Kunststof en acryl debietmeter (rotameter) | Stark Water

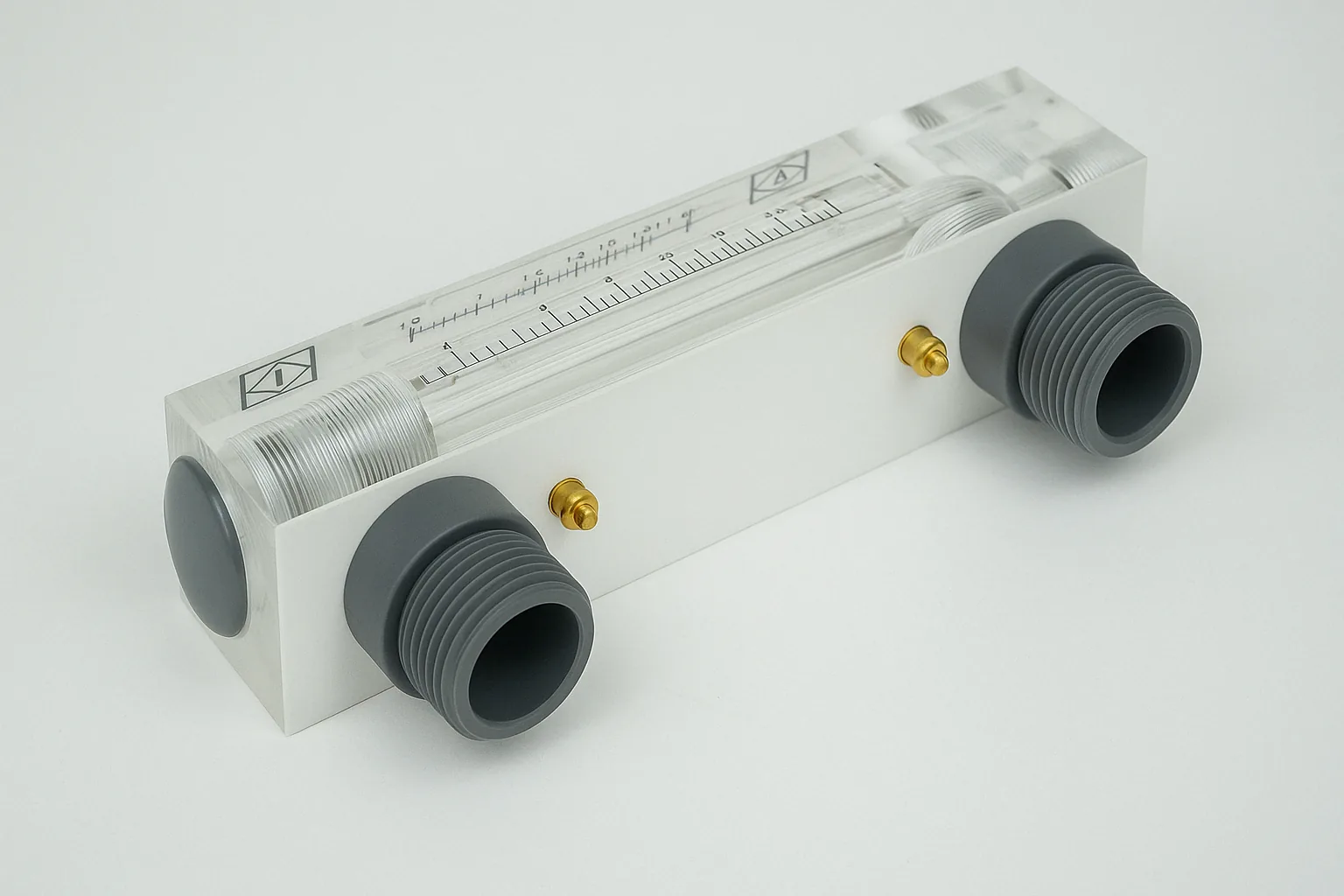

Kunststof acryl debietmeter (rotameter) van STARK geeft een duidelijke, nauwkeurige indicatie van de water- en luchtstroom voor RO-skids, doseerleidingen en HVAC-lussen.

Product Beschrijving

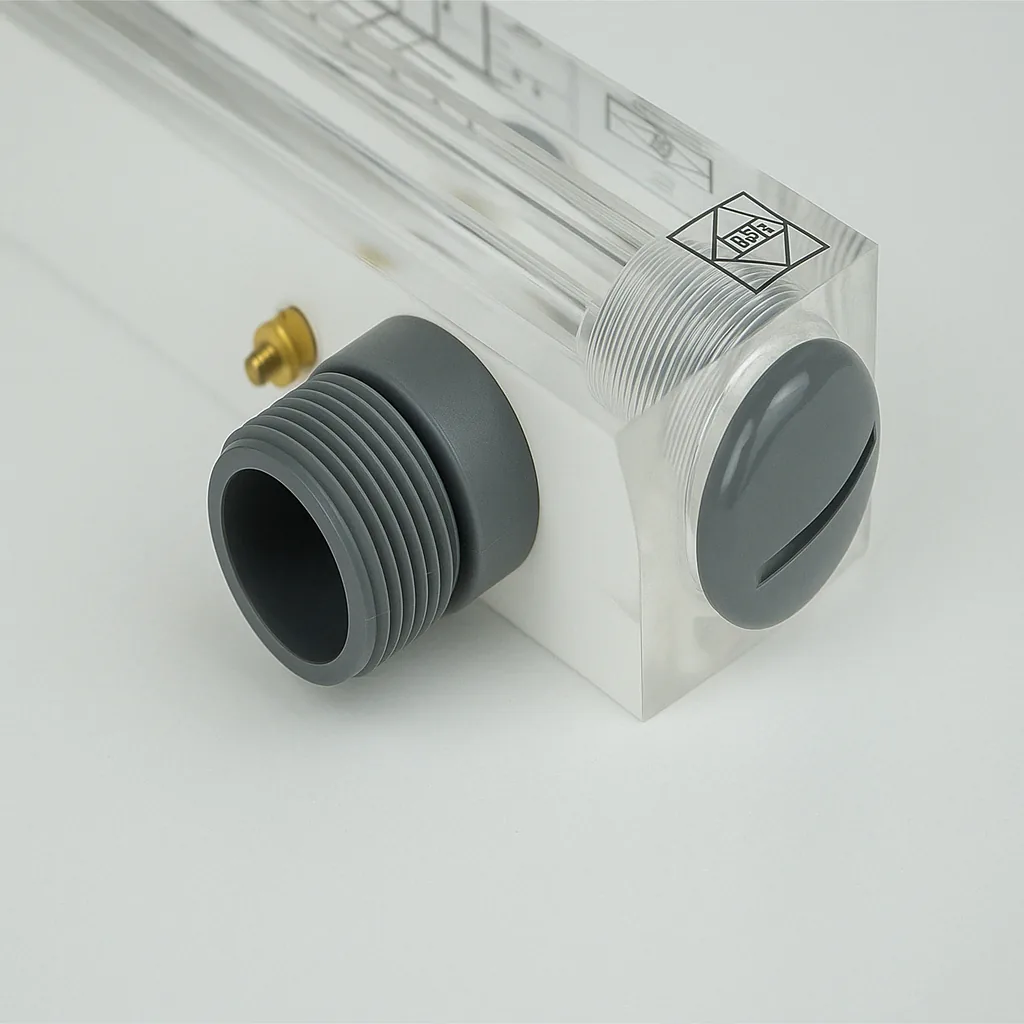

De standaardbehuizingen zijn van PVC of PP met een heldere acrylbuis voor uitstekende afleesbaarheid en schokbestendigheid. De eenheden zijn voorzien van roestvrijstalen of optionele kunststof vlotters (afhankelijk van het bereik), O-ringafdichtingen en verbindingsaansluitingen voor snelle installatie en onderhoud. Kalibratie kan worden geleverd in L/u, L/min, m³/u of GPM om te voldoen aan projectspecificaties.

- Schone schaalafdruk met beschermvenster; optionele dubbele schaal (water/lucht)

- Compacte vormfactor voor paneel- of in-line montage

- Goede chemische compatibiliteit voor typische waterbehandelingsvloeistoffen

- Elke eenheid getest op lekkage en nauwkeurigheid voor verzending

Product Parameter

| Meetprincipe | Variabel oppervlak (rotameter) met vlotter in taps toelopende acrylbuis |

|---|---|

| Media | Water of lucht (andere compatibele vloeistoffen/gassen op aanvraag) |

| Lichaam / buis | PVC of PP behuizing; heldere acrylbuis |

| Vlotter | Roestvrij staal / PTFE / PVC (per debietbereik) |

| Afdichtingen | EPDM standaard; FKM (Viton) optioneel |

| Nominale maten | DN15-DN50 (1/2″-2″) typisch; andere op aanvraag |

| Verbindingen | Unie/schroefdraad of solventgelast; BSP/NPT beschikbaar |

| Doorstroombereiken (water @20 °C) | Ca. 10-100 L/u tot 1-10 m³/u (modelafhankelijk) |

| Nauwkeurigheid | ±4% van volle schaal (typische nauwkeurigheid rotameter) |

| Maximale druk | 0,6-1,0 MPa afhankelijk van grootte en materiaal |

| Max. temperatuur | 0-60 °C (raadpleeg STARK voor hoger of chemisch gebruik) |

| Montage | Verticale installatie, stroom van onder naar boven |

| Naleving | Gefabriceerd onder STARK QA; druk/lek getest |

Opmerking: De definitieve BOM (buislengte, vlottermateriaal, schaaleenheden en eindaansluitingen) wordt bevestigd nadat uw procesdatasheet is bekeken.

Toepasselijke industrie

- Omgekeerde osmose skids - permeaat- en concentraatbewaking

- Zand/koolstoffilters - terugspoel- en spoelstroomcontroles

- Chemische doseersystemen - coagulant/antiscalant lijnen

- Koelwater- en HVAC-lussen - visuele stroombevestiging

- Persluchtdistributie - balanceren van aftakkingen

- Laboratorium- en proeffabrieken - snelle installatie en verificatie

Voordeel één

Voordeel 1 - Duidelijke, betrouwbare indicatie

- Acrylbuis met hoge helderheid, bedrukte schaal en referentie aanwijzer

- Eenvoudig mechanisch ontwerp - geen voeding nodig

- Uniale uiteinden voor snelle installatie en onderhoud

- Meerdere schaalopties (L/u, L/min, m³/u, GPM) en aangepast logo

Voordeel TWEE

Voordeel 2 - Robuuste materialen & ondersteuning

- Behuizing van PVC/PP en corrosiebestendige bevochtigde onderdelen

- EPDM- of FKM-afdichtingen die passen bij uw chemische omstandigheden

- Lekkage/nauwkeurigheidstests in de fabriek en beschikbaarheid van reserveonderdelen

- Wereldwijde technische ondersteuning en snelle levertijd van STARK

Verwante producten

Gerelateerde producten

FAQ

V1: Hoe lang gaat het omgekeerde osmose systeem mee?

De levensduur van een omgekeerd osmose systeem hangt af van de waterkwaliteit en het onderhoud. Het membraan gaat meestal 2-3 jaar mee, terwijl het systeem zelf meer dan 10 jaar kan meegaan als het goed onderhouden wordt.

V2: Kan het systeem worden aangepast aan verschillende wateromstandigheden?

Ja, al onze systemen zijn volledig aanpasbaar. We analyseren uw waterrapport en toepassingsbehoeften voordat we oplossingen op maat bieden.

V3: Aan welke normen voldoet de apparatuur van STARK?

Onze producten voldoen aan CE, ISO 9001 en kunnen op verzoek worden ontworpen om te voldoen aan specifieke regionale voorschriften of industrienormen.

V4: Wat is de levertijd voor STARK RO-systemen?

Standaardsystemen worden binnen 7-15 dagen verzonden. Voor aangepaste bestellingen kan de levertijd oplopen tot 20-25 dagen, afhankelijk van de complexiteit.

V5: Biedt u technische ondersteuning of begeleiding bij de installatie?

Ja. We bieden volledige technische documentatie, begeleiding op afstand via video en kunnen op verzoek technici internationaal sturen.

V6: Wat is inbegrepen in jullie offerte?

Onze offerte omvat het volledige RO-systeem, het bedieningspaneel, de pompen, de voorbehandelingsunits en alle benodigde appendages. Installatiegereedschap en reserveonderdelen kunnen op verzoek worden meegeleverd.