Last updated: November 11, 2025 · Reading time: 12–16 minutes · Audience: plant engineers, EPCs, utility managers

This practical comparison explains the real-world differences between Umkehrosmose (RO), nanofiltration (NF) und ultrafiltration (UF)—from separation scale and salt/organic rejection to operating pressure, pretreatment, and costs. Use the quick selection framework to pick RO vs NF vs UF for your water treatment train.

Executive Summary — Which Membrane Does What?

- UF (Ultrafiltration): removes suspended solids, bacteria, protozoa and high-MW organics; lets dissolved salts pass. Typical pressure ~1–7 bar. Often used as a pretreatment barrier.

- NF (Nanofiltration): partial desalting with preference for divalent ions (hardness) and color/large organics; nominal MWCO ~200–800 Da; typical pressure ~3.5–30 bar.

- RO (Reverse Osmosis): highest desalting; rejects most salts and organics >~100 MW; brackish water and seawater desalination; typical pressure ~8–20 bar (brackish), ~55–80 bar (SWRO).

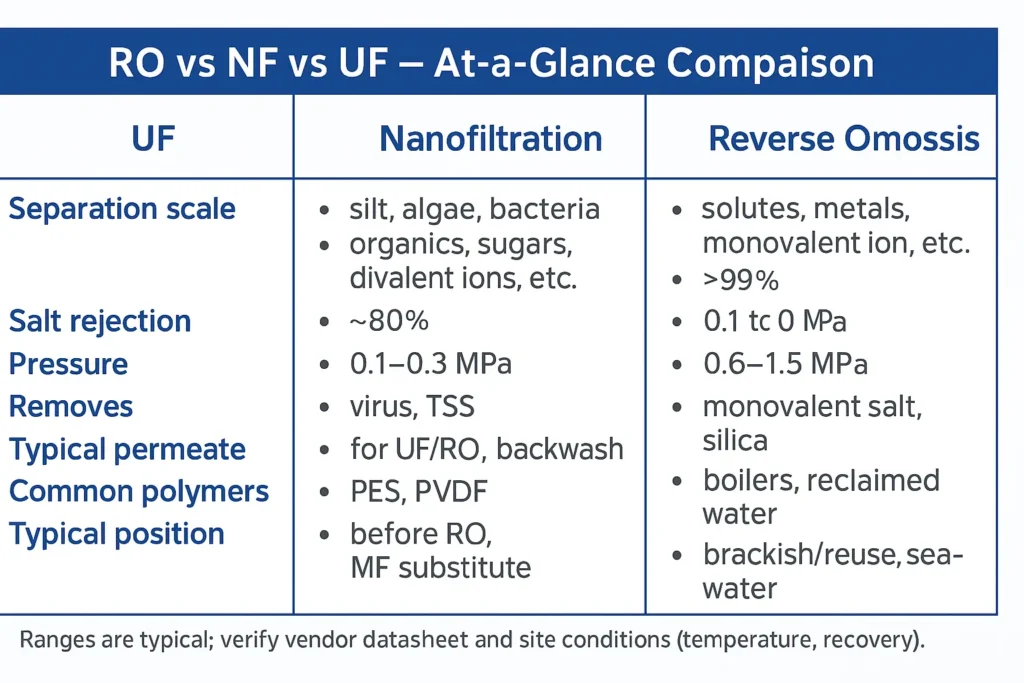

RO vs NF vs UF — At-a-Glance Comparison

| Process | Separation scale | Zurückweisung von Salz | Betriebsdruck | Removes reliably | Typical permeate | Common polymers | Typical position |

|---|---|---|---|---|---|---|---|

| UF | Pores ~0.01–0.1 μm; MWCO ~100–500 kDa | ~0% (salts pass) | ~1–7 bar | Turbidity/SDI, colloids, bacteria, protozoa, high-MW organics | Low turbidity; microbes removed; TDS unchanged | PVDF, PES, PTFE | Pretreatment barrier before NF/RO or as standalone clarity step |

| NF | Nominal MWCO ~200–800 Da | ~20–98% (divalent > monovalent) | ~3.5–30 bar | Hardness (Ca/Mg), color, large organics, partial TDS | Softened/partially desalted water | Thin-film polyamide | After UF; sometimes alternative to softening before RO |

| RO | Non-porous polyamide (molecular-level separation) | High (often >95–99.7%) | ~8–20 bar (BWRO); ~55–80 bar (SWRO) | Most salts, organics, silica (partly), microorganisms | Low-TDS, high-purity water | Thin-film polyamide | Final desalting/polishing after UF (and sometimes NF) |

Values are typical. Operating limits depend on module model, feedwater, temperature, and recovery.

Selection Framework — Start From Your Goal

- Clarity/microbiological barrier: choose UF to meet turbidity/SDI targets or as a robust pretreatment before NF/RO.

- Softening + color/organics control with moderate TDS cut: choose NF.

- Low-TDS/high-purity or seawater desalination: choose RO.

Pretreatment & Acceptance Guidelines

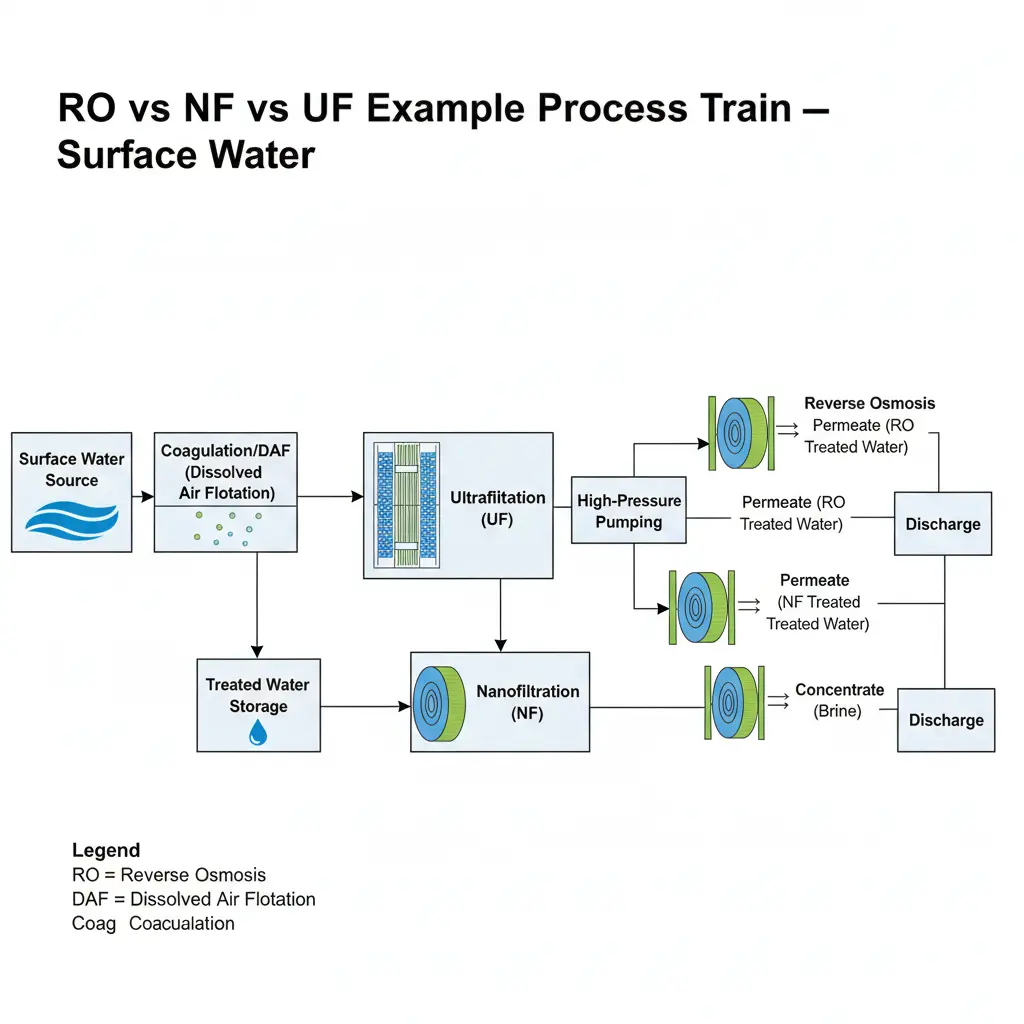

- UF feed controls: screen or strain; coagulant/DAF if needed; backwash and CEB plan; watch NTU/TSS/SDI, oil, Fe/Mn.

- NF/RO feed controls: cartridge filters (5–1 μm), SDI < 3 (typical), low turbidity, no free chlorine on polyamide, antiscalant or softening per saturation indices.

- Acceptance checks: normalized TMP/flux (UF), normalized salt rejection & ΔP (NF/RO); trend vs temperature.

Operations & Cost Levers

- Pressure/Energy: UF ≪ NF < RO. Optimize flux and recoveries; use VFDs and ULP membranes where applicable.

- Recovery & concentrate: NF/RO require scaling control (antiscalant/softening/acid). UF has backwash/CEB/CIP cycles.

- Cleaning chemistry: UF often acid/alkali/oxidant within polymer limits; NF/RO typically alkaline for organics, acid for inorganics—respect vendor pH, temperature and free-chlorine limits.

- Monitoring: log TMP, flux, ΔP by stage, conductivity/salt rejection, SDI/NTU and temperature; normalize data for diagnosis.

Application Playbook

- UF: surface water pretreatment to RO; tertiary reuse turbidity barrier; beverage clarification.

- NF: hardness removal and color reduction; partial desalting for industrial processes; pre-RO softening to reduce scaling.

- RO: brackish & seawater desalination; high-purity process water; reuse polishing; boiler/DI feed.

Example Process Trains

References & Further Reading

- U.S. EPA — Water Research

- WHO — Water Quality & Health Guidelines

- ISO 20468 — Guidelines for Performance Evaluation of Treatment Technologies

- AWWA Manuals — Membrane Processes (UF/NF/RO)

Need Help Choosing RO vs NF vs UF?

Send your feed analysis (TDS, hardness, color, TOC/UV254, SDI/NTU) and production target—we’ll map a membrane train, estimate energy & recovery, and provide a quote.

Water Treatment Solutions - Case Studies - Blog - Stark Water Tools - Angebot anfordern

About the Author

Stark Water — Process engineers specialized in membrane diagnostics (UF/NF/RO), pretreatment, and lifecycle-cost optimization.

FAQs — RO vs NF vs UF

1) Is NF just a “weaker RO”?

No. NF is designed for selective removal—especially hardness (divalent ions), color and large organics—at lower pressure than RO.

2) When can UF alone meet my spec?

When your goal is turbidity/microbiological control without desalting, e.g., pretreatment, reuse barrier, beverage clarification.

3) Can NF replace ion-exchange softening?

Frequently, yes—NF removes Ca/Mg hardness and color, often with less chemical handling than lime/IX, but verify alkalinity/scaling.

4) What pressures should I plan for?

UF ~1–7 bar; NF ~3.5–30 bar; RO ~8–20 bar (brackish) and ~55–80 bar (SWRO). Exact numbers depend on model, temperature and recovery.

5) How do I prevent NF/RO fouling and scaling?

Control SDI/turbidity via UF; remove oxidants for polyamide; dose antiscalant or soften; keep logs and normalize performance.