Sistema de tratamiento de agua por ósmosis inversa 500L/H | STARK Water

Get reliable pure water for your business with the Stark Water 500L/H Reverse Osmosis Water Treatment System. This compact and efficient RO system delivers 500 liters of purified water per hour, making it ideal for small to medium-sized commercial, industrial, and laboratory applications requiring consistent high-quality water.

Descripción del producto

For many small to medium-sized enterprises, laboratories, and specialized commercial operations, a consistent supply of high-purity water is essential, yet large-scale systems can be overkill. The Stark Water 500L/H Reverse Osmosis Water Treatment System is meticulously designed to meet this precise need, offering a compact, efficient, and highly reliable solution for producing up to 500 liters of purified water per hour.

Optimized Purification for Diverse Applications

At the core of this system is advanced **Reverse Osmosis (RO) technology**, renowned for its ability to effectively remove up to 99% of dissolved solids, salts, heavy metals, organic compounds, bacteria, and viruses from raw water sources. This level of purification is critical for applications where water quality directly impacts product integrity, experimental accuracy, equipment longevity, or human health.

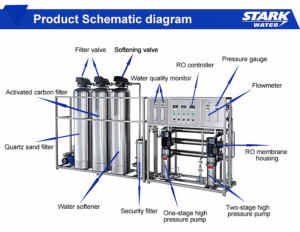

Our 500L/H RO system incorporates a multi-stage filtration process to ensure optimal performance and membrane protection:

- Pre-filtration: Incoming water first passes through robust pre-filters, typically including multi-media filtration (like sand and activated carbon) to eliminate larger suspended solids, chlorine, and organic matter. This crucial step safeguards the sensitive RO membranes from premature fouling.

- Fine Filtration: Subsequent micron cartridge filters (e.g., 5-micron or 1-micron) capture any remaining fine particulates, preparing the water for the RO stage.

- High-Pressure RO Membrane Filtration: A high-pressure pump forces the pre-treated water through specialized semi-permeable RO membranes, separating pure water from concentrated impurities, which are then discharged.

- Tratamiento posterior (opcional): For specific ultra-pure water requirements, additional modules like UV sterilization or deionization can be seamlessly integrated.

This comprehensive approach ensures consistently high-quality purified water, making it a dependable backbone for your water-dependent processes.

Compact Design, Robust Build, and User-Friendly Operation

The Stark Water 500L/H RO system is engineered with space efficiency in mind. Its compact footprint makes it an ideal fit for laboratories, small factories, clinics, and commercial kitchens where space is often at a premium. Despite its smaller size, the system doesn’t compromise on durability. It features robust construction, often utilizing a high-quality stainless steel frame and reliable components, ensuring a long operational lifespan and resistance to corrosive environments.

Ease of use is another key advantage. The integrated control panel provides automated operation, real-time monitoring of critical parameters (like pressure and water quality via a TDS meter), and built-in safety features such as low-pressure protection and automatic flushing cycles. This automation simplifies daily operations, reduces manual intervention, and ensures consistent performance, allowing your team to focus on their core tasks while the system reliably delivers pure water.

Parámetros del producto

The Stark Water 500L/H Reverse Osmosis Water Treatment System is built for efficient and reliable pure water production. Here are its key technical specifications:

- Capacidad de agua pura: 500 Liters per Hour (LPH) / Approximately 2.2 Gallons per Minute (GPM)

- Fuente de agua bruta: Suitable for municipal tap water, well water, or brackish water (recommended TDS up to 1000-2000 ppm, depending on design).

- Tipo de membrana RO: High-rejection, low-pressure Composite Polyamide RO Membrane (e.g., typically 1-2 x 4040 series membrane).

- Bomba de alta presión: Stainless Steel multistage centrifugal pump, specifically selected for this flow rate.

- Sistema de pretratamiento:

- Multi-Media Filter (e.g., Sand Filter, Activated Carbon Filter) for suspended solids, chlorine, and organic matter removal.

- Precision Cartridge Filter (e.g., 5-micron or 1-micron) for fine particulate removal.

- Opcional: Sistema de dosificación de productos químicos (por ejemplo, antiescalante) basado en el análisis del agua bruta.

- Tasa de rechazo de sal: ≥97% - 99%

- Tasa de recuperación de agua: 50% – 75% (Dependent on raw water quality and system design).

- Calidad del agua de salida: TDS typically <50 ppm (adjustable based on raw water), suitable for various pure water applications.

- Fuente de alimentación: Single-Phase 220V AC, 50Hz/60Hz or 3 Phase 380V AC, 50Hz/60Hz (Customizable as per client region).

- Sistema de control: Automatic control panel with pressure gauges, flow meters, online TDS meter, auto flush, and safety shut-offs (e.g., low/high pressure protection).

- Material de construcción:

- Bastidor: Acero al carbono con recubrimiento de polvo o acero inoxidable (se recomienda SS304).

- Tuberías: UPVC para baja presión, Acero inoxidable (SS304) para alta presión.

- Recipientes a presión: FRP (plástico reforzado con fibra) o acero inoxidable.

- Requisitos de agua de entrada:

- Presión de entrada: 0,2 - 0,4 MPa

- Turbidez: <1,0 NTU

- Cloro: <0,1 ppm

- SDI (Índice de densidad del limo): <5

- Dimensiones (aproximadas): Compact design, typically L 1000mm x W 500mm x H 1400mm.

- Temperatura de funcionamiento: 5°C - 45°C.

Industria aplicable

The Stark Water 500L/H Reverse Osmosis Water Treatment System is a versatile and efficient solution for various small to medium-scale operations requiring consistent access to high-purity water. Its compact design and reliable performance make it ideal for:

- Laboratorios e instalaciones de investigación: Provides purified water for glassware washing, reagent preparation, analytical testing, and general lab use.

- Clinics & Medical Facilities: Supplies high-quality water for sterilization equipment (autoclaves), dental units, dialysis centers (pre-treatment), and general utility.

- Small Bottled Water Plants & Beverage Production: Essential for producing pure drinking water, juices, and soft drinks, ensuring product quality and taste.

- Commercial Kitchens & Restaurants: Delivers pure water for cooking, ice making, coffee machines, and dishwashing, improving taste and protecting appliances.

- Hotels & Guesthouses: Supplies pure water for drinking, ice machines, and general amenities, enhancing guest experience.

- Hydroponics & Specialized Agriculture: Provides precise water quality for nutrient solutions, optimizing plant growth and yield.

- Schools & Educational Institutions: Ensures access to safe, purified drinking water for students and staff.

- Boiler Feed Water (Small Scale): Pre-treatment for small industrial or commercial boilers to prevent scaling and improve efficiency.

- Car Washes & Detailing Shops: Proporciona agua de aclarado sin manchas, mejorando el aspecto del vehículo y la satisfacción del cliente.

Ventaja Uno

Ventaja DOS

Productos relacionados

Productos relacionados

- Sistema de ósmosis inversa

Stark 6000LPH acero inoxidable ssteel tratamiento de agua ósmosis inversa equipo de agua pura

Leer más

PREGUNTAS FRECUENTES

P1: ¿Cuánto dura el sistema de ósmosis inversa?

La vida útil de un sistema de ósmosis inversa depende de la calidad del agua y del mantenimiento. Normalmente, la membrana dura entre 2 y 3 años, mientras que el sistema en sí puede durar más de 10 años con los cuidados adecuados.

P2: ¿Se puede personalizar el sistema en función de las diferentes condiciones del agua?

Sí, todos nuestros sistemas son totalmente personalizables. Analizamos su informe de aguas y sus necesidades de aplicación antes de ofrecerle soluciones a medida.

P3: ¿Qué normas cumplen los equipos STARK?

Nuestros productos cumplen las normas CE e ISO 9001, y pueden diseñarse para cumplir normativas regionales o estándares industriales específicos si así se solicita.

P4: ¿Cuál es el plazo de entrega de los sistemas de ósmosis inversa STARK?

Los sistemas estándar se envían en un plazo de 7-15 días. Para los pedidos personalizados, el plazo de entrega puede prolongarse hasta 20-25 días en función de la complejidad.

P5: ¿Ofrecen asistencia técnica u orientación para la instalación?

Sí. Proporcionamos documentación técnica completa, asistencia remota por vídeo y podemos enviar ingenieros al extranjero si así se solicita.

P6: ¿Qué incluye su presupuesto?

Nuestro presupuesto incluye el sistema de ósmosis inversa completo, el panel de control, las bombas, las unidades de pretratamiento y todos los accesorios necesarios. Si lo desea, podemos incluir herramientas de instalación y piezas de repuesto.