carbon vs. methanol/acetate by safety and price; optimize C/N and dose points.

- Sludge control: sludge age (SRT) and recirculation stabilize nitrification; plan dewatering and cake disposal contracts.

- Storm mode: run parallel trains, leverage equalization, and enable temporary bypass dilution where permits allow.

- Membranen: keep spares; standardize CIP SOPs; record cleanings to predict replacement windows.

Concentrate & Residuals Management

Options include evaporation–crystallization, ammonium salt recovery (e.g., sulfate/chloride), chemical softening + AOP for refractory organics, and co-processing routes. A staged approach (salt separation, metals control, organics polishing) improves compliance and logistics.

See an overview on OECD waste and circular economy for policy context.

FAQs — Landfill Leachate Treatment

1) How do I start when NH4+-N is extremely high?

Stabilize with equalization and pH control, then use robust nitrification capacity (MBR/A/O) or consider sidestream PN/A to cut aeration and carbon. Add polishing (BAF or RO/DTRO) to meet TN.

2) Why can MBR+RO show elevated nitrate and how to fix it?

Strong nitrification with insufficient anoxic volume or carbon leads to nitrate carryover. Add anoxic zones, optimize internal recirculation, and dose external carbon where necessary.

3) DTRO vs. evaporation — how to choose?

DTRO suits compact, fast deployment with high-fouling tolerance but produces ~20–25% concentrate. Evaporation delivers highly stable permeate and fits ZLD but is power intensive with scaling control requirements.

4) If we want to avoid RO concentrate, what’s the route?

Use physicochemical + A/O + AOP + BAF and ensure your discharge standard allows this pathway. Concentrate is avoided, but chemical sludge still requires compliant handling.

5) Emergency playbook for storms?

Buffer in equalization, run parallel trains, enable short-term bypass dilution within permit, and pre-position chemicals and spare parts. Monitor EC and nitrogen species closely.

6) Where does PN/A fit?

Best on ammonia-rich sidestreams (e.g., digestate/centrate). It cuts aeration and external carbon but needs tight DO/temperature control and trained operators.

7) Can concentrate be resource-recovered?

Yes—evaporation–crystallization and ammonium salt recovery are feasible. Check market/regulatory acceptance for recovered salts and ensure impurities are controlled.

8) How to estimate unit treatment cost?

Build an LCC: CapEx, power, chemicals, membranes, carbon source, labor, downtime, and concentrate disposal. Run sensitivity on power price and carbon source cost.

9) Which online instruments are essential?

NH4+-N, NO3–-N, TN (lab), DO, ORP, EC, turbidity, and for membranes, ΔP and permeate EC. Set alarm thresholds and maintenance SOPs.

10) Discharge vs. reuse — what’s different?

Reuse targets are typically tighter on TN, color, and EC; often require membrane polishing and activated carbon or oxidation steps to meet aesthetics and stability for industrial reuse.