Carcasa de membrana de acero inoxidable STARK 4040

Carcasa de membrana de acero inoxidable STARK 4040Carcasa de membrana de acero inoxidable STARK 4040

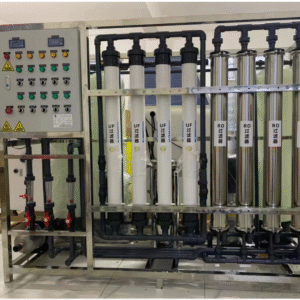

Ensure reliable performance and robust protection for your RO membranes with Stark Water’s 4040 Stainless Steel Membrane Housing. Este resistente stainless steel membrane housing is designed for 4040 RO elements, providing secure, leak-proof containment crucial for various industrial and commercial reverse osmosis systems.

Descripción del producto

In any efficient Reverse Osmosis (RO) system, the membrane housing serves as a critical component, providing the robust and secure environment necessary for RO membranes to function under high pressure. The STARK 4040 Stainless Steel Membrane Housing is meticulously engineered to deliver exceptional durability, reliability, and protection for your RO elements in demanding industrial and commercial applications. This housing stands as a testament to superior engineering, ensuring the longevity and optimal performance of your water purification infrastructure.

Built for 4040 RO Membranes

This **stainless steel membrane housing** is precisely designed to accommodate standard **4040 RO membrane** elements (4-inch diameter, 40-inch length). This common size makes our housing highly compatible with a wide range of industrial and commercial RO systems, offering versatile integration options. The internal dimensions are optimized to ensure a perfect fit for the membrane, preventing bypass of untreated water and maximizing the efficiency of the reverse osmosis process, thus ensuring consistently high-quality permeate production.

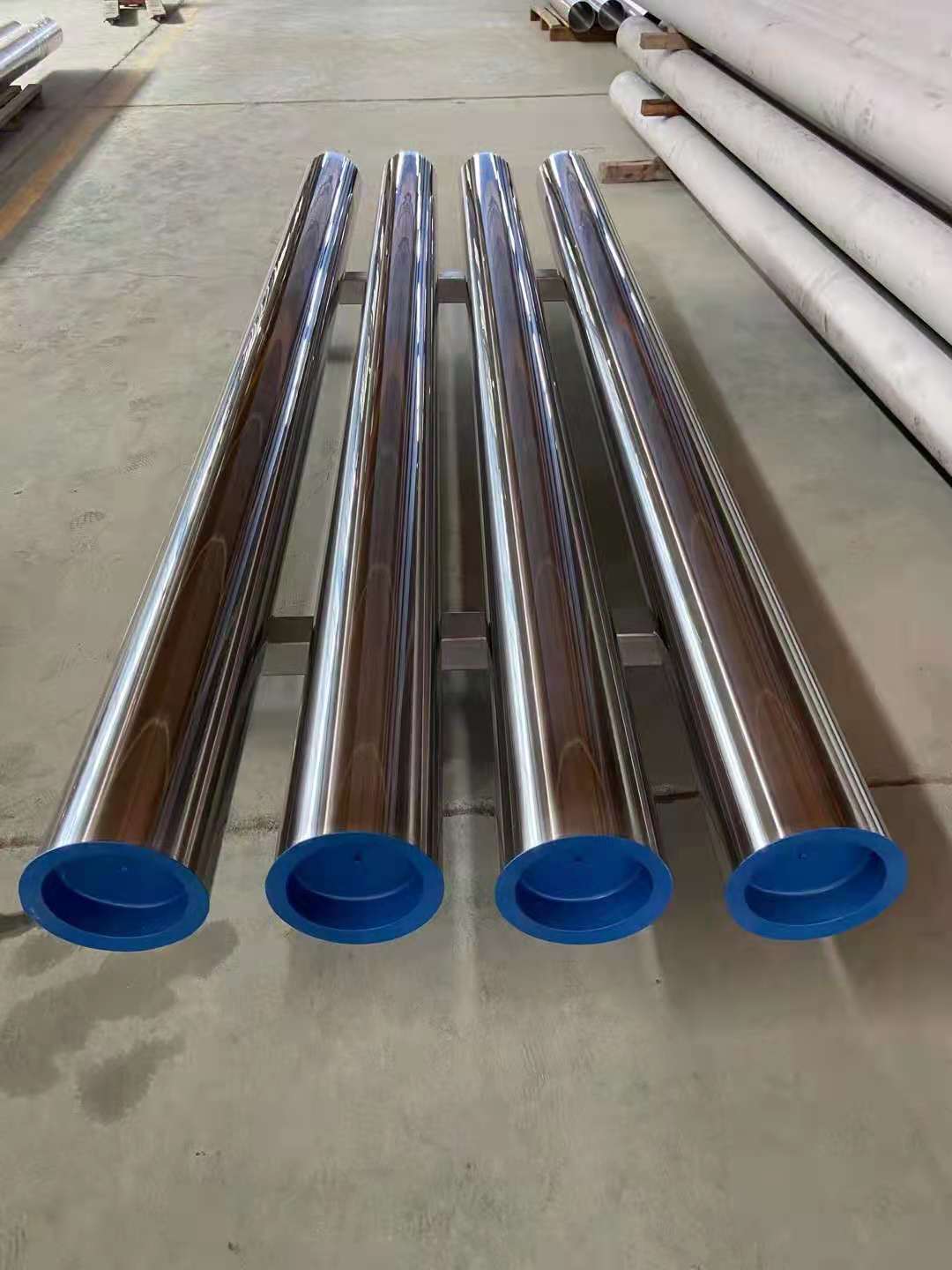

Premium Stainless Steel Construction & High-Pressure Resilience

Durability, corrosion resistance, and safety are paramount for any pressure-bearing component in water treatment. Our 4040 membrane housing is constructed exclusively from high-grade **stainless steel** (typically SUS304 or SUS316L, depending on the application’s specific requirements for corrosion resistance). This material choice provides exceptional resilience against aggressive water chemistries, corrosive environments, and high operating pressures common in RO systems. The robust construction allows the housing to safely contain the significant internal pressures (often ranging from 200-600 PSI or more for brackish and seawater applications) required for efficient RO operation, ensuring a secure and reliable containment vessel for your valuable membranes.

Absolutely Sealed Design for Uncompromised Purity

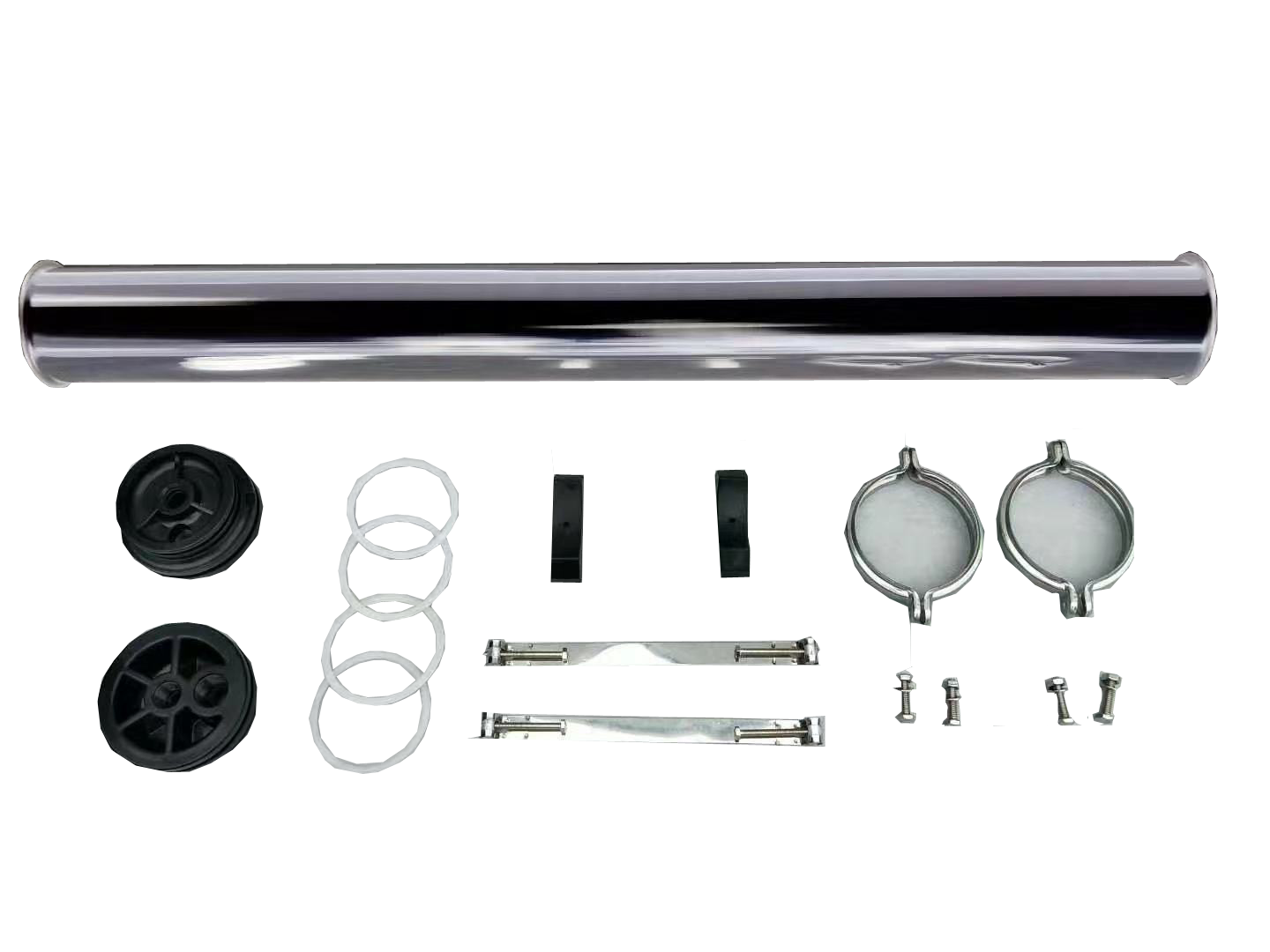

A hallmark of the STARK 4040 membrane housing is its **absolutely sealed design**. Precision machining and the use of high-quality, long-lasting O-rings ensure a leak-proof seal under all operating conditions. This critical design feature prevents any untreated feedwater from bypassing the RO membranes and contaminating the purified water stream. By guaranteeing that all liquid passes through the filtration process, our membrane housing contributes directly to consistently high-quality permeate, safeguarding your final product and the integrity of your downstream processes.

Ease of Installation, Maintenance, and Long-Term Value

Designed with practicality in mind, our stainless steel membrane housing facilitates straightforward installation and relatively easy maintenance. Its robust build and high-quality materials significantly reduce the need for frequent replacements or repairs, contributing to lower long-term operational costs. By providing superior protection for your sensitive RO membranes from external damage and ensuring efficient flow dynamics, our **stainless steel membrane housing** effectively extends the lifespan of your entire RO system. This translates into reliable, uninterrupted water purification and excellent value over the system’s operational life.

Parámetros del producto

| Parámetro | Especificaciones / Opciones de personalización |

|---|---|

| Palabras clave principales | Stainless Steel Membrane Housing diseño y capacidades. |

| Tamaño de membrana compatible | 4040 (4-inch diameter, 40-inch length) RO Membrane Elements. Can accommodate 1 to 3+ elements per vessel (depending on model). |

| Construcción material | Stainless Steel (SUS304 or SUS316L, specific grade can be chosen based on application and water chemistry). |

| Tipo de diseño | End-entry or Side-entry ports. Individual or multi-element configurations. |

| Máx. Presión de funcionamiento | Typically 300 PSI, 450 PSI, 600 PSI (designed to specific pressure requirements for brackish or clean water RO). |

| Máx. Temperatura de funcionamiento | Up to 49°C (120°F) – depending on sealing materials. |

| Permeate Port Size | Standard ¾” or 1″ NPT/BSP. |

| Concentrate/Inlet Port Size | Standard 1″ or 1.5″ NPT/BSP. |

| Material de la tapa | Stainless Steel (compatible with housing material) or durable ABS/PVC. |

| Material de sellado | EPDM, Viton (FKM), Buna-N (NBR) O-rings (selected based on chemical compatibility and temperature). |

| Acabado superficial | Polished or Pickled/Passivated (internal and external) for enhanced corrosion resistance. |

| Mounting Saddles | Included stainless steel saddles for secure mounting. |

| Pruebas y certificación | Pressure tested; ASME code stamp available upon request for specific pressure vessel requirements. |

Industria aplicable

- Plantas de tratamiento de aguas industriales: Serving as the core containment for 4040 RO membranes in various systems providing purified water for manufacturing processes, utility, and general industrial use.

- Industria de alimentación y bebidas: Used in RO systems that produce high-purity process water for bottled water production, beverage formulation, dairy processing, and food ingredient preparation, ensuring product consistency and safety.

- Industria farmacéutica y médica: Critical for RO systems generating Purified Water (PW), pre-treatment for Water for Injection (WFI), and other high-purity water requirements for drug manufacturing and medical device reprocessing, adhering to strict GMP standards.

- Laboratorios e instalaciones de investigación: Essential for housing RO membranes that supply high-purity water for analytical testing, reagent preparation, and sensitive experimental procedures.

- Commercial & Institutional Water Supply: For RO systems providing purified drinking water for hotels, resorts, schools, hospitals (non-critical areas), and large commercial buildings.

- Generación de energía: Utilized in RO systems for boiler feed water pre-treatment and cooling tower make-up water, preventing scaling and corrosion in expensive equipment and improving energy efficiency.

- Brackish Water Treatment: For purifying groundwater with high mineral content for various commercial, agricultural, and municipal applications.

- Tratamiento y reutilización de aguas residuales: Employed in RO stages of advanced wastewater treatment facilities to produce high-quality effluent for discharge or reuse, especially in smaller scale industrial processes.

- Automotive & Metal Finishing: Used in RO systems to provide high-purity rinse water for electroplating, painting, and metal treatment processes, improving finish quality and reducing defects.

Ventaja Uno

Ventaja DOS

Productos relacionados

Productos relacionados

PREGUNTAS FRECUENTES

P1: ¿Cuánto dura el sistema de ósmosis inversa?

La vida útil de un sistema de ósmosis inversa depende de la calidad del agua y del mantenimiento. Normalmente, la membrana dura entre 2 y 3 años, mientras que el sistema en sí puede durar más de 10 años con los cuidados adecuados.

P2: ¿Se puede personalizar el sistema en función de las diferentes condiciones del agua?

Sí, todos nuestros sistemas son totalmente personalizables. Analizamos su informe de aguas y sus necesidades de aplicación antes de ofrecerle soluciones a medida.

P3: ¿Qué normas cumplen los equipos STARK?

Nuestros productos cumplen las normas CE e ISO 9001, y pueden diseñarse para cumplir normativas regionales o estándares industriales específicos si así se solicita.

P4: ¿Cuál es el plazo de entrega de los sistemas de ósmosis inversa STARK?

Los sistemas estándar se envían en un plazo de 7-15 días. Para los pedidos personalizados, el plazo de entrega puede prolongarse hasta 20-25 días en función de la complejidad.

P5: ¿Ofrecen asistencia técnica u orientación para la instalación?

Sí. Proporcionamos documentación técnica completa, asistencia remota por vídeo y podemos enviar ingenieros al extranjero si así se solicita.

P6: ¿Qué incluye su presupuesto?

Nuestro presupuesto incluye el sistema de ósmosis inversa completo, el panel de control, las bombas, las unidades de pretratamiento y todos los accesorios necesarios. Si lo desea, podemos incluir herramientas de instalación y piezas de repuesto.