Reading time: 10–14 minutes · Audience: industrial water engineers, EPC contractors, equipment buyers, O&M teams

Executive summary: Eine industrial pure water system is a complete package that uses reverse osmosis (RO) technology and pretreatment filters to produce high-quality purified water for factories, laboratories and power plants. This article explains the RO working principle, walks through a typical process flow from raw water tank to pure water tank, and introduces key components such as multimedia filter, activated carbon filter, security filter, high-pressure pump and RO membranes. It is written as a practical guide for engineers and purchasers who need to understand what is inside an RO pure water system and how to specify one correctly.

1. What Is an Industrial Pure Water System?

Eine industrial pure water system (also called RO pure water equipment, deionized water system or RO water purification system) is a skid-mounted treatment line that removes suspended solids, organic matter and dissolved salts from raw water to meet process requirements. Compared with household drinking-water purifiers, industrial systems:

- Handle much higher flow rates, typically from 0.5 m³/h to several hundred m³/h.

- Operate continuously 24/7 under automatic control.

- Are designed around long-term stability, redundancy and ease of maintenance.

Industrial pure water is widely used in electronics manufacturing, pharmaceuticals, food and beverage, plating lines, laboratories and boiler feed water. The exact configuration can be tailored to the client’s raw water quality and product water standards.

2. RO Technology and Working Principle

Reverse osmosis (RO) is the core technology in most modern pure water systems. RO uses a semi-permeable membrane with an effective pore size of around 0.0001 µm to separate water molecules from dissolved salts and other contaminants.

Under natural conditions, water tends to move from low-salinity to high-salinity solutions through a membrane—this is normal osmosis. In an industrial pure water system we apply high pressure, greater than the osmotic pressure, on the concentrated side. This reverses the natural flow, forcing relatively pure water (permeate) through the membrane while leaving salts, organics and microorganisms in the concentrate (brine).

Key performance indicators for RO include:

- Salt rejection: typically 95–99 % for monovalent salts and even higher for multivalent ions.

- Recovery rate: the fraction of feedwater converted to permeate, often 50–75 % in a single-pass system.

- Permeate conductivity or resistivity: a direct measure of ionic purity.

Because RO removes contaminants by physical separation at ambient temperature, it consumes much less energy than thermal distillation and does not require chemical regenerants like traditional ion-exchange softening and deionization.

3. Typical Process Flow of an Industrial Pure Water System

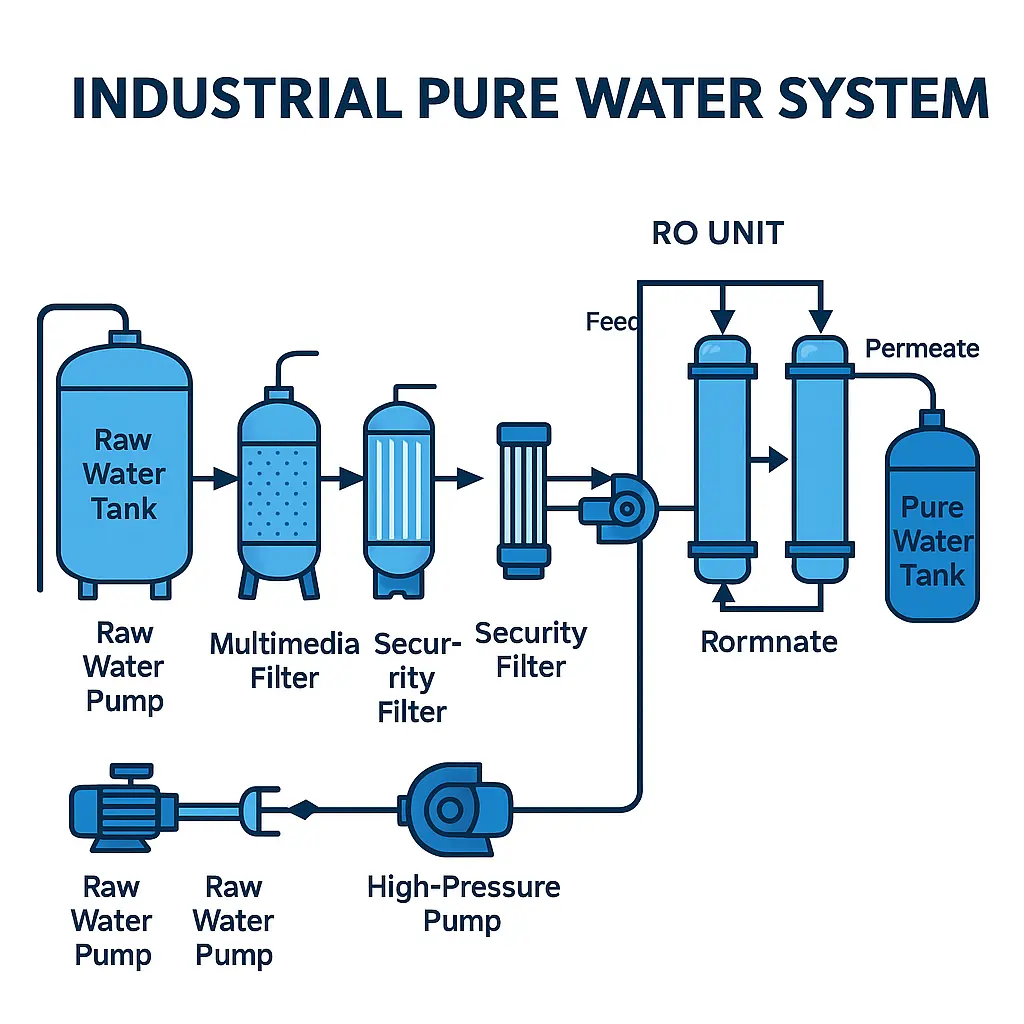

Although every project is custom-designed, many industrial pure water systems follow a similar process flow:

- Raw water tank → raw water pump

- Quartz sand (multimedia) filter

- Activated carbon filter

- Optional softener or antiscalant dosing

- Security (cartridge) filter

- Hochdruckpumpe

- RO membrane system (single-pass or double-pass)

- Pure water tank → distribution loop

The pretreatment section focuses on removing suspended solids, chlorine and hardness to protect the RO membranes. The RO section performs the main desalination. The pure water tank and distribution loop then deliver stable quality water to the points of use.

4. Key Components of an Industrial Pure Water System

4.1 Raw Water Tank and Raw Water Pump

The raw water tank equalizes flow and pressure fluctuations from the incoming water source, whether it is city tap water, well water or surface water. It also provides a buffer volume to prevent the RO skid from frequent start-stop cycles.

The raw water pump draws from this tank and supplies stable pressure to the subsequent pretreatment filters. For small systems this is often a horizontal centrifugal pump; for larger plants it may be a vertical multistage pump with variable-frequency drive (VFD).

4.2 Quartz Sand (Multimedia) Filter

The multimedia filter is a vertical FRP or steel vessel filled with graded quartz sand and sometimes anthracite or garnet. It removes:

- Suspended solids, silt and clay particles

- Rust and scale flakes

- Colloidal turbidity

By reducing turbidity and SDI (silt density index), the multimedia filter protects downstream activated carbon and RO membranes from plugging. The vessel is equipped with automatic backwash and rinse cycles controlled by a timer or differential-pressure switch.

4.3 Activated Carbon Filter

The activated carbon filter uses high-iodine-value granular activated carbon (GAC) to remove:

- Free chlorine and combined chlorine (to prevent oxidative damage to RO membranes)

- Color, odor and taste-causing compounds

- Some organic micro-pollutants

Like the sand filter, the carbon filter is periodically backwashed and rinsed to prevent channeling and maintain adsorption efficiency. In many designs, sodium bisulfite dosing is added downstream as an extra safeguard for dechlorination.

4.4 Optional Water Softener or Antiscalant Dosing

For high-hardness feedwater, a softener (cation exchange resin) may be installed to remove Ca²⁺ and Mg²⁺. Alternatively, an antiscalant dosing system injects a proprietary inhibitor upstream of the RO to control calcium carbonate, sulfate and silica scaling. The choice depends on raw water analysis, recovery target and OPEX comparison.

4.5 Security Filter (Cartridge / Precision Filter)

The security filter—also known as a cartridge or precision filter—is the last barrier before the RO membranes. It usually contains multiple 5 µm or 1 µm PP melt-blown cartridges in a stainless-steel housing. Its functions are to:

- Remove fine particles, rust, resin fines and any debris from upstream filters.

- Protect the narrow feed channels of the RO membranes from plugging.

- Provide an early-warning point: frequent cartridge plugging indicates pretreatment issues.

4.6 High-Pressure Pump

The RO high-pressure pump increases feed pressure to 10–20 bar for brackish water systems and higher for seawater. It is the main energy consumer in an industrial pure water system. Variable-frequency drives are often used to balance energy consumption with operating conditions.

4.7 RO Membrane System

The RO section consists of pressure vessels (membrane housings) loaded with spiral-wound membrane elements. Common configurations include 4″×40″ elements for small flow rates and 8″×40″ elements for larger plants. Vessels are arranged into stages (e.g., 2:1 or 3:2) to balance recovery and flux.

The RO system produces two streams:

- Permeate (product water): low-salinity water that flows to the pure water tank.

- Concentrate (brine): high-TDS stream that is discharged or reused for lower-quality applications.

Depending on required water quality, options include single-pass RO, double-pass RO (RO–RO), or RO followed by mixed-bed / EDI polishing.

4.8 Pure Water Tank and Distribution Loop

The pure water tank stores permeate and decouples RO production from downstream demand. A separate distribution pump (or pumps) sends water to points of use through a loop equipped with UV disinfection and fine filtration. Continuous recirculation helps maintain low microbial counts and stable conductivity.

5. Performance Targets and Design Considerations

When specifying an industrial pure water system, engineers should define clear design targets:

- Product water quality: typical specifications are conductivity ≤10 µS/cm for general process water, ≤1 µS/cm for sensitive electronics or as a pretreatment for EDI.

- Flow rate and diversity factor: maximum instantaneous demand, average load and future expansion margin.

- Recovery rate and concentrate management: balance water efficiency with scaling risk and discharge regulations.

- Raw water envelope: TDS, hardness, SDI, iron, manganese, organic matter, chlorine and microbiology.

Proper design also considers instrument placement (flow, pressure, conductivity, ORP), automatic interlocks and cleaning connections so that the system is easy to monitor and maintain.

6. Advantages of RO-Based Industrial Pure Water Systems

- High desalination efficiency: a single-pass RO can remove 95–99 % of dissolved salts, with double-pass or polishing reaching ultra-low conductivity.

- Lower operating cost: energy is mainly electrical power for pumps, with no acid/alkali regenerants like conventional ion-exchange systems.

- Modular and scalable: additional trains or vessels can be added as plant demand grows.

- Environmentally friendlier: no regeneration wastewater with high TDS and chemical content.

- Stable and automated: PLC or DCS control allows unattended operation with built-in alarms and protections.

7. Operation, Maintenance and Common Troubleshooting Points

7.1 Routine Operation and Preventive Maintenance

- Backwash and rinse multimedia and carbon filters according to ΔP or timer.

- Replace cartridge filters when pressure drop becomes excessive or at a fixed running-hour interval.

- Check and record key operating data: flows, pressures, temperature and conductivities.

- Verify dechlorination and antiscalant dosing, especially after chemical deliveries or maintenance.

7.2 When to Clean RO Membranes

Typical cleaning triggers include:

- Normalized permeate flow decreases by 10–15 % from baseline.

- Normalized differential pressure increases by 15–20 %.

- Salt passage (1 / rejection) increases consistently.

Cleaning frequency depends on feedwater quality and operation discipline. A well-designed pretreatment and operating window can significantly extend membrane life.

7.3 Common Problems and Quick Checks

- Sudden permeate conductivity spike: check for O-ring failure, cartridge damage or accidental cleaning-solution carryover.

- Rapid pressure increase across pretreatment: verify backwash sequence and look for mud or biofouling.

- Frequent low-level alarms on tanks: review raw water supply stability and consider adding buffer volume.

8. Typical Applications for Industrial Pure Water Systems

Industrial pure water systems based on RO are widely used in:

- Electronics and semiconductor manufacturing: rinsing, PCB production and cleaning processes.

- Pharmaceutical and biotech plants: as pretreatment for purified water and WFI systems.

- Power plants and boiler houses: boiler make-up water, turbine washing and condensate polishing.

- Food and beverage: ingredient water, CIP rinsing and beverage blending.

- Surface treatment and plating lines: rinse tanks and final wash steps.

- Laboratories and pilot plants: general analytical water and pilot process feed.

9. How to Select the Right Industrial Pure Water System

When evaluating suppliers and designs, consider the following points:

- Whether the system is designed based on a complete water analysis and clear product water specification.

- The quality and brand of critical components such as RO membranes, high-pressure pumps, pressure vessels and instruments.

- The level of automation, remote monitoring options and availability of local service.

- Experience and references of the supplier in your industry (electronics, pharma, power, etc.).

- Total lifecycle cost: not only initial investment but also expected chemical consumption, cleaning frequency and membrane replacement intervals.

A well-engineered industrial pure water system should provide stable, consistent water quality with predictable operating costs over many years. Taking the time to specify the right process flow and components at the beginning will pay off in fewer production interruptions and lower O&M workload.