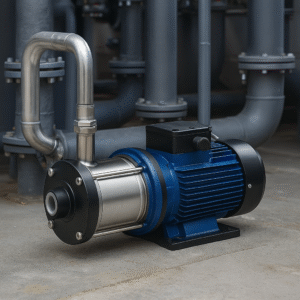

STARK Unterwasserpumpe Tiefbrunnenwasserpumpe

Efficiently extract water from deep sources with Stark Water’s STARK Submersible Pump. This robust submersible pump is specifically designed as a deep well water pump, providing reliable and energy-efficient water supply for residential, agricultural, municipal, and industrial applications.

Beschreibung des Produkts

Accessing water from deep underground sources, such as wells and boreholes, presents unique challenges that conventional surface pumps cannot effectively address. The Stark Water STARK Submersible Pump is expertly engineered to overcome these obstacles, providing a reliable, efficient, and long-lasting solution for drawing water from significant depths. This pump represents the pinnacle of deep well water extraction technology, ensuring a consistent supply for various demanding applications.

The Unrivaled Efficiency of a Submersible Pump for Deep Wells

The defining characteristic of a submersible pump is its ability to operate completely immersed in the water it pumps. Unlike jet pumps or other surface pumps that pull water, a submersible pump pushes water upwards, a far more energy-efficient method for deep wells. This inherent design offers several key advantages:

- High Efficiency: By pushing water, it avoids the energy losses associated with suction lift, resulting in significantly higher hydraulic efficiency and lower power consumption for a given flow and head.

- Quiet Operation: Since the motor is submerged, it operates virtually silently, making it ideal for residential areas or applications where noise pollution is a concern.

- No Priming Required: As it’s always submerged, there’s no need to prime the pump, simplifying startup and preventing issues related to airlocks.

- Less Susceptible to Cavitation: Operating below the water level inherently reduces the risk of cavitation, which can damage pumps.

Our STARK Submersible Pump is specifically designed as a deep well water pump, optimized for narrow boreholes and capable of handling high heads to deliver water from profound depths with remarkable reliability.

Robust Construction and Reliability in Challenging Conditions

Durability and reliability are paramount for pumps operating deep underground, where access for maintenance can be challenging. The STARK Submersible Pump is built with robust, corrosion-resistant materials, typically high-grade stainless steel (SUS304 or SUS316) for the casing, impeller, and shaft. The motor is hermetically sealed and often water or oil-filled to protect it from water ingress and provide efficient cooling. This rugged construction ensures a long operational lifespan and consistent performance even in challenging well conditions, including those with abrasive sand content (within limits) or corrosive groundwater chemistry. Integrated protection features, such as thermal overload protection and dry-run sensors, further enhance its reliability and prevent costly damage, making it a dependable long-term investment for continuous water supply.

Versatile Applications for Deep Well Water Pump Needs

The STARK Submersible Pump, as a dedicated deep well water pump, is a versatile solution for a broad spectrum of water supply needs where groundwater is the primary source. From providing clean drinking water to extensive irrigation and industrial supply, its high-head capability and robust design make it an ideal choice for various demanding applications. It ensures a constant and stable water flow, even from deep aquifers, contributing to the sustainability and efficiency of your water management system.

Produkt-Parameter

The Stark Water STARK Submersible Pump is engineered for efficient and reliable deep well water extraction. Here are its key technical specifications:

| Parameter | Spezifikation / Anpassungsoptionen |

|---|---|

| Hauptschlüsselwort Fokus | submersible pump design and capabilities. |

| Pumpen-Typ | Submersible Centrifugal Pump (Multistage for deep wells). |

| Anwendungsschwerpunkt | Deep Well Water Pump, Borehole Pump, Groundwater Extraction. |

| Available Diameters | Standard sizes: 4-inch, 6-inch, 8-inch, 10-inch, 12-inch, etc., to fit various well casings. |

| Baumaterial | Pump Casing: Stainless Steel (SUS304, SUS316). Impeller/Diffuser: Stainless Steel, Noryl, or Cast Iron. Shaft: Stainless Steel. Motor Housing: Stainless Steel. |

| Motorleistung | Varies by model and required head/flow (e.g., 0.37 kW to 200 kW or higher). |

| Spannung und Frequenz | Single Phase 220V/50Hz or Three Phase 380V/50Hz (customizable for 60Hz/other voltages). |

| Flow Rate (Q) | Varies by model (e.g., 1 m³/hr to 500+ m³/hr / 4.4 GPM to 2200+ GPM). |

| Max. Head (H) | Varies significantly by model (e.g., 10m to 600m or more), designed for deep well lifting. |

| Max. Betriebstemperatur | Typically 30°C (86°F) for standard models; higher temperature versions available. |

| Max. Sand Content | Usually 50 g/m³ (0.05%), specialized versions for higher sand content available. |

| Motor Cooling Type | Water-filled or Oil-filled (depending on motor type). |

| Protection Features | Built-in thermal overload protection, optional dry-run protection, soft starters for larger motors. |

| Verbindungstyp | Threaded or Flanged discharge connections. |

| Isolationsklasse | F. |

| Schutzklasse | IP68 (for continuous submersion). |

Anwendbare Industrie

The Stark Water STARK Submersible Pump, as a powerful deep well water pump, is a versatile and essential solution for reliable water extraction from underground sources across a broad spectrum of industrial, commercial, and residential applications. Its robust design makes it ideal for:

- Residential Water Supply: Providing a dependable source of clean drinking water for homes and properties relying on private wells or boreholes.

- Agricultural Irrigation: Essential for drawing water from deep wells to irrigate crops, vineyards, orchards, and livestock farms, particularly in regions with limited surface water.

- Municipal Water Supply: Used in boreholes and deep wells to supplement or provide the primary water source for towns, cities, and rural communities.

- Industrial Water Supply: Supplying groundwater for various industrial processes, manufacturing operations, cooling systems, and general utility within factories and industrial parks.

- Mining & Dewatering: For dewatering operations in mines, quarries, and construction sites where water needs to be pumped from deep excavations or sumps.

- Commercial & Institutional Buildings: Providing water supply for hotels, resorts, schools, and hospitals that utilize deep well sources.

- Groundwater Remediation: Used in environmental projects for pumping contaminated groundwater for treatment.

- Aquaculture: Supplying water from deep wells for fish farms and aquaculture operations, ensuring a consistent water quality.

- Geothermal Systems: Circulating water in certain ground-source heat pump systems.

Vorteil Eins

Vorteil ZWEI

Verwandte Produkte

Ähnliche Produkte

FAQ

F1: Wie lange hält die Umkehrosmoseanlage?

Die Lebensdauer einer Umkehrosmoseanlage hängt von der Wasserqualität und der Wartung ab. In der Regel hält die Membran 2-3 Jahre, während das System selbst bei richtiger Pflege über 10 Jahre halten kann.

F2: Kann das System an die unterschiedlichen Wasserbedingungen angepasst werden?

Ja, alle unsere Systeme sind vollständig anpassbar. Wir analysieren Ihren Wasserbericht und Ihren Anwendungsbedarf, bevor wir maßgeschneiderte Lösungen anbieten.

F3: Welche Normen erfüllen die STARK Geräte?

Unsere Produkte sind CE- und ISO 9001-konform und können auf Wunsch so gestaltet werden, dass sie spezifischen regionalen Vorschriften oder Industrienormen entsprechen.

F4: Wie lange ist die Lieferzeit für STARK RO Systeme?

Standardsysteme werden innerhalb von 7-15 Tagen ausgeliefert. Bei kundenspezifischen Aufträgen kann sich die Lieferzeit je nach Komplexität auf 20-25 Tage verlängern.

F5: Bieten Sie technische Unterstützung oder Installationshilfen an?

Ja. Wir bieten eine vollständige technische Dokumentation, eine Fernanleitung per Video und können auf Wunsch Techniker ins Ausland schicken.

F6: Was ist in Ihrem Angebot enthalten?

Unser Angebot umfasst die komplette Umkehrosmoseanlage, die Schalttafel, die Pumpen, die Vorbehandlungseinheiten und alle erforderlichen Armaturen. Installationswerkzeuge und Ersatzteile können auf Anfrage mitgeliefert werden.