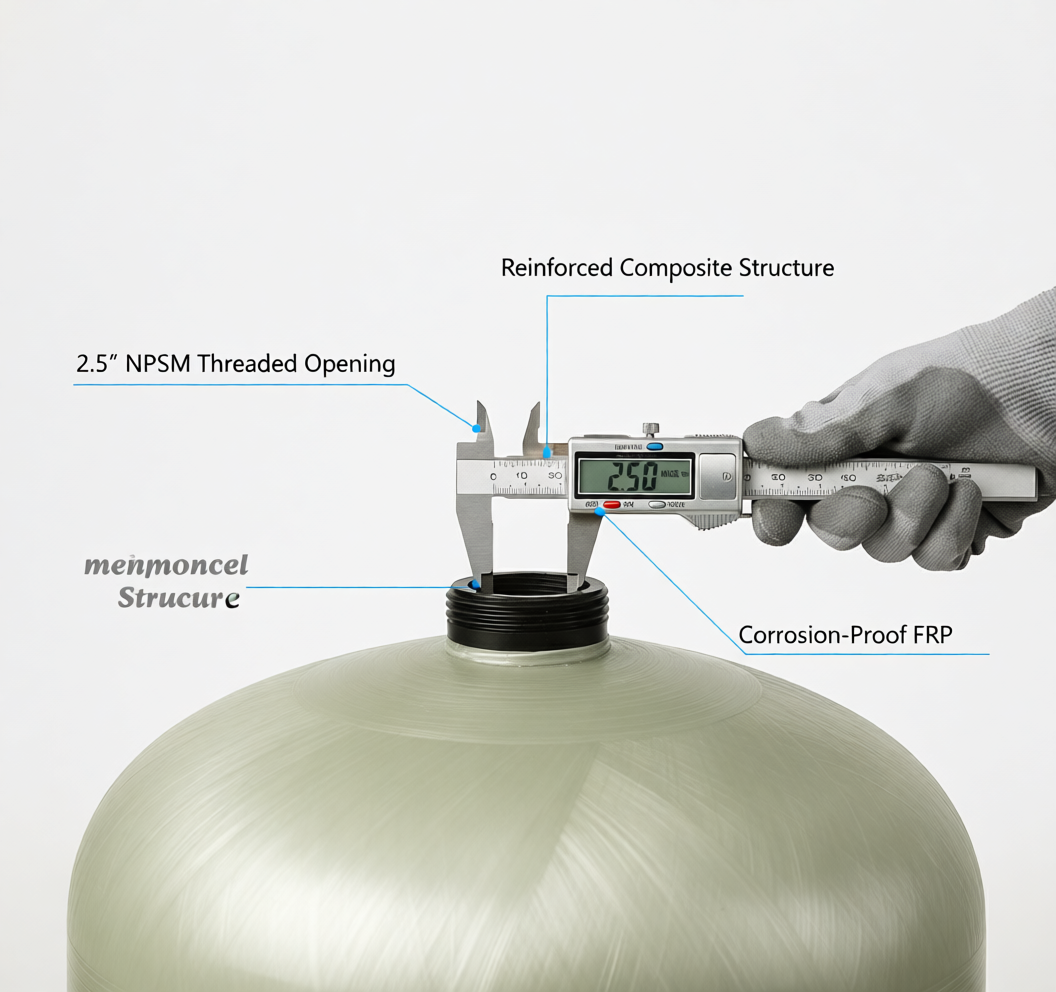

FRP Pressure Vessels – 2.5″ NPSM Series for Water Treatment

High-performance FRP pressure vessel featuring a standard 2.5″ NPSM threaded opening. Designed for residential and light commercial water treatment, this tank is universally compatible with Runxin, Fleck, and Clack control valves, making it the ideal housing for water softeners, carbon filters, and RO pre-treatment systems.

Descripción del producto

The Backbone of Efficient Water Filtration Systems.

The Stark 2.5″ NPSM Series is our most versatile line of composite fiberglass pressure vessels. Unlike traditional steel tanks that are prone to rust and heavy to handle, our composite vessels feature a seamless high-density polyethylene (HDPE) inner liner wound with continuous fiberglass strands and sealed with high-grade epoxy resin.

This advanced construction ensures 100% corrosion-free performance and zero contamination, making it perfect for drinking water applications and critical RO pre-treatment stages.

Technical Note:

Our tanks undergo rigorous burst pressure and fatigue testing. For detailed structural stress analysis, raw material composition, or specific manufacturing protocols, please reference the official technical data at our specialized manufacturing division:

Stark Tank Manufacturing – 2.5″ NPSM Series Specs

Parámetros del producto

Use the chart below to select the correct vessel size based on your required resin volume or flow rate.

| Modelo | Volumen Capacidad | Dimensions (Dia x H) | Flow Rate (m³/h) | B2B Quote | ||

|---|---|---|---|---|---|---|

| Tipo | US Gal | Liters | Inch | mm | Reference | Action |

| STK-713 | 1.6 | 6 | 7″ x 13″ | Ø180 x 335 | 0.3-0.7 | Inquiry |

| STK-717 | 2.4 | 9 | 7″ x 17″ | Ø180 x 430 | 0.3-0.7 | Inquiry |

| STK-735 | 5.3 | 20 | 7″ x 35″ | Ø180 x 905 | 0.3-0.7 | Inquiry |

| STK-817 | 2.9 | 11 | 8″ x 17″ | Ø205 x 445 | 0.3-0.7 | Inquiry |

| STK-835 | 6.3 | 24 | 8″ x 35″ | Ø205 x 905 | 0.3-0.7 | Inquiry |

| STK-844 | 8.7 | 33 | 8″ x 44″ | Ø205 x 1130 | 0.3-0.7 | Inquiry |

| STK-935 | 8.7 | 33 | 9″ x 35″ | Ø230 x 905 | 0.5-1.2 | Inquiry |

| STK-942 | 10.3 | 39 | 9″ x 42″ | Ø230 x 1085 | 0.5-1.2 | Inquiry |

| STK-948 | 11.9 | 45 | 9″ x 48″ | Ø230 x 1230 | 0.5-1.2 | Inquiry |

| STK-1017 | 4.8 | 18 | 10″ x 17″ | Ø255 x 445 | 0.8-1.4 | Inquiry |

| STK-1035 | 10.3 | 39 | 10″ x 35″ | Ø255 x 905 | 0.8-1.4 | Inquiry |

| STK-1044 | 12.9 | 49 | 10″ x 44″ | Ø255 x 1130 | 0.8-1.4 | Inquiry |

| STK-1054 | 16.4 | 62 | 10″ x 54″ | Ø255 x 1390 | 0.8-1.4 | Inquiry |

| STK-1252 | 22.5 | 85 | 12″ x 52″ | Ø300 x 1340 | 0.8-1.5 | Inquiry |

| STK-1265 | 28.0 | 106 | 12″ x 65″ | Ø300 x 1650 | 0.8-1.5 | Inquiry |

| STK-1354 | 27.5 | 104 | 13″ x 54″ | Ø330 x 1400 | 1.2-2.3 | Inquiry |

| STK-1665 | 49.7 | 188 | 16″ x 65″ | Ø400 x 1670 | 1.2-2.3 | Inquiry |

*Flow rates are for reference only. Please consult our engineers for specific system design parameters.

Industria aplicable

- Water Softening Systems:

Ideal housing for cation exchange resin to remove calcium and magnesium hardness in residential and industrial boiler feed water. - Activated Carbon Filtration:

Used for de-chlorination, organics removal, and taste/odor improvement in municipal water supply lines. - RO Pre-Treatment:

Acts as the primary sand/multimedia filter to protect sensitive Reverse Osmosis membranes from sediment and particulate fouling.

Ventaja Uno

Corrosion-Resistant Composite Construction

Stark FRP vessels are engineered to outlast traditional steel tanks in aggressive water environments. The inner shell is molded from seamless, food-grade High-Density Polyethylene (HDPE), ensuring that water never touches metal. This guarantees zero rust and no heavy metal leaching.The outer shell is reinforced with continuous strands of fiberglass embedded in high-performance epoxy resin, providing a pressure rating of 150 PSI (10.5 Bar) while being 60% lighter than steel equivalents.Ventaja DOS

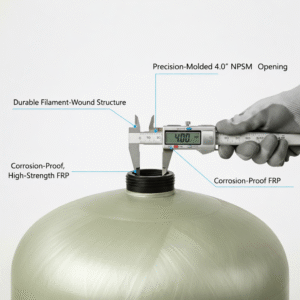

Universal Compatibility & Easy Maintenance

Designed with the system integrator in mind, the 2.5″ NPSM threaded top opening is manufactured with precision tolerances to ensure a leak-free seal with all major control valve brands, including Runxin, Fleck, Clack, and Autotrol.The lightweight composite structure simplifies transport and installation, allowing a single technician to position the tank and load media (Resin, Carbon, or Sand) without the need for heavy lifting equipment.Productos relacionados

Productos relacionados

PREGUNTAS FRECUENTES

P1: ¿Cuánto dura el sistema de ósmosis inversa?

La vida útil de un sistema de ósmosis inversa depende de la calidad del agua y del mantenimiento. Normalmente, la membrana dura entre 2 y 3 años, mientras que el sistema en sí puede durar más de 10 años con los cuidados adecuados.

P2: ¿Se puede personalizar el sistema en función de las diferentes condiciones del agua?

Sí, todos nuestros sistemas son totalmente personalizables. Analizamos su informe de aguas y sus necesidades de aplicación antes de ofrecerle soluciones a medida.

P3: ¿Qué normas cumplen los equipos STARK?

Nuestros productos cumplen las normas CE e ISO 9001, y pueden diseñarse para cumplir normativas regionales o estándares industriales específicos si así se solicita.

P4: ¿Cuál es el plazo de entrega de los sistemas de ósmosis inversa STARK?

Los sistemas estándar se envían en un plazo de 7-15 días. Para los pedidos personalizados, el plazo de entrega puede prolongarse hasta 20-25 días en función de la complejidad.

P5: ¿Ofrecen asistencia técnica u orientación para la instalación?

Sí. Proporcionamos documentación técnica completa, asistencia remota por vídeo y podemos enviar ingenieros al extranjero si así se solicita.

P6: ¿Qué incluye su presupuesto?

Nuestro presupuesto incluye el sistema de ósmosis inversa completo, el panel de control, las bombas, las unidades de pretratamiento y todos los accesorios necesarios. Si lo desea, podemos incluir herramientas de instalación y piezas de repuesto.