FRP Water Tanks: The Complete Guide & Full Specification List

The ultimate master specification list for Stark **FRP water tanks**. This comprehensive guide covers our entire range of pressure vessels, including standard 2.5″ NPSM residential tanks, high-flow 4″ NPSM commercial models, and heavy-duty 6″ Flange industrial series. Use this catalog to quickly compare dimensions, volumes, and flow rates for any water treatment project.

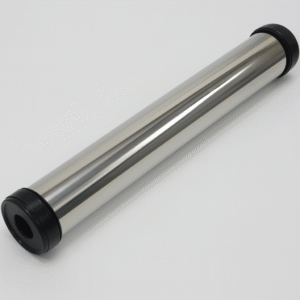

Product Beschrijving

One Source for Every Water Treatment Application.

Whether you are designing a compact home water softener or a massive municipal desalination plant, finding the right pressure vessel is the first step. This master guide consolidates specifications for over 30 different Stark FRP vessel models, ranging from compact 6-liter tanks to massive 3,500-liter industrial reactors.

All Stark tanks are manufactured using our proprietary automated winding process, ensuring consistent wall thickness and a 100% corrosion-resistant HDPE inner liner. This guarantees that whether you choose a small 7×13 tank or a giant 72×94 vessel, you receive the same industrial-grade durability.

Need the Full Data Sheet?

For a downloadable version of this catalog, including detailed structural drawings, shipping weights, and palette packing configurations for every model, please visit our manufacturing division’s resource center:

Stark Tank Manufacturing – Complete Master Spec Sheet

Product Parameter

Below is the complete master specification list for all Stark Water FRP tanks. Use the categorized sections to find the exact opening size and capacity for your system.

| SERIES 1: 2.5″ NPSM Top Mount Models (Residential & Light Commercial) | ||||||

|---|---|---|---|---|---|---|

| Model | Volume | Afmetingen | Debiet (m³/h) | Action | ||

| US Gal | Liters | Inch | mm | Range | ||

| STK-713 | 1.6 | 6 | 7″ x 13″ | Ø180 x 335 | 0.3-0.7 | Inquiry |

| STK-717 | 2.4 | 9 | 7″ x 17″ | Ø180 x 430 | 0.3-0.7 | Inquiry |

| STK-1054 | 16.4 | 62 | 10″ x 54″ | Ø255 x 1390 | 0.6-1.4 | Inquiry |

| STK-1665 | 49.7 | 188 | 16″ x 65″ | Ø400 x 1670 | 1.5-3.8 | Inquiry |

| SERIES 2: 4″ NPSM Top Mount Models (High Flow Commercial) | ||||||

| STK-1465A | 38.6 | 146 | 14″ x 65″ | Ø355 x 1670 | 1.2-3.0 | Inquiry |

| STK-2472 | 109.6 | 415 | 24″ x 72″ | Ø600 x 1920 | 3.3-8.4 | Inquiry |

| STK-3672 | 224.6 | 850 | 36″ x 72″ | Ø900 x 1950 | 7.6-19.0 | Inquiry |

| SERIES 3: 6″ Flange Top/Side Models (Heavy Industrial) | ||||||

| STK-3694 | 318.4 | 1205 | 36″ x 94″ | Ø900 x 2465 | 7.6-19.0 | Inquiry |

| STK-7294 | 940.8 | 3561 | 72″ x 94″ | Ø1800 x 2400 | 30.0-76.0 | Inquiry |

*Note: This is an abbreviated list of our most popular models. For side-mount options or custom sizes, please contact our engineering team.

Toepasselijke industrie

- Residential & Light Commercial (Series 1):

Whole-house softeners, cafe water filtration, and small RO pre-treatment units (up to 3.8 m³/h). - Commercial & Industrial (Series 2):

Hotels, boiler feed water, and mid-sized manufacturing plants requiring high-flow backwashing (up to 23.5 m³/h). - Heavy Industrial & Municipal (Series 3):

Desalination plants, power stations, and city waterworks requiring massive capacity and flange connections (up to 76 m³/h).

Voordeel één

Comprehensive Range, Single Source

Stark Water eliminates the need to source pressure vessels from multiple vendors. By offering a complete spectrum from 6-liter residential tanks to 3,500-liter industrial vessels, we provide system integrators with a unified supply chain.This ensures consistent quality standards, color matching, and warranty terms across your entire project, whether you are building a single home unit or a complex industrial plant.Voordeel TWEE

Consistent Industrial Quality

Unlike competitors who outsource smaller tanks, every Stark FRP vessel—regardless of size—is manufactured with the same rigorous quality control. From the 7″ tank to the 72″ giant, all vessels feature seamless PE liners and high-strength fiberglass winding.All models are rated for 150 PSI operating pressure and undergo strict fatigue testing (100,000 cycles) to guarantee long-term safety.Verwante producten

Gerelateerde producten

FAQ

V1: Hoe lang gaat het omgekeerde osmose systeem mee?

De levensduur van een omgekeerd osmose systeem hangt af van de waterkwaliteit en het onderhoud. Het membraan gaat meestal 2-3 jaar mee, terwijl het systeem zelf meer dan 10 jaar kan meegaan als het goed onderhouden wordt.

V2: Kan het systeem worden aangepast aan verschillende wateromstandigheden?

Ja, al onze systemen zijn volledig aanpasbaar. We analyseren uw waterrapport en toepassingsbehoeften voordat we oplossingen op maat bieden.

V3: Aan welke normen voldoet de apparatuur van STARK?

Onze producten voldoen aan CE, ISO 9001 en kunnen op verzoek worden ontworpen om te voldoen aan specifieke regionale voorschriften of industrienormen.

V4: Wat is de levertijd voor STARK RO-systemen?

Standaardsystemen worden binnen 7-15 dagen verzonden. Voor aangepaste bestellingen kan de levertijd oplopen tot 20-25 dagen, afhankelijk van de complexiteit.

V5: Biedt u technische ondersteuning of begeleiding bij de installatie?

Ja. We bieden volledige technische documentatie, begeleiding op afstand via video en kunnen op verzoek technici internationaal sturen.

V6: Wat is inbegrepen in jullie offerte?

Onze offerte omvat het volledige RO-systeem, het bedieningspaneel, de pompen, de voorbehandelingsunits en alle benodigde appendages. Installatiegereedschap en reserveonderdelen kunnen op verzoek worden meegeleverd.