Bomba centrífuga multietapas horizontal Cnp de alta presión bomba de agua residual de acero inoxidable con depósito de presión

Power your water transfer needs with Stark Water’s High Pressure Cnp Horizontal Multistage Centrifugal Pump. This robust horizontal multistage centrifugal pump, crafted from stainless steel, is ideal for high-pressure applications including clean water supply and even sewage transfer with an integrated pressure tank, ensuring reliable and efficient fluid management.

Descripción del producto

Efficient and reliable fluid transfer under high pressure is a cornerstone of many industrial, commercial, and even domestic water systems. The Stark Water High Pressure Cnp Horizontal Multistage Centrifugal Pump is meticulously engineered to deliver exceptional performance in these demanding applications. This versatile pump combines powerful hydraulics with durable construction, making it an ideal choice for a wide array of high-head, high-pressure liquid transfer tasks, from clean water boosting to specific sewage handling.

Superior Performance with Horizontal Multistage Centrifugal Design

At the heart of this system is its horizontal multistage centrifugal pump design. Unlike single-stage pumps, a multistage design incorporates multiple impellers in series. Each impeller progressively increases the pressure, allowing the pump to achieve significantly higher discharge pressures and greater head capabilities. This makes it exceptionally efficient for applications requiring water to be lifted to considerable heights, transported over long distances, or delivered at high pressure for various processes. The horizontal configuration allows for easier installation, inspection, and maintenance compared to vertical counterparts, making it a practical choice for many setups.

Robust Stainless Steel Construction for Durability and Versatility

Constructed from high-grade acero inoxidable, this pump offers outstanding corrosion resistance. This is crucial for ensuring the longevity and reliability of the pump, especially when handling various water types. While explicitly highlighted as a “sewage water pump” in its broader application scope, the stainless steel construction also makes it highly suitable for clean water boosting, industrial process water transfer, and general utility applications where clean, non-abrasive liquids are involved. Its durability ensures consistent performance even under continuous, demanding operating conditions.

Integrated Pressure Tank for Consistent Supply

A significant advantage of this pump system is the inclusion of an **integrated pressure tank**. This tank works in conjunction with the pump to maintain system pressure and reduce pump cycling. When water is consumed, the pressure in the tank drops, triggering the pump to turn on and replenish the supply. Once the desired pressure is reached, the pump turns off. This not only provides a consistent and smooth water supply without fluctuations but also reduces wear and tear on the pump, extending its operational lifespan and minimizing energy consumption associated with frequent start/stop cycles. This makes it particularly effective for automatic water supply systems.

High Pressure Power for Diverse Applications

Designed for **high pressure power**, this pump excels in scenarios where significant force is required to move liquids. This capability makes it invaluable for:

- Boosting water pressure in residential, commercial, and industrial buildings.

- Water supply to high-rise buildings and remote locations.

- Boiler feed applications.

- Reverse Osmosis (RO) system feed pumps (for specific pressure ranges).

- General industrial process water transfer.

- Efficient transfer of filtered sewage or greywater (where stainless steel is suitable for corrosion and abrasion, typically post-screening/treatment).

The Stark Water Cnp Horizontal Multistage Centrifugal Pump delivers a reliable, efficient, and robust solution for your most challenging fluid transfer needs.

Parámetros del producto

| Parámetro | Especificaciones / Opciones de personalización |

|---|---|

| Palabras clave principales | Horizontal multistage centrifugal pump diseño y rendimiento. |

| Tipo de bomba | Horizontal Multistage Centrifugal Pump |

| Brand | CNP (or equivalent high-quality manufacturer) |

| Material de construcción | Stainless Steel (SUS304 or SUS316, for pump casing, impeller, shaft) |

| Potencia del motor | Varies by model and head/flow requirements (e.g., 0.75 kW to 7.5 kW or higher) |

| Tensión y frecuencia | Single Phase 220V/50Hz or Three Phase 380V/50Hz (customizable for 60Hz/other voltages) |

| Caudal | Varies by model (e.g., 2 m³/hr to 25 m³/hr, up to 100+ m³/hr for larger models) |

| Max. Head | Varies significantly by model (e.g., 20m to 150m or more) |

| Máx. Presión de funcionamiento | Typically 1.0 MPa (10 Bar) to 2.5 MPa (25 Bar), depends on model. |

| Tamaño de entrada/salida | Standard threaded (NPT/BSP) or flanged connections, sizes from 1″ to 3″ (or larger). |

| Integrated Component | Pressure Tank (sized appropriately for pump capacity and application) |

| Temperatura del líquido | Typically -15°C to 100°C (depending on seal materials). |

| Application Suitability | Clean Water, Industrial Process Water, High Pressure Boosting, Water Supply, Mild Sewage/Greywater (if pre-filtered/non-abrasive). |

| Tipo de junta | Mechanical Seal (e.g., Ceramic/Graphite/SiC) |

| Clase de protección | IP55 (Motor) |

| Clase de aislamiento | F |

Industria aplicable

- High-Rise Building Water Supply: Provides reliable and consistent water pressure for multi-story residential, commercial, and office buildings.

- Industrial Water Boosting: Boosts pressure for process water, cooling water, and general utility water in factories, manufacturing plants, and industrial complexes.

- Agricultural Irrigation: Efficiently transfers water over long distances or to higher elevations for large-scale agricultural irrigation systems.

- Fire Fighting Systems: Can serve as a booster pump in fire suppression systems, ensuring adequate pressure for fire hoses.

- Agua de alimentación de la caldera: Supplies high-pressure water to boilers for steam generation in power plants and industrial facilities.

- Reverse Osmosis (RO) Systems: Acts as a reliable booster or feed pump for various RO water treatment plants, providing the necessary high pressure for membrane operation.

- Water Treatment & Filtration: Used in various stages of water treatment processes requiring high pressure for filtration, backwash, or transfer.

- HVAC & Cooling Towers: Circulates water in heating, ventilation, and air conditioning systems, and provides make-up water for cooling towers.

- Mining & Construction: Used for dewatering, transfer of non-abrasive fluids, and other high-pressure water handling tasks on site.

- Light Industrial Sewage/Greywater Transfer: With its stainless steel construction, it’s suitable for transferring pre-filtered or non-abrasive sewage/greywater in specific industrial or commercial settings where hygienic and corrosion-resistant pumping is required.

Ventaja Uno

Ventaja DOS

Productos relacionados

Productos relacionados

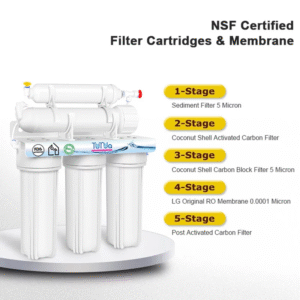

- Sistema de ósmosis inversa

Sistema de tratamiento de agua por ósmosis inversa 500L/H | STARK Water

Leer más - Purificador de agua doméstico

Purificador de agua doméstico de ósmosis inversa 75GPD | Filtro purificador de agua de 5 etapas

Leer más

PREGUNTAS FRECUENTES

P1: ¿Cuánto dura el sistema de ósmosis inversa?

La vida útil de un sistema de ósmosis inversa depende de la calidad del agua y del mantenimiento. Normalmente, la membrana dura entre 2 y 3 años, mientras que el sistema en sí puede durar más de 10 años con los cuidados adecuados.

P2: ¿Se puede personalizar el sistema en función de las diferentes condiciones del agua?

Sí, todos nuestros sistemas son totalmente personalizables. Analizamos su informe de aguas y sus necesidades de aplicación antes de ofrecerle soluciones a medida.

P3: ¿Qué normas cumplen los equipos STARK?

Nuestros productos cumplen las normas CE e ISO 9001, y pueden diseñarse para cumplir normativas regionales o estándares industriales específicos si así se solicita.

P4: ¿Cuál es el plazo de entrega de los sistemas de ósmosis inversa STARK?

Los sistemas estándar se envían en un plazo de 7-15 días. Para los pedidos personalizados, el plazo de entrega puede prolongarse hasta 20-25 días en función de la complejidad.

P5: ¿Ofrecen asistencia técnica u orientación para la instalación?

Sí. Proporcionamos documentación técnica completa, asistencia remota por vídeo y podemos enviar ingenieros al extranjero si así se solicita.

P6: ¿Qué incluye su presupuesto?

Nuestro presupuesto incluye el sistema de ósmosis inversa completo, el panel de control, las bombas, las unidades de pretratamiento y todos los accesorios necesarios. Si lo desea, podemos incluir herramientas de instalación y piezas de repuesto.