Planta de tratamiento de agua Elementos de cartucho de filtro de membrana de ósmosis inversa Sustitución de la membrana de ósmosis inversa

Descripción del producto

Each membrane element is housed in a durable, chemical-resistant wrap that ensures stability under varying pressures and temperatures. With consistent salt rejection rates (up to 98.5%) and a high permeate flow rate, our RO membrane cartridges are ideal for applications that demand purity, efficiency, and reliability.

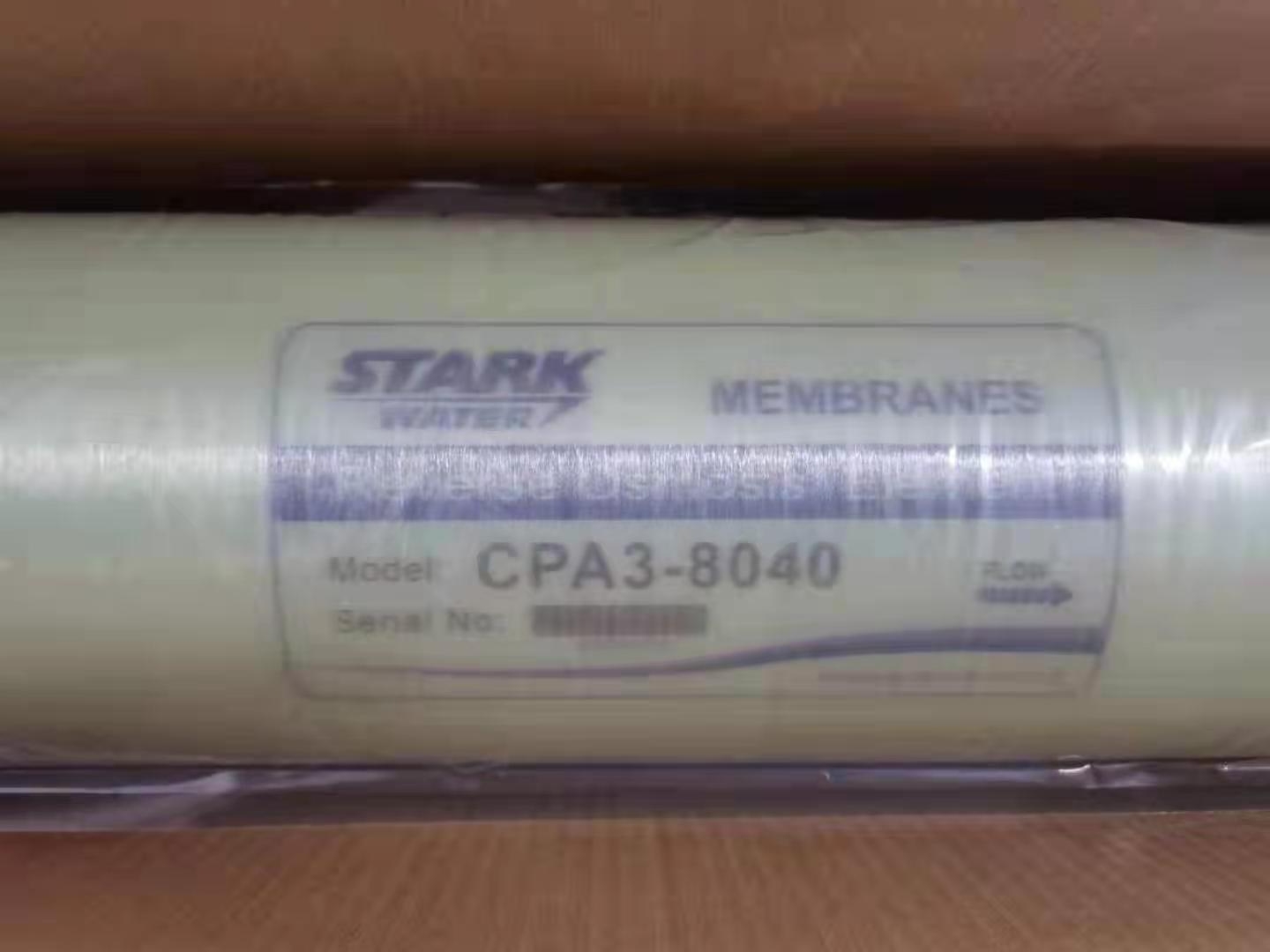

STARK provides a wide range of configurations—including 4040 and 8040 sizes—suitable for small commercial RO systems to large-scale municipal water plants. Each membrane undergoes quality control testing to ensure performance consistency before shipping.

Whether used as a replacement cartridge or as part of a new installation, STARK’s membrane elements are designed to integrate smoothly with standard reverse osmosis systems, offering minimized downtime and easy replacement procedures. The membranes are suitable for brackish water, tap water, and pre-treated seawater systems.

Industries we serve include pharmaceutical manufacturing, food & beverage processing, electronics production, and municipal drinking water treatment. The cartridges also support custom OEM/ODM requirements to match specialized RO system designs.

Parámetros del producto

- Product Type: Reverse Osmosis Membrane Cartridge

- Membrane Material: Thin-Film Composite (TFC)

- Available Sizes: 4040 / 8040 (Custom sizes available upon request)

- Presión de funcionamiento: 150 – 300 psi (10 – 20 bar)

- Max Operating Temperature: 45°C (113°F)

- Tasa de rechazo de sal: ≥98.5%

- Permeate Flow Rate: 2400 – 11000 GPD (depending on size)

- pH Range (Continuous Operation): 3 – 10

- Chlorine Tolerance: <0.1 ppm (pre-treatment required)

- Connector Type: Standard male/female end caps or customized fittings

- Certifications: ISO 9001, CE (optional NSF on request)

Industria aplicable

- Farmacéutica y biotecnología: Used in ultra-pure water systems for drug formulation, rinsing, and lab-grade applications.

- Food & Beverage: Applied in bottled water production, ingredient blending, and CIP rinse cycles to meet hygiene standards.

- Electronics & Semiconductors: Ensures ultrapure water quality for chip cleaning, circuit board manufacturing, and precision rinsing processes.

- Municipal Water Supply: Integrated into public water treatment plants for removing hardness, heavy metals, and pathogens.

- Seawater Desalination: Used in brackish and seawater RO systems for producing potable or industrial-grade water.

- Chemical & Textile Industries: Facilitates demineralized water generation for chemical blending, dyeing, and rinsing operations.

- Commercial Buildings & Institutions: Installed in schools, hospitals, and hotels to ensure safe and reliable water delivery.

Ventaja Uno

Advantage 1: Superior Filtration Efficiency

The STARK reverse osmosis membrane cartridge delivers exceptional salt rejection performance, achieving up to 98.5% removal of dissolved solids, organics, and heavy metals. Its advanced thin-film composite structure ensures optimal filtration precision while maintaining high flow rates. This results in reduced energy consumption and enhanced operational efficiency, especially in large-scale water treatment applications. Whether you’re operating in a pharmaceutical-grade clean environment or a high-demand industrial process, the membrane maintains consistent water quality over extended operation periods.Ventaja DOS

Advantage 2: Durability and Easy Maintenance

Constructed with robust, high-performance materials, the STARK reverse osmosis membrane cartridge is engineered to withstand harsh water conditions and long operational hours. Its chlorine-tolerant design (≤0.1 ppm) and broad pH compatibility (3–10) help reduce fouling and membrane degradation, ensuring extended service life. The standardized 4040 and 8040 configurations allow for easy installation and replacement, minimizing system downtime. With minimal cleaning cycles required and lower frequency of replacements, users benefit from reduced maintenance costs and higher system uptime—making it a cost-effective long-term solution for continuous water purification needs.Productos relacionados

Productos relacionados

- Accesorios para el tratamiento del agua

Stark LP-4040 Industrial RO Membrane Element (High Flux 5L/min, 99.2% Rejection)

Leer más

PREGUNTAS FRECUENTES

P1: ¿Cuánto dura el sistema de ósmosis inversa?

La vida útil de un sistema de ósmosis inversa depende de la calidad del agua y del mantenimiento. Normalmente, la membrana dura entre 2 y 3 años, mientras que el sistema en sí puede durar más de 10 años con los cuidados adecuados.

P2: ¿Se puede personalizar el sistema en función de las diferentes condiciones del agua?

Sí, todos nuestros sistemas son totalmente personalizables. Analizamos su informe de aguas y sus necesidades de aplicación antes de ofrecerle soluciones a medida.

P3: ¿Qué normas cumplen los equipos STARK?

Nuestros productos cumplen las normas CE e ISO 9001, y pueden diseñarse para cumplir normativas regionales o estándares industriales específicos si así se solicita.

P4: ¿Cuál es el plazo de entrega de los sistemas de ósmosis inversa STARK?

Los sistemas estándar se envían en un plazo de 7-15 días. Para los pedidos personalizados, el plazo de entrega puede prolongarse hasta 20-25 días en función de la complejidad.

P5: ¿Ofrecen asistencia técnica u orientación para la instalación?

Sí. Proporcionamos documentación técnica completa, asistencia remota por vídeo y podemos enviar ingenieros al extranjero si así se solicita.

P6: ¿Qué incluye su presupuesto?

Nuestro presupuesto incluye el sistema de ósmosis inversa completo, el panel de control, las bombas, las unidades de pretratamiento y todos los accesorios necesarios. Si lo desea, podemos incluir herramientas de instalación y piezas de repuesto.