FRP Pressure Vessels – 2.5″ NPSM Series for Water Treatment

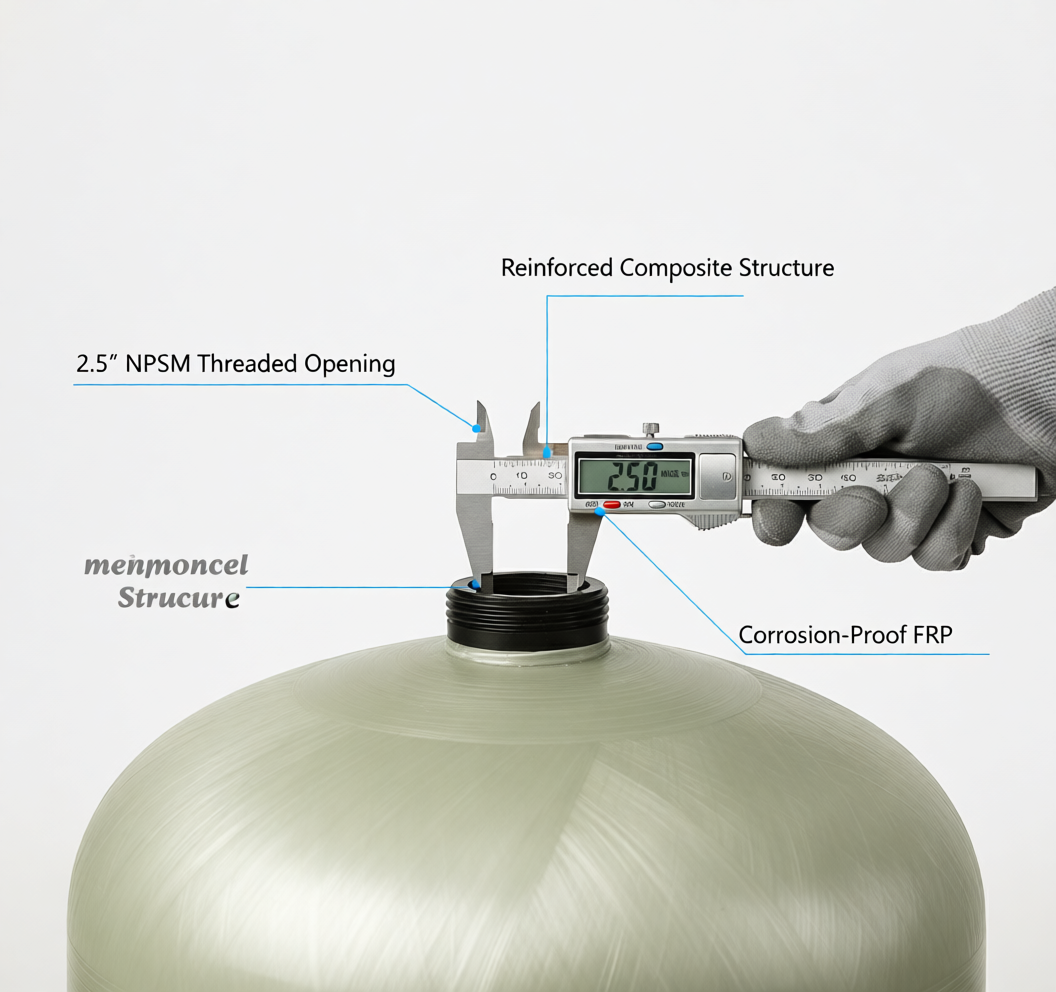

High-performance FRP pressure vessel featuring a standard 2.5″ NPSM threaded opening. Designed for residential and light commercial water treatment, this tank is universally compatible with Runxin, Fleck, and Clack control valves, making it the ideal housing for water softeners, carbon filters, and RO pre-treatment systems.

Beschreibung des Produkts

The Backbone of Efficient Water Filtration Systems.

The Stark 2.5″ NPSM Series is our most versatile line of composite fiberglass pressure vessels. Unlike traditional steel tanks that are prone to rust and heavy to handle, our composite vessels feature a seamless high-density polyethylene (HDPE) inner liner wound with continuous fiberglass strands and sealed with high-grade epoxy resin.

This advanced construction ensures 100% corrosion-free performance and zero contamination, making it perfect for drinking water applications and critical RO pre-treatment stages.

Technical Note:

Our tanks undergo rigorous burst pressure and fatigue testing. For detailed structural stress analysis, raw material composition, or specific manufacturing protocols, please reference the official technical data at our specialized manufacturing division:

Stark Tank Manufacturing – 2.5″ NPSM Series Specs

Produkt-Parameter

Use the chart below to select the correct vessel size based on your required resin volume or flow rate.

| Modell | Volume Capacity | Dimensions (Dia x H) | Flow Rate (m³/h) | B2B Quote | ||

|---|---|---|---|---|---|---|

| Typ | US Gal | Liters | Inch | mm | Referenz | Action |

| STK-713 | 1.6 | 6 | 7″ x 13″ | Ø180 x 335 | 0.3-0.7 | Inquiry |

| STK-717 | 2.4 | 9 | 7″ x 17″ | Ø180 x 430 | 0.3-0.7 | Inquiry |

| STK-735 | 5.3 | 20 | 7″ x 35″ | Ø180 x 905 | 0.3-0.7 | Inquiry |

| STK-817 | 2.9 | 11 | 8″ x 17″ | Ø205 x 445 | 0.3-0.7 | Inquiry |

| STK-835 | 6.3 | 24 | 8″ x 35″ | Ø205 x 905 | 0.3-0.7 | Inquiry |

| STK-844 | 8.7 | 33 | 8″ x 44″ | Ø205 x 1130 | 0.3-0.7 | Inquiry |

| STK-935 | 8.7 | 33 | 9″ x 35″ | Ø230 x 905 | 0.5-1.2 | Inquiry |

| STK-942 | 10.3 | 39 | 9″ x 42″ | Ø230 x 1085 | 0.5-1.2 | Inquiry |

| STK-948 | 11.9 | 45 | 9″ x 48″ | Ø230 x 1230 | 0.5-1.2 | Inquiry |

| STK-1017 | 4.8 | 18 | 10″ x 17″ | Ø255 x 445 | 0.8-1.4 | Inquiry |

| STK-1035 | 10.3 | 39 | 10″ x 35″ | Ø255 x 905 | 0.8-1.4 | Inquiry |

| STK-1044 | 12.9 | 49 | 10″ x 44″ | Ø255 x 1130 | 0.8-1.4 | Inquiry |

| STK-1054 | 16.4 | 62 | 10″ x 54″ | Ø255 x 1390 | 0.8-1.4 | Inquiry |

| STK-1252 | 22.5 | 85 | 12″ x 52″ | Ø300 x 1340 | 0.8-1.5 | Inquiry |

| STK-1265 | 28.0 | 106 | 12″ x 65″ | Ø300 x 1650 | 0.8-1.5 | Inquiry |

| STK-1354 | 27.5 | 104 | 13″ x 54″ | Ø330 x 1400 | 1.2-2.3 | Inquiry |

| STK-1665 | 49.7 | 188 | 16″ x 65″ | Ø400 x 1670 | 1.2-2.3 | Inquiry |

*Flow rates are for reference only. Please consult our engineers for specific system design parameters.

Anwendbare Industrie

- Water Softening Systems:

Ideal housing for cation exchange resin to remove calcium and magnesium hardness in residential and industrial boiler feed water. - Activated Carbon Filtration:

Used for de-chlorination, organics removal, and taste/odor improvement in municipal water supply lines. - RO Pre-Treatment:

Acts as the primary sand/multimedia filter to protect sensitive Reverse Osmosis membranes from sediment and particulate fouling.

Vorteil Eins

Corrosion-Resistant Composite Construction

Stark FRP vessels are engineered to outlast traditional steel tanks in aggressive water environments. The inner shell is molded from seamless, food-grade High-Density Polyethylene (HDPE), ensuring that water never touches metal. This guarantees zero rust and no heavy metal leaching.The outer shell is reinforced with continuous strands of fiberglass embedded in high-performance epoxy resin, providing a pressure rating of 150 PSI (10.5 Bar) while being 60% lighter than steel equivalents.Vorteil ZWEI

Universal Compatibility & Easy Maintenance

Designed with the system integrator in mind, the 2.5″ NPSM threaded top opening is manufactured with precision tolerances to ensure a leak-free seal with all major control valve brands, including Runxin, Fleck, Clack, and Autotrol.The lightweight composite structure simplifies transport and installation, allowing a single technician to position the tank and load media (Resin, Carbon, or Sand) without the need for heavy lifting equipment.Verwandte Produkte

Ähnliche Produkte

- Zubehör für die Wasseraufbereitung

Durchflussmesser aus Kunststoff und Acryl (Rotameter) | Stark Water

Weiterlesen

FAQ

F1: Wie lange hält die Umkehrosmoseanlage?

Die Lebensdauer einer Umkehrosmoseanlage hängt von der Wasserqualität und der Wartung ab. In der Regel hält die Membran 2-3 Jahre, während das System selbst bei richtiger Pflege über 10 Jahre halten kann.

F2: Kann das System an die unterschiedlichen Wasserbedingungen angepasst werden?

Ja, alle unsere Systeme sind vollständig anpassbar. Wir analysieren Ihren Wasserbericht und Ihren Anwendungsbedarf, bevor wir maßgeschneiderte Lösungen anbieten.

F3: Welche Normen erfüllen die STARK Geräte?

Unsere Produkte sind CE- und ISO 9001-konform und können auf Wunsch so gestaltet werden, dass sie spezifischen regionalen Vorschriften oder Industrienormen entsprechen.

F4: Wie lange ist die Lieferzeit für STARK RO Systeme?

Standardsysteme werden innerhalb von 7-15 Tagen ausgeliefert. Bei kundenspezifischen Aufträgen kann sich die Lieferzeit je nach Komplexität auf 20-25 Tage verlängern.

F5: Bieten Sie technische Unterstützung oder Installationshilfen an?

Ja. Wir bieten eine vollständige technische Dokumentation, eine Fernanleitung per Video und können auf Wunsch Techniker ins Ausland schicken.

F6: Was ist in Ihrem Angebot enthalten?

Unser Angebot umfasst die komplette Umkehrosmoseanlage, die Schalttafel, die Pumpen, die Vorbehandlungseinheiten und alle erforderlichen Armaturen. Installationswerkzeuge und Ersatzteile können auf Anfrage mitgeliefert werden.