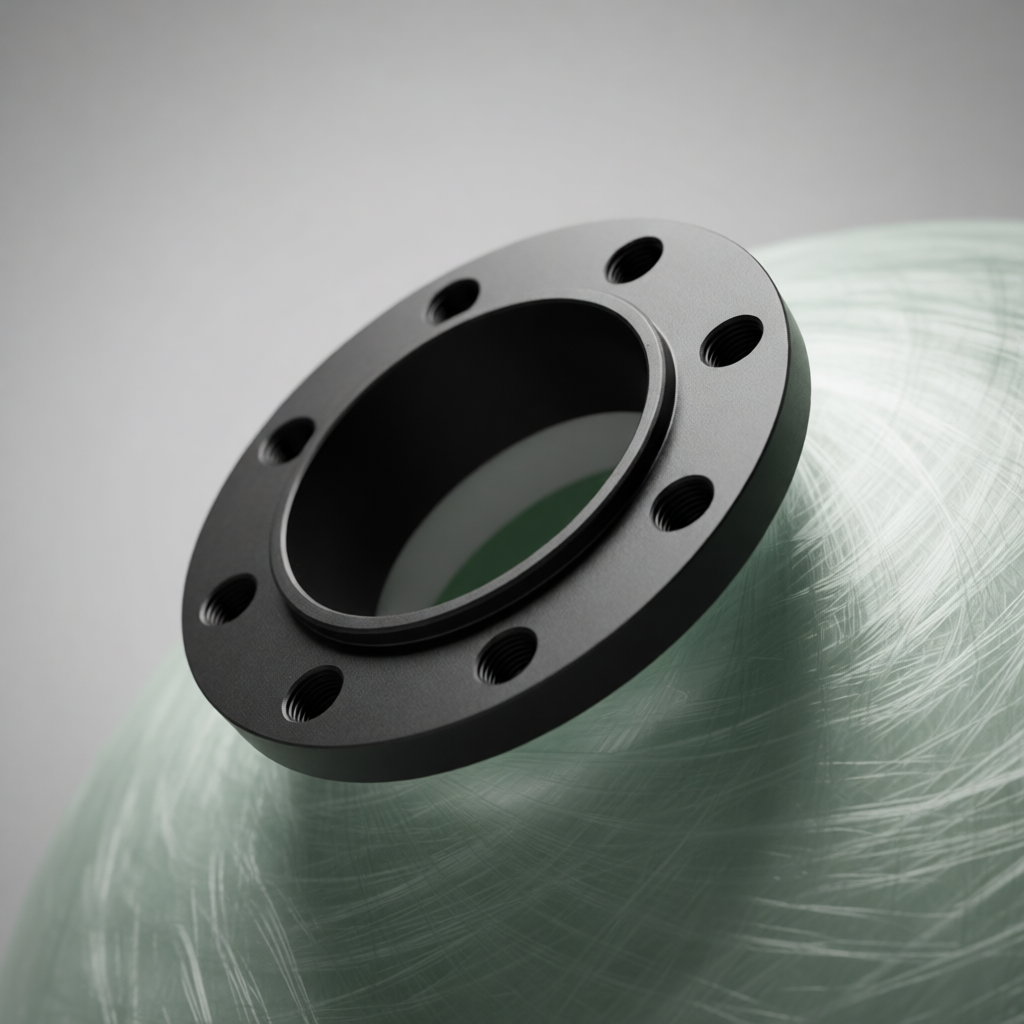

Stark Industrial 6″ Flange Pressure Vessel Series (Heavy Duty)

The Stark industrial **6″ Flange pressure vessel** is engineered for high-volume filtration applications. Featuring a secure 6-inch flange top opening, this heavy-duty tank series (36″-72″ diameter) is designed for municipal water treatment and large-scale industrial plants requiring maximum flow rates and absolutely leak-proof pipe connections.

Beschreibung des Produkts

Engineered for the Toughest Industrial Demands.

The Stark **6″ Flange pressure vessel** series represents the pinnacle of large-scale composite manufacturing. Unlike threaded connections which can be prone to leaks under the stress of large piping systems, our 6-inch flange interface offers a robust, bolted connection point compatible with standard DN150 industrial piping. This ensures zero-leakage performance even under high vibration or pressure surges common in desalination plants and municipal facilities.

Our proprietary multi-axis winding process ensures that even our largest 72-inch vessels maintain structural rigidity and uniform pressure distribution, offering a superior, corrosion-resistant alternative to rubber-lined steel tanks.

Installation & Standard Data:

Proper flange alignment and bolt torque are critical for large vessel safety. For detailed flange dimension drawings (ANSI/DIN), bolt circle specifications, and installation torque guides, please reference the technical documentation at our specialized manufacturing division:

Stark Tank Manufacturing – 6″ Flange Series Technical Specs

.

Produkt-Parameter

Below are the verified specifications for our 6″ Flange top-mount series. These heavy-duty tanks are designed for industrial applications requiring high flow rates.

| Modell | Volume Capacity | Dimensions (Dia x H) | Flow Rate (m³/h) | B2B Quote | ||

|---|---|---|---|---|---|---|

| Typ | US Gal | Liters | Nominal | mm | (Filter/Softener) | Action |

| STK-3694 | 318.4 | 1205 | 36″ x 94″ | Ø900 x 2465 | 7.6-10 / 12-19 | Inquiry |

| STK-4094 | 351.9 | 1332 | 40″ x 94″ | Ø1000 x 2430 | 9.4-11.7 / 15.7-23.5 | Inquiry |

| STK-4272 | 290.6 | 1100 | 42″ x 72″ | Ø1080 x 1850 | 15-25 / 26-30 | Inquiry |

| STK-4872 | 345.6 | 1308 | 48″ x 72″ | Ø1200 x 1880 | 13.5-17 / 22.6-34 | Inquiry |

| STK-4894 | 504.4 | 1909 | 48″ x 94″ | Ø1200 x 2430 | 13.5-17 / 22.6-34 | Inquiry |

| STK-6083 | 570.1 | 2158 | 60″ x 83″ | Ø1500 x 2120 | 21-27 / 35-53 | Inquiry |

| STK-6094 | 710.2 | 2688 | 60″ x 94″ | Ø1500 x 2430 | 21-27 / 35-53 | Inquiry |

| STK-6383 | 681.6 | 2580 | 63″ x 83″ | Ø1600 x 2100 | 25-45 / 46-56 | Inquiry |

| STK-7294 | 940.8 | 3561 | 72″ x 94″ | Ø1800 x 2400 | 30-40 / 50-76 | Inquiry |

*Note: US dimensions are nominal. Flow rates are for reference only. Please consult our engineers for precise system design.

Anwendbare Industrie

- Municipal Water Treatment:

Large-scale sand and carbon filtration for city water supplies, removing sediment and contaminants at high throughput. - Meerwasserentsalzung:

Pre-treatment filtration for SWRO plants, utilizing corrosion-resistant FRP to withstand aggressive saline environments. - Power Plant Cooling Systems:

Side-stream filtration for cooling towers to reduce suspended solids and prevent heat exchanger fouling.

Vorteil Eins

Secure Flange Connection

For vessels exceeding 36 inches in diameter, threaded connections are often insufficient. Stark’s 6-inch flange top opening provides a standardized, bolted connection that eliminates the risk of thread stripping or cross-threading during installation.This design allows for the secure attachment of heavy industrial piping (steel or large diameter UPVC) and ensures a reliable seal capable of withstanding system vibration and hydraulic shock.Vorteil ZWEI

Massive Capacity, Minimal Maintenance

With diameters up to 72 inches, these vessels hold thousands of liters of media, allowing for extended service runs between backwashes. Unlike traditional rubber-lined steel tanks, Stark FRP vessels are inherently rust-proof and require zero painting or lining maintenance.This significantly reduces the total cost of ownership (TCO) for large-scale projects while providing a service life that often exceeds 10 years in harsh conditions.Verwandte Produkte

Ähnliche Produkte

- Zubehör für die Wasseraufbereitung

5-Mikron-20-Zoll-PP-Filter (schmelzgeblasenes Sediment) | STARK

Weiterlesen

FAQ

F1: Wie lange hält die Umkehrosmoseanlage?

Die Lebensdauer einer Umkehrosmoseanlage hängt von der Wasserqualität und der Wartung ab. In der Regel hält die Membran 2-3 Jahre, während das System selbst bei richtiger Pflege über 10 Jahre halten kann.

F2: Kann das System an die unterschiedlichen Wasserbedingungen angepasst werden?

Ja, alle unsere Systeme sind vollständig anpassbar. Wir analysieren Ihren Wasserbericht und Ihren Anwendungsbedarf, bevor wir maßgeschneiderte Lösungen anbieten.

F3: Welche Normen erfüllen die STARK Geräte?

Unsere Produkte sind CE- und ISO 9001-konform und können auf Wunsch so gestaltet werden, dass sie spezifischen regionalen Vorschriften oder Industrienormen entsprechen.

F4: Wie lange ist die Lieferzeit für STARK RO Systeme?

Standardsysteme werden innerhalb von 7-15 Tagen ausgeliefert. Bei kundenspezifischen Aufträgen kann sich die Lieferzeit je nach Komplexität auf 20-25 Tage verlängern.

F5: Bieten Sie technische Unterstützung oder Installationshilfen an?

Ja. Wir bieten eine vollständige technische Dokumentation, eine Fernanleitung per Video und können auf Wunsch Techniker ins Ausland schicken.

F6: Was ist in Ihrem Angebot enthalten?

Unser Angebot umfasst die komplette Umkehrosmoseanlage, die Schalttafel, die Pumpen, die Vorbehandlungseinheiten und alle erforderlichen Armaturen. Installationswerkzeuge und Ersatzteile können auf Anfrage mitgeliefert werden.