Stark Commercial High-Flow 4 NPSM Pressure Vessel Series

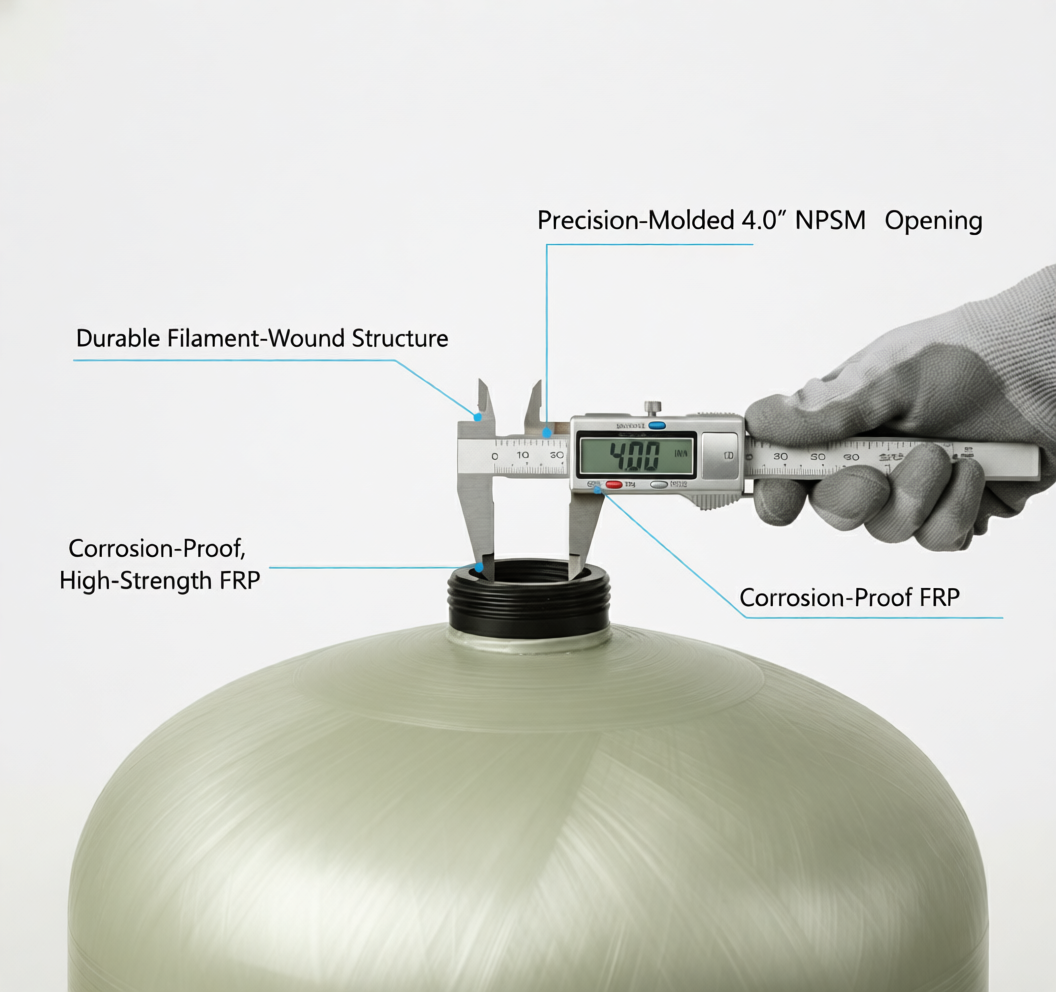

The Stark commercial **4 NPSM pressure vessel** features a wide threaded top opening engineered for high-flow industrial water treatment. This heavy-duty tank eliminates pressure drop bottlenecks and is fully compatible with 1.5″ to 2″ control valves, making it ideal for large-scale boiler feed and hotel water systems.

Descripción del producto

The Industrial Workhorse: High-Flow 4 NPSM Pressure Vessel.

The Stark **4 NPSM pressure vessel** series is designed to meet the rigorous demands of high-volume commercial and industrial applications. As vessel diameter increases (14″ to 36″), standard openings create a “choke point” that restricts flow. Our 4″ NPSM design solves this by providing a significantly larger cross-sectional area, allowing for higher service flow rates and vigorous backwashing of heavy media.

Constructed with a thickened fiberglass winding layer over a seamless PE liner, these tanks offer superior structural integrity to handle the immense weight of large media beds while maintaining a 150 PSI pressure rating.

Engineering Data:

Large-diameter vessels require strict fatigue analysis to ensure safety under load. For cycle pressure test reports, resin loading calculations, and dimensional drawings, please reference the official technical data at our specialized manufacturing division:

Stark Tank Manufacturing – 4″ NPSM Industrial Series Specs

.

Parámetros del producto

Below are the verified specifications for our 4″ NPSM top-mount series. These high-flow tanks are designed for commercial and industrial applications.

| Modelo | Volumen Capacidad | Dimensions (Dia x H) | Flow Rate (m³/h) | B2B Quote | ||

|---|---|---|---|---|---|---|

| Tipo | US Gal | Liters | Nominal | mm | Range | Action |

| STK-1465 | 38.6 | 146 | 14″ x 65″ | Ø355 x 1670 | 1.2-2.3 | Inquiry |

| STK-1665 | 49.7 | 188 | 16″ x 65″ | Ø400 x 1670 | 1.5-3.8 | Inquiry |

| STK-1865 | 62.9 | 238 | 18″ x 65″ | Ø450 x 1670 | 2.5-4.7 | Inquiry |

| STK-2162 | 83.5 | 316 | 21″ x 62″ | Ø530 x 1780 | 3.0-6.0 | Inquiry |

| STK-2472 | 109.6 | 415 | 24″ x 72″ | Ø600 x 1920 | 4.2-8.4 | Inquiry |

| STK-3072 | 169.1 | 640 | 30″ x 72″ | Ø750 x 1920 | 6.6-13.0 | Inquiry |

| STK-3672 | 264.2 | 1000 | 36″ x 72″ | Ø900 x 2150 | 9.5-19.0 | Inquiry |

*Note: US dimensions are nominal. Flow rates are for reference. Please consult our engineers for precise system design.

Industria aplicable

- Commercial Building Supply:

Centralized water softening for hotels, resorts, and hospitals, supporting high peak-flow demands. - Industrial Boiler Feed:

High-capacity removal of hardness minerals to prevent scaling in industrial boilers and cooling towers. - Large Scale RO Pre-Treatment:

Robust multimedia filtration for commercial Reverse Osmosis systems (1000+ LPH capacity).

Ventaja Uno

Maximized Flow & Low Pressure Drop

The 4″ NPSM top opening is a critical upgrade for commercial systems. By pairing with 1.5″ or 2″ control valves, this series minimizes pressure drop during service flow and ensures sufficient water velocity for backwashing.This is essential for heavy media beds (like Pyrolox or Greensand) that require vigorous expansion to prevent fouling, ensuring your system operates efficiently for years.Ventaja DOS

Heavy-Duty Structural Integrity

Larger tank diameters require superior structural reinforcement. Stark 4″ NPSM vessels feature a thickened fiberglass winding layer and a reinforced base design to withstand the static load of tons of filter media.Rated for 150 PSI (10.5 Bar) and cycle-tested for fatigue resistance, these tanks are built to perform reliably in harsh industrial plant environments.Productos relacionados

Productos relacionados

- Accesorios para el tratamiento del agua

Stark LP-4040 Industrial RO Membrane Element (High Flux 5L/min, 99.2% Rejection)

Leer más

PREGUNTAS FRECUENTES

P1: ¿Cuánto dura el sistema de ósmosis inversa?

La vida útil de un sistema de ósmosis inversa depende de la calidad del agua y del mantenimiento. Normalmente, la membrana dura entre 2 y 3 años, mientras que el sistema en sí puede durar más de 10 años con los cuidados adecuados.

P2: ¿Se puede personalizar el sistema en función de las diferentes condiciones del agua?

Sí, todos nuestros sistemas son totalmente personalizables. Analizamos su informe de aguas y sus necesidades de aplicación antes de ofrecerle soluciones a medida.

P3: ¿Qué normas cumplen los equipos STARK?

Nuestros productos cumplen las normas CE e ISO 9001, y pueden diseñarse para cumplir normativas regionales o estándares industriales específicos si así se solicita.

P4: ¿Cuál es el plazo de entrega de los sistemas de ósmosis inversa STARK?

Los sistemas estándar se envían en un plazo de 7-15 días. Para los pedidos personalizados, el plazo de entrega puede prolongarse hasta 20-25 días en función de la complejidad.

P5: ¿Ofrecen asistencia técnica u orientación para la instalación?

Sí. Proporcionamos documentación técnica completa, asistencia remota por vídeo y podemos enviar ingenieros al extranjero si así se solicita.

P6: ¿Qué incluye su presupuesto?

Nuestro presupuesto incluye el sistema de ósmosis inversa completo, el panel de control, las bombas, las unidades de pretratamiento y todos los accesorios necesarios. Si lo desea, podemos incluir herramientas de instalación y piezas de repuesto.