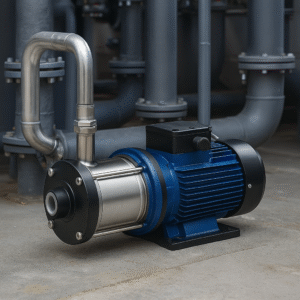

STARK Vertical multistage centrifugal pump With 7.5kw Hight Pressure And 1hp Motor

STARK’s vertical multistage centrifugal pump is built for high-pressure applications in water treatment and industrial fluid handling. Equipped with a 7.5kW primary motor and 1HP auxiliary motor, it delivers stable flow, compact structure, and efficient performance for RO systems and beyond.

Product Beschrijving

Reliable and Efficient Vertical Multistage Centrifugal Pump for Industrial Use

De Vertical Multistage Centrifugal Pump from STARK is engineered to deliver high pressure and stable performance in water supply, reverse osmosis, and process circulation systems. Its stacked impeller structure provides multi-stage pressure boosting within a compact vertical footprint, reducing installation space and enhancing energy efficiency.

Featuring a robust stainless steel hydraulic section, the pump resists corrosion and erosion even under demanding operational conditions. The 7.5kW motor ensures powerful water lifting, while the auxiliary 1HP motor supports system control or secondary functions depending on project requirements.

Belangrijkste kenmerken:

- Vertical multistage design with minimal floor space requirement

- Precision-cast stainless steel components for long service life

- Energy-efficient 7.5kW motor with high pressure output

- Integrated 1HP auxiliary motor for intelligent control or redundancy

- Low noise, low vibration, and high sealing reliability

- Compatible with RO, boiler feed, pressure boosting, and industrial circulation systems

Product Parameter

| Parameter | Specificatie |

|---|---|

| Productnaam | Vertical Multistage Centrifugal Pump |

| Primary Motor Power | 7.5 kW |

| Auxiliary Motor | 1 HP (0.75 kW) |

| Pomptype | Vertical, multistage, centrifugal |

| Materiaal | Stainless steel impellers and casing |

| Debiet | Up to 20 m³/h (customizable) |

| Head (Pressure) | Up to 100 meters |

| Inlet/Outlet Connection | DN40 – DN65 flange/thread |

| Operating Voltage | 380V / 50Hz / 3 phase (customizable) |

| Sealing System | Mechanical seal, anti-leak design |

| Installatie | Vertical, floor-mounted |

Toepasselijke industrie

- Reverse osmosis (RO) systems – high-pressure membrane feed

- Boiler feedwater supply and pressure boosting

- Industrial process circulation (chemical, textile, food)

- High-rise building and commercial water supply

- Water treatment and wastewater pressurization

- Cooling tower and chiller water circulation

- Fire-fighting water systems

Voordeel één

Compact Vertical Design with High Output Pressure

The multistage vertical configuration allows for high-pressure output without occupying excessive floor space. Ideal for equipment rooms and modular skid systems where space optimization and performance are equally important.Voordeel TWEE

Durable Stainless Steel Construction and Long Service Life

Key hydraulic components are made from corrosion-resistant stainless steel, providing excellent wear resistance and chemical stability. This ensures reliable operation over extended periods, even under harsh fluid conditions in industrial water treatment systems.Verwante producten

Gerelateerde producten

FAQ

V1: Hoe lang gaat het omgekeerde osmose systeem mee?

De levensduur van een omgekeerd osmose systeem hangt af van de waterkwaliteit en het onderhoud. Het membraan gaat meestal 2-3 jaar mee, terwijl het systeem zelf meer dan 10 jaar kan meegaan als het goed onderhouden wordt.

V2: Kan het systeem worden aangepast aan verschillende wateromstandigheden?

Ja, al onze systemen zijn volledig aanpasbaar. We analyseren uw waterrapport en toepassingsbehoeften voordat we oplossingen op maat bieden.

V3: Aan welke normen voldoet de apparatuur van STARK?

Onze producten voldoen aan CE, ISO 9001 en kunnen op verzoek worden ontworpen om te voldoen aan specifieke regionale voorschriften of industrienormen.

V4: Wat is de levertijd voor STARK RO-systemen?

Standaardsystemen worden binnen 7-15 dagen verzonden. Voor aangepaste bestellingen kan de levertijd oplopen tot 20-25 dagen, afhankelijk van de complexiteit.

V5: Biedt u technische ondersteuning of begeleiding bij de installatie?

Ja. We bieden volledige technische documentatie, begeleiding op afstand via video en kunnen op verzoek technici internationaal sturen.

V6: Wat is inbegrepen in jullie offerte?

Onze offerte omvat het volledige RO-systeem, het bedieningspaneel, de pompen, de voorbehandelingsunits en alle benodigde appendages. Installatiegereedschap en reserveonderdelen kunnen op verzoek worden meegeleverd.