In the lifecycle of any industrial Reverse Osmosis (RO) system, fouling is inevitable. As contaminants accumulate on the membrane surface, you will notice a significant drop in permeate flow and a rise in pump pressure.

The key to restoring performance lies in a successful Clean-In-Place (CIP) operation. However, choosing the wrong RO membrane cleaning chemicals can turn a minor maintenance issue into a permanent failure.

This guide explains the industry-standard differences between Acidic and Alkaline cleaning, helping you select the effective RO membrane cleaning chemicals for your specific water conditions.

Quick Diagnostic: If your membrane performance has dropped by more than 15% (normalized flow) or pressure has increased by 15%, it is time to clean. Waiting longer makes fouling irreversible.

Diagnosing Fouling Before Choosing RO Membrane Cleaning Chemicals

Before mixing any solutions, you must identify what is clogging your elements. The effectiveness of your RO membrane cleaning chemicals depends entirely on matching the chemical to the foulant type.

- Inorganic Fouling (Scaling): Caused by mineral deposits like Calcium Carbonate (CaCO3), Calcium Sulfate, and metal oxides.

Die Symptome: Often occurs on the last stage of the RO system where concentration is highest. - Organic & Biological Fouling: Caused by bacteria, algae, slime, oils, and colloidal matter.

Die Symptome: Often occurs on the first stage (lead elements) resulting in a rapid pressure drop.

1. Acidic Cleaning Chemicals (Low pH)

Target: Inorganic Scale (Minerals, Iron)

Acid cleaning is specifically designed to dissolve mineral scales by lowering the pH. This process converts insoluble salts into soluble forms that can be flushed away.

Common Industry Formulas:

- Citric Acid (2.0% Solution): The most common choice among RO membrane cleaning chemicals. It is effective for Calcium Carbonate and Iron. Adjust pH to 2.0–3.0.

- Hydrochloric Acid (HCl): Used for severe mineral scaling, typically diluted to 0.1% strength.

Critical Warning: Do not use Sulfuric Acid if Calcium is present, as it can cause Calcium Sulfate precipitation, which is extremely difficult to remove.

2. Alkaline Cleaning Chemicals (High pH)

Target: Organics, Bio-slime, Oils, Silica

Alkaline cleaning uses high pH solutions to hydrolyze organic matter and break down biological slime layers attached to the membrane surface.

Common Industry Formulas:

- Sodium Hydroxide (NaOH): Also known as Caustic Soda. Typically used at 0.1% concentration. Adjust pH to 11.0–12.0.

- Sodium Tripolyphosphate (STPP): Added as a chelating agent to assist the detergent action.

Note: Always ensure the cleaning solution temperature does not exceed 45°C (113°F) when using high pH chemicals.

The Golden Rule: Acid or Alkaline First?

If you suspect your water contains both biological matter and mineral scale, the order of application is critical for the success of your RO membrane cleaning chemicals.

Industry Standard: Clean Alkaline First.

Why? If you introduce acid to a membrane covered in biological slime, the acid can harden the slime layer (like cooking an egg), making it impossible to remove. Always remove the organic biofilm with an Alkaline clean before attacking the mineral scale with Acid.

When Cleaning Fails: Signs You Need Replacement

Even the best RO membrane cleaning chemicals cannot repair physical damage. If you have performed a thorough CIP cycle and still observe low salt rejection or high pressure drops, the membrane has likely reached the end of its service life.

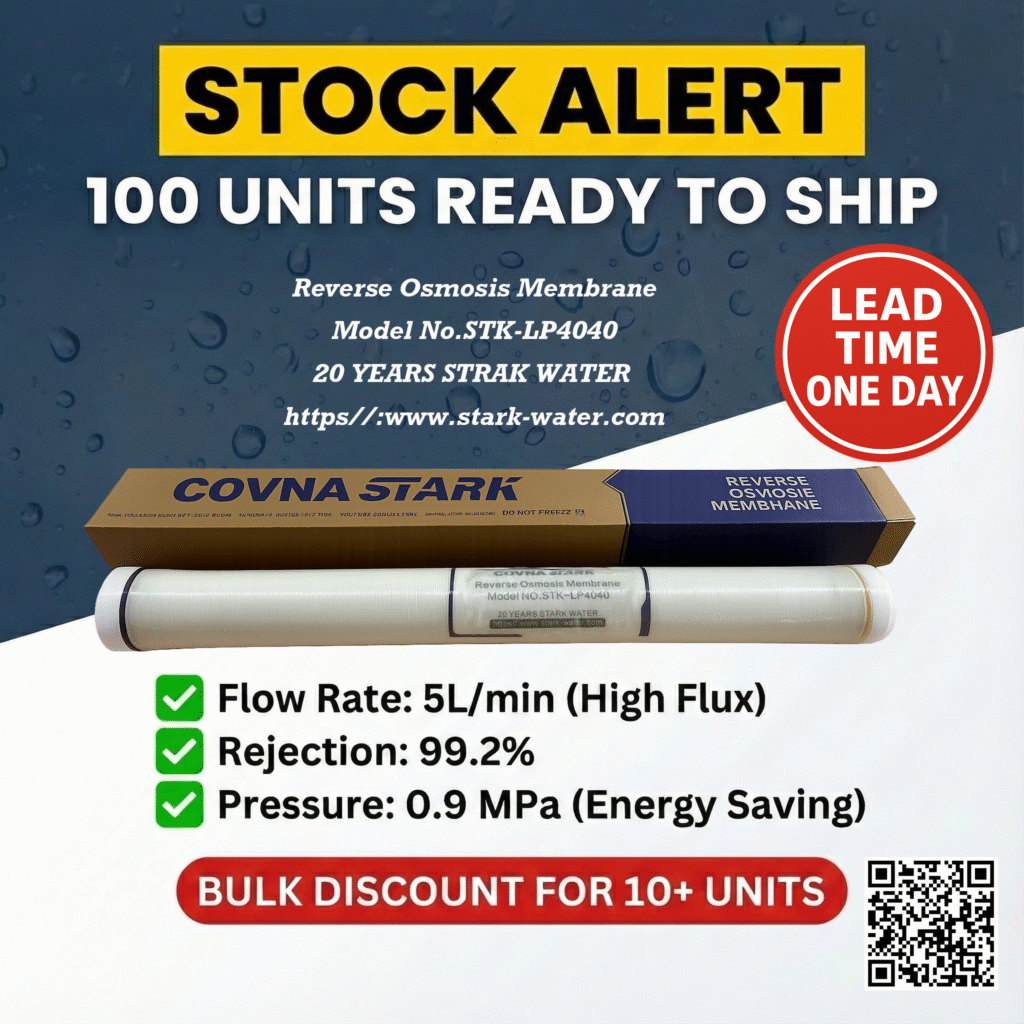

Upgrade to High-Flux Membranes (Ready to Ship)

If cleaning is no longer effective, Stark Water offers a high-performance replacement solution.

- High Flow: 5L/min output.

- Energy Saving: Operates at low pressure (0.9 MPa).

- Availability: 100 Units In Stock for immediate dispatch.

Check our latest stock update or view the product specifications below:

View In-Stock 4040 Sale Event

View LP-4040 Product Details & Specs

Schlussfolgerung

Proper maintenance is a science. By correctly identifying the foulant and selecting the right RO membrane cleaning chemicals, you can significantly extend your system’s uptime.

Need specific advice on your CIP procedure? Contact Stark Water engineers today.