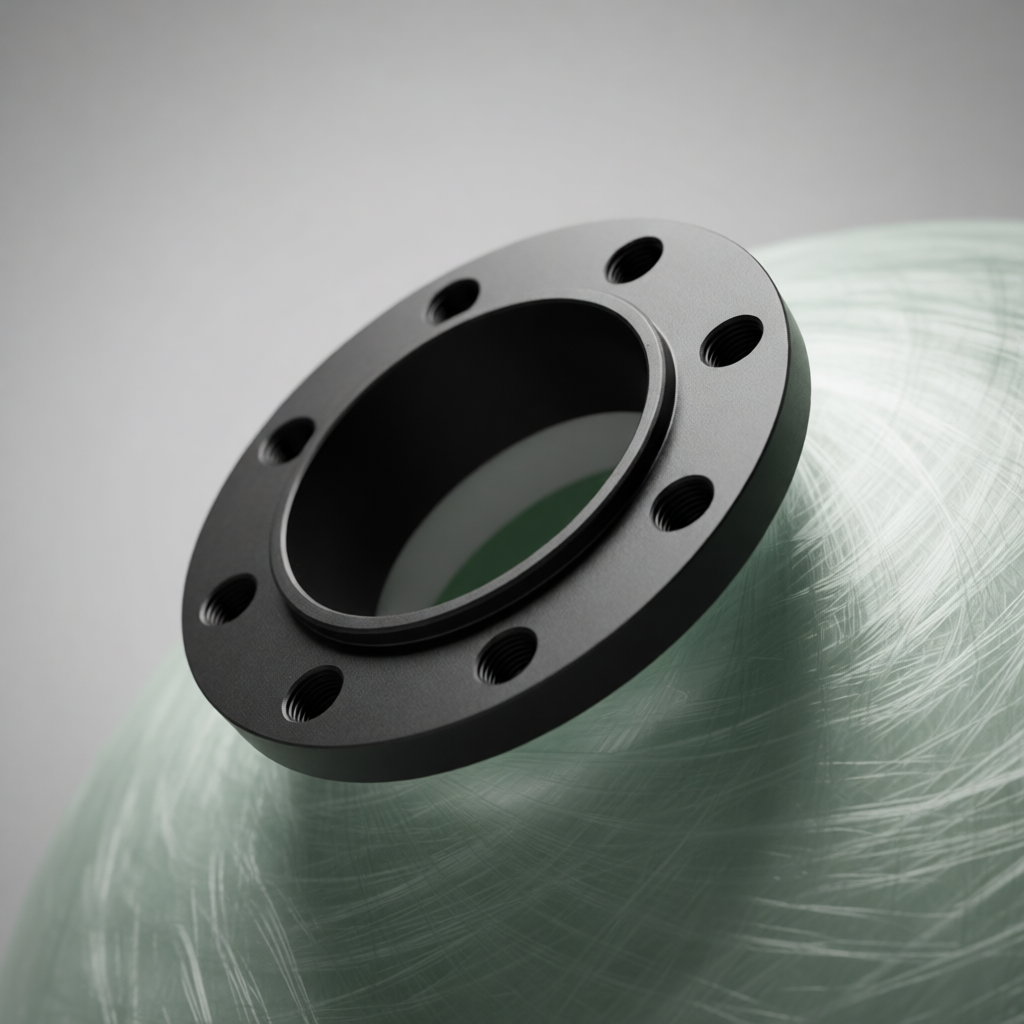

Stark Industrial 6″ Flange Pressure Vessel Series (Heavy Duty)

The Stark industrial **6″ Flange pressure vessel** is engineered for high-volume filtration applications. Featuring a secure 6-inch flange top opening, this heavy-duty tank series (36″-72″ diameter) is designed for municipal water treatment and large-scale industrial plants requiring maximum flow rates and absolutely leak-proof pipe connections.

Product Beschrijving

Engineered for the Toughest Industrial Demands.

The Stark **6″ Flange pressure vessel** series represents the pinnacle of large-scale composite manufacturing. Unlike threaded connections which can be prone to leaks under the stress of large piping systems, our 6-inch flange interface offers a robust, bolted connection point compatible with standard DN150 industrial piping. This ensures zero-leakage performance even under high vibration or pressure surges common in desalination plants and municipal facilities.

Our proprietary multi-axis winding process ensures that even our largest 72-inch vessels maintain structural rigidity and uniform pressure distribution, offering a superior, corrosion-resistant alternative to rubber-lined steel tanks.

Installation & Standard Data:

Proper flange alignment and bolt torque are critical for large vessel safety. For detailed flange dimension drawings (ANSI/DIN), bolt circle specifications, and installation torque guides, please reference the technical documentation at our specialized manufacturing division:

Stark Tank Manufacturing – 6″ Flange Series Technical Specs

.

Product Parameter

Below are the verified specifications for our 6″ Flange top-mount series. These heavy-duty tanks are designed for industrial applications requiring high flow rates.

| Model | Volume Capacity | Dimensions (Dia x H) | Flow Rate (m³/h) | B2B Quote | ||

|---|---|---|---|---|---|---|

| Type | US Gal | Liters | Nominal | mm | (Filter/Softener) | Action |

| STK-3694 | 318.4 | 1205 | 36″ x 94″ | Ø900 x 2465 | 7.6-10 / 12-19 | Inquiry |

| STK-4094 | 351.9 | 1332 | 40″ x 94″ | Ø1000 x 2430 | 9.4-11.7 / 15.7-23.5 | Inquiry |

| STK-4272 | 290.6 | 1100 | 42″ x 72″ | Ø1080 x 1850 | 15-25 / 26-30 | Inquiry |

| STK-4872 | 345.6 | 1308 | 48″ x 72″ | Ø1200 x 1880 | 13.5-17 / 22.6-34 | Inquiry |

| STK-4894 | 504.4 | 1909 | 48″ x 94″ | Ø1200 x 2430 | 13.5-17 / 22.6-34 | Inquiry |

| STK-6083 | 570.1 | 2158 | 60″ x 83″ | Ø1500 x 2120 | 21-27 / 35-53 | Inquiry |

| STK-6094 | 710.2 | 2688 | 60″ x 94″ | Ø1500 x 2430 | 21-27 / 35-53 | Inquiry |

| STK-6383 | 681.6 | 2580 | 63″ x 83″ | Ø1600 x 2100 | 25-45 / 46-56 | Inquiry |

| STK-7294 | 940.8 | 3561 | 72″ x 94″ | Ø1800 x 2400 | 30-40 / 50-76 | Inquiry |

*Note: US dimensions are nominal. Flow rates are for reference only. Please consult our engineers for precise system design.

Toepasselijke industrie

- Gemeentelijke waterzuivering:

Large-scale sand and carbon filtration for city water supplies, removing sediment and contaminants at high throughput. - Zeewaterontzilting:

Pre-treatment filtration for SWRO plants, utilizing corrosion-resistant FRP to withstand aggressive saline environments. - Power Plant Cooling Systems:

Side-stream filtration for cooling towers to reduce suspended solids and prevent heat exchanger fouling.

Voordeel één

Secure Flange Connection

For vessels exceeding 36 inches in diameter, threaded connections are often insufficient. Stark’s 6-inch flange top opening provides a standardized, bolted connection that eliminates the risk of thread stripping or cross-threading during installation.This design allows for the secure attachment of heavy industrial piping (steel or large diameter UPVC) and ensures a reliable seal capable of withstanding system vibration and hydraulic shock.Voordeel TWEE

Massive Capacity, Minimal Maintenance

With diameters up to 72 inches, these vessels hold thousands of liters of media, allowing for extended service runs between backwashes. Unlike traditional rubber-lined steel tanks, Stark FRP vessels are inherently rust-proof and require zero painting or lining maintenance.This significantly reduces the total cost of ownership (TCO) for large-scale projects while providing a service life that often exceeds 10 years in harsh conditions.Verwante producten

Gerelateerde producten

FAQ

V1: Hoe lang gaat het omgekeerde osmose systeem mee?

De levensduur van een omgekeerd osmose systeem hangt af van de waterkwaliteit en het onderhoud. Het membraan gaat meestal 2-3 jaar mee, terwijl het systeem zelf meer dan 10 jaar kan meegaan als het goed onderhouden wordt.

V2: Kan het systeem worden aangepast aan verschillende wateromstandigheden?

Ja, al onze systemen zijn volledig aanpasbaar. We analyseren uw waterrapport en toepassingsbehoeften voordat we oplossingen op maat bieden.

V3: Aan welke normen voldoet de apparatuur van STARK?

Onze producten voldoen aan CE, ISO 9001 en kunnen op verzoek worden ontworpen om te voldoen aan specifieke regionale voorschriften of industrienormen.

V4: Wat is de levertijd voor STARK RO-systemen?

Standaardsystemen worden binnen 7-15 dagen verzonden. Voor aangepaste bestellingen kan de levertijd oplopen tot 20-25 dagen, afhankelijk van de complexiteit.

V5: Biedt u technische ondersteuning of begeleiding bij de installatie?

Ja. We bieden volledige technische documentatie, begeleiding op afstand via video en kunnen op verzoek technici internationaal sturen.

V6: Wat is inbegrepen in jullie offerte?

Onze offerte omvat het volledige RO-systeem, het bedieningspaneel, de pompen, de voorbehandelingsunits en alle benodigde appendages. Installatiegereedschap en reserveonderdelen kunnen op verzoek worden meegeleverd.