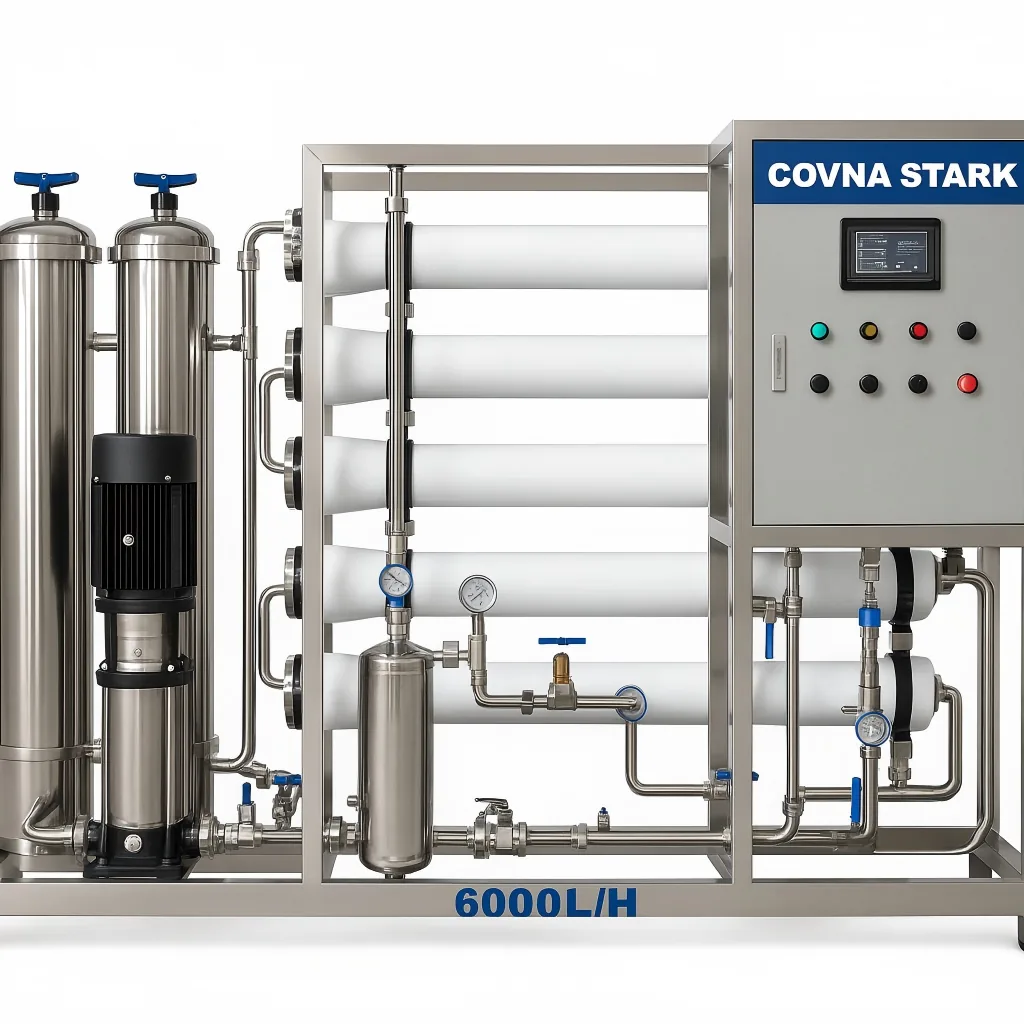

6000LPH RO Waterzuiveringsinstallatie, RO Waterzuiveringsinstallatie met PLC Besturing

6000 LPH RO Water Purification System by STARK delivers stable, low-TDS process water for factories, bottling, and commercial buildings. Skid-mounted design with PLC/HMI, auto-flush, and safety interlocks. Recovery engineered to your feedwater. Request a tailored quote.

Product Beschrijving

De 6000 LPH RO Water Purification System is engineered for continuous industrial service. Using reverse osmosis membranes, it removes dissolved salts, organics, and particles to produce consistent permeate for boiler make-up, ingredient water, and rinsing lines. A typical train combines multimedia and activated-carbon filtration, a 5 μm cartridge, a stainless-steel high-pressure pump, and automatic flush cycles to reduce fouling. PLC/HMI control with low-/high-pressure interlocks improves reliability and simplifies daily operation. Standard recovery is 60–65% and can be tuned to your feed TDS, SDI, and scaling index. Options include a VFD high-pressure pump, 2-pass RO or RO+EDI for ultra-low conductivity, UV/ozone post-treatment, a CIP package, and remineralization. The compact, skid-mounted layout reduces footprint and service time—helping you deploy a scalable, energy-aware industrial RO system across plants.

Designed for reliable, 24/7 operation, the STARK 6000 LPH RO system converts municipal or well water into consistently pure process water. A typical process train includes media filtration / activated carbon, cartridge filtration, high-pressure ROen automatic flush sequences to reduce fouling. The compact skid minimizes footprint while providing front-access to pumps, instrumentation, and membranes for fast service.

Why it works: Reverse osmosis uses a semi-permeable membrane to reject dissolved salts, organics, microorganisms, and particulates—delivering permeate that meets downstream needs (boiler makeup, ingredient water, rinsing, etc.). For most industrial sources, 60–65% recovery is a balanced starting point; higher or lower recovery can be engineered based on feed TDS, temperature, SDI, and scaling indices. (STARK provides on-request feedwater testing and sizing.)

Integration & scalability: The system supports options like VFD high-pressure pump, UV/ozone post-treatment, alkalinity re-mineralization, CIP packageof 2-pass RO / EDI when ultra-low conductivity is required. For multi-site rollouts, STARK offers global technical support and spares logistics through our RO product line.

Product Parameter

| Rated Permeate | 6,000 L/h (configurable) |

|---|---|

| Recovery (single-pass) | 60–65% typical; engineered per feed TDS/SDI/LSI |

| Salt Rejection | 96–99% (membrane-dependent) |

| Voorbehandeling | Multimedia → Activated Carbon → 5 μm cartridge |

| RO-Membranen | 4″ or 8″ elements (brand per BOM) |

| Hogedrukpomp | Stainless-steel multistage, VFD optional |

| Control | PLC/HMI, auto-flush, low/high-pressure interlocks |

| Elektrisch | 380–415 V/50 Hz or 460 V/60 Hz (site standard) |

| Frame & Piping | Stainless-steel skid, SS/UPVC process lines |

Note: Final values are confirmed after feedwater analysis; STARK provides sizing and testing on request.

Toepasselijke industrie

Food & Beverage — ingredient water, CIP make-up

Bottled Water / Beverage — product & rinse water

Pharma / Cosmetics / Lab — pre-polish for DI/EDI

Electronics & Metal Finishing — low-conductivity rinsing

Commercial & Institutional — hospitals, hotels, campuses

Boiler & Cooling Make-Up — scale/corrosion-controlled supply

Voordeel één

Advantage 1 — High-Efficiency, Service-Friendly

Compact skid with clear service access

Auto-flush & safety interlocks reduce fouling risk

VFD-ready high-pressure pump for energy optimization

Modular options: CIP, 2-pass, RO+EDI, UV/ozone, remineralization

Voordeel TWEE

Advantage 2 — Consistent Quality & Expert Support

Stable permeate for critical processes

Engineered recovery to balance water cost vs. fouling

Global spares & remote guidance from STARK

Proven architecture for scalable deployments

Verwante producten

Gerelateerde producten

- Waterzuiveringsinstallatie

160 m³/h UF waterzuiveraar | holle vezel ultrafiltratie | STARK

Lees verder - Omgekeerd osmose systeem

waterzuiveringssystemen omgekeerde osmose RO zuiver waterbehandeling

Lees verder

FAQ

V1: Hoe lang gaat het omgekeerde osmose systeem mee?

De levensduur van een omgekeerd osmose systeem hangt af van de waterkwaliteit en het onderhoud. Het membraan gaat meestal 2-3 jaar mee, terwijl het systeem zelf meer dan 10 jaar kan meegaan als het goed onderhouden wordt.

V2: Kan het systeem worden aangepast aan verschillende wateromstandigheden?

Ja, al onze systemen zijn volledig aanpasbaar. We analyseren uw waterrapport en toepassingsbehoeften voordat we oplossingen op maat bieden.

V3: Aan welke normen voldoet de apparatuur van STARK?

Onze producten voldoen aan CE, ISO 9001 en kunnen op verzoek worden ontworpen om te voldoen aan specifieke regionale voorschriften of industrienormen.

V4: Wat is de levertijd voor STARK RO-systemen?

Standaardsystemen worden binnen 7-15 dagen verzonden. Voor aangepaste bestellingen kan de levertijd oplopen tot 20-25 dagen, afhankelijk van de complexiteit.

V5: Biedt u technische ondersteuning of begeleiding bij de installatie?

Ja. We bieden volledige technische documentatie, begeleiding op afstand via video en kunnen op verzoek technici internationaal sturen.

V6: Wat is inbegrepen in jullie offerte?

Onze offerte omvat het volledige RO-systeem, het bedieningspaneel, de pompen, de voorbehandelingsunits en alle benodigde appendages. Installatiegereedschap en reserveonderdelen kunnen op verzoek worden meegeleverd.