Last updated: November 6, 2025 · Reading time: 10–14 minutes · Audience: RO operators, plant managers, EPCs

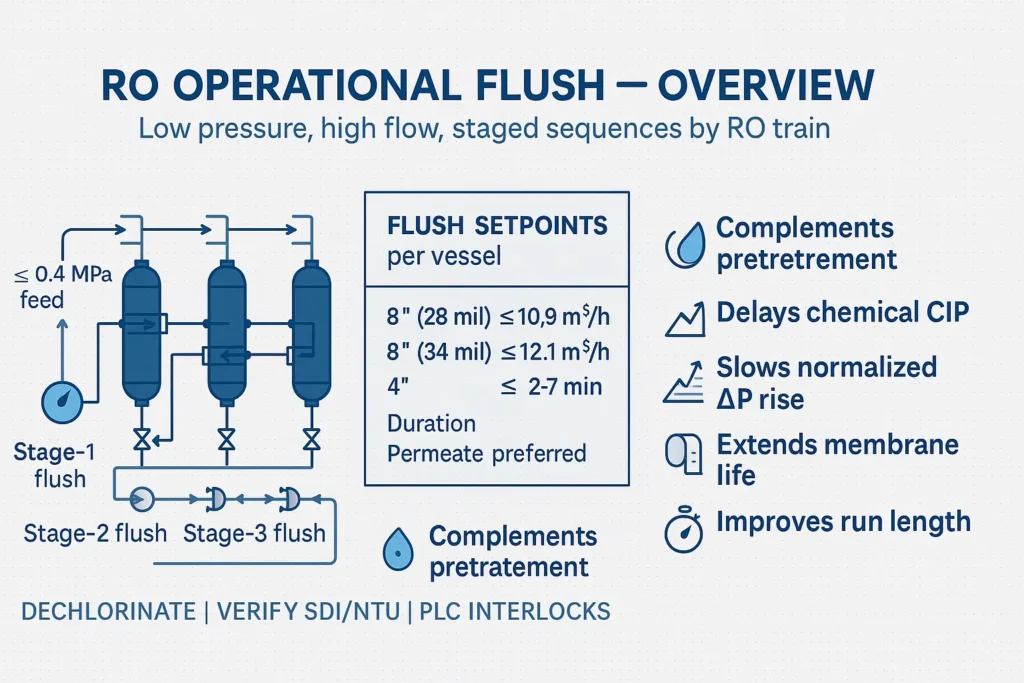

An effective RO operational flush is a low-pressure, high-flow sweep that removes loosely attached foulants without chemicals. Done right, it slows normalized ΔP rise, extends run length, and cuts CIP frequency—improving membrane life and lowering OPEX.

What Is an Operational Flush (vs. Rinse & CIP)?

- Operational flush: short, scheduled or event-based, low pressure & high flow using permeate (preferred) or filtered feed to sweep the membrane surface.

- Rinse: brief displacement after chemical steps or start/stop; not intended to remove foulants.

- CIP: chemical cleaning (acid/alkali/enzymatic) when flushing no longer restores performance thresholds.

Goal: stabilize normalized flux and ΔP so that CIP is needed less often and membranes last longer.

Target Setpoints — Flow, Pressure, Time, Water Source

Use ranges below as a starting point and confirm with your membrane vendor and piping limits.

| Membrane size | High-flow limit (per vessel) | Flush pressure (feed) | Duration (per stage) | Preferred water |

|---|---|---|---|---|

| 8″ (28 mil spacer) | ≤ 10.9 m³/h | As low as practicable; ≤ 0.4 MPa | 3–10 min | Permeate (best) → filtered feed (OK if SDI/NTU low, dechlorinated) |

| 8″ (34 mil spacer) | ≤ 12.1 m³/h | As low as practicable; ≤ 0.4 MPa | 3–10 min | Permeate / filtered feed as above |

| 4″ | ≤ 2.7 m³/h | As low as practicable; ≤ 0.4 MPa | 3–10 min | Permeate / filtered feed as above |

Why low pressure? High pressure can compress/deposit foulants into the surface; the flush should maximize shear at minimal trans-membrane pressure.

How Often Should an RO Operational Flush Run?

- Baseline: once per day per train is a practical starting point.

- Event triggers: normalized ΔP slope > 4–5%/week, SDI/NTU spikes (storms/filters), or stand-by > 2–4 h.

- Seasonal: increase frequency in warm seasons due to biofouling risk.

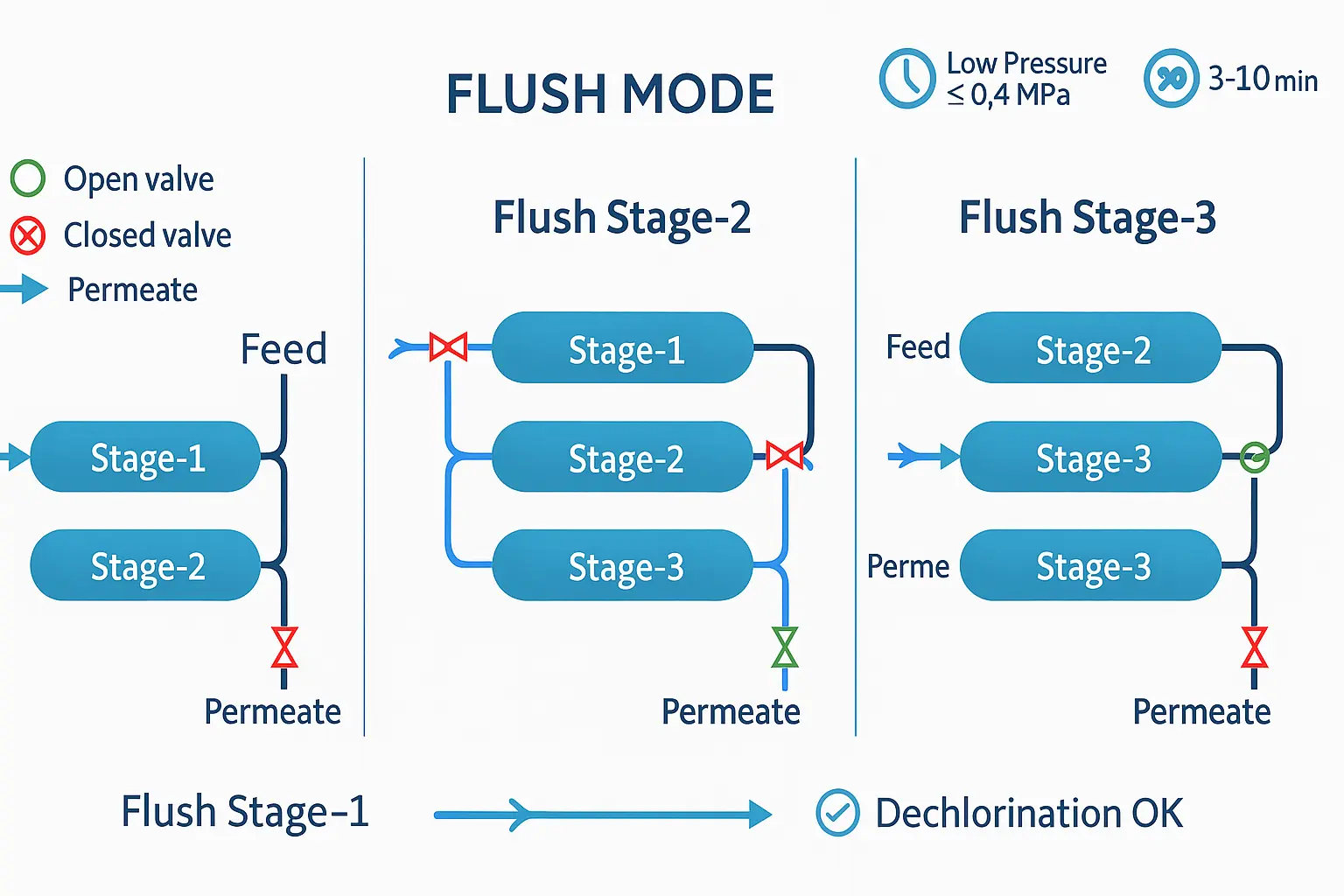

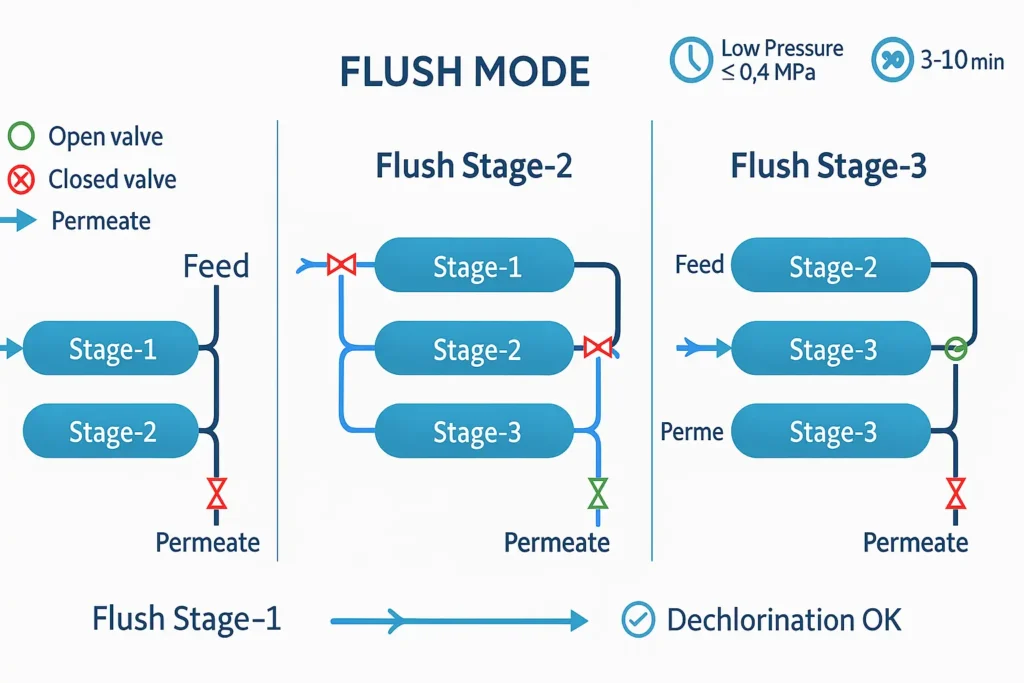

Staged Flushing & Valve Logic (Multi-Stage RO)

Spülen stage by stage to avoid pushing front-stage solids into later stages and to keep pressure caps safe on long trains.

Example Sequences (3-Stage Train)

- Flush Stage-1: Open Stage-1 concentrate discharge fully; close Stage-1→2 interstage valve; keep Stage-2/3 flush inlets closed. Run at target flow, ≤ 0.4 MPa for 3–10 min.

- Flush Stage-2: Open Stage-2 concentrate discharge; close Stage-1↔2 and Stage-2↔3 interstage valves; Stage-1/3 flush inlets closed; run 3–10 min.

- Flush Stage-3: Open Stage-3 concentrate discharge; close Stage-2↔3 interstage; Stage-1/2 inlets closed; run 3–10 min.

Piping note: Concentrate line and valves must carry near-total feed during flush. Size for the flush flow not just production flow.

Pumps, Metering & Instrumentation

- Feed pump: capable of production und flush flow; verify NPSH and VFD turndown.

- Flowmeters: must read max flush flow; per-stage meters are ideal for balancing.

- Sensors: ΔP by stage, turbidity/SDI, temperature; interlocks for max flush pressure (0.4 MPa) and low flow (blocked valves).

- Materialien: PVC-C/PP/FRP/PTFE for chemical compatibility; avoid dead legs and blind tees.

Automation — PLC Recipes & Safety Interlocks

- One-touch Spülen recipe per stage with timers + pressure caps.

- Permissives: dechlorination OK, tank levels OK, valves in expected position.

- Alarms: high flush pressure, valve disagreement, low flush flow, pump cavitation.

- Data logging: ΔP before/after each flush; trend to optimize frequency and duration.

Water Quality & Pretreatment Considerations

- Bevorzugt permeate flush; if using filtered feed, ensure low SDI/NTU and verified dechlorination.

- Maintain coagulation/backwash stability upstream; dirty filters waste flush water and time.

- Check temperature and viscosity effects—adjust flow targets if needed.

Expected Run-Length Benefit & When to Escalate to CIP

- With a robust RO operational flush program, ΔP rise slows and CIP frequency drops (often by 30–50%).

- Escalate to chemical CIP when flush no longer recovers normalized flux/ΔP to within site thresholds, or when biofouling indicators persist.

Design Checklist (Engineering Review)

- Pipe sizes and valve Cv sized for flush flow; concentrate drain capacity adequate.

- Bypasses and injection quills; pressure relief set to protect elements.

- VFD ramp rates; minimum/maximum flush times per stage; PLC step confirmation.

- Commissioning: verify per-stage flow at ≤0.4 MPa; record valve positions and timings.

Visuals & Downloadables

Related Guides & Tools

Request a Staged-Flush SOP

Send us your stage flows, ΔP trends, and piping/valve list. We’ll return a tailored staged-flush SOP with setpoints, valve matrix, and PLC logic that fits your membrane vendor limits.

About the Author

Stark Water — Process engineers specialized in RO/NF design and O&M. We help plants implement RO operational flush, optimize pretreatment, and reduce CIP frequency safely.

For general water treatment monitoring practices, see the U.S. EPA water research und die WHO water quality resources.

FAQs — RO Operational Flush

1) What’s the difference between operational flush and rinse/CIP?

Operational flush is a short, low-pressure, high-flow sweep to remove loose foulants; rinse only displaces chemicals; CIP uses chemicals when flushing no longer restores performance.

2) Why must flush be low pressure and high flow?

High flow creates shear to remove deposits; low pressure avoids compressing foulants into the surface and keeps membrane stress low.

3) How long and how often should I flush?

Typically 3–10 minutes per stage, once per day. Increase frequency on SDI/NTU spikes, fast ΔP rise, or long stand-by.

4) Can I flush the whole train at once?

Staged flushing is safer for long trains: it prevents re-deposition into later stages and respects pressure caps.

5) Which water should I use for flushing?

Permeate is best. Filtered feed is acceptable if dechlorinated and SDI/NTU is low.

6) What valve/pipe sizes ensure adequate flush flow?

Size concentrate line and valves for the full flush flow per stage (e.g., up to 10.9–12.1 m³/h per 8″ vessel; 2.7 m³/h for 4″).

7) What are safe pressure caps during flush?

Keep feed pressure as low as practicable and ≤ 0.4 MPa unless your vendor allows otherwise.

8) When should I escalate to chemical CIP?

When a flush no longer recovers normalized flux/ΔP to site thresholds or biofouling persists despite increased frequency.