Summary: This practical guide explains Limpieza de la membrana de ósmosis inversa—what problems it solves, objective triggers to start a clean, how to choose the right chemistry, and a validated step-by-step SOP. You’ll also get acceptance criteria, troubleshooting, safety and a preventive program to extend membrane life.

Reviewed by Stark Water Process Engineering Team • Last updated: 2025-10-20

1) What RO membrane cleaning solves

Over time, reverse osmosis elements lose performance due to inorganic scale (e.g., CaCO3, CaSO4), organics/colloids, biofoulingy metal oxides. A well-executed cleaning restores normalized flux, lowers differential pressure (ΔP), improves salt rejection and postpones costly membrane replacement.

2) When to clean: objective triggers

| Trigger | Typical threshold | Notas |

|---|---|---|

| Normalized permeate flow drop | 10–15% below baseline | Use normalized data to remove temp/pressure effects. |

| Salt rejection decline | ≥5% worse than baseline | Monitor product conductivity or salt passage. |

| Feed pressure increase | 15–20% higher at same setpoint | Indicates fouling or scaling. |

| Stage / bank ΔP | > 0.15 MPa (≈ 1.5 bar) rise | Check interstage distribution and air entrapment. |

| Preventive cadence | Every 3-6 meses in continuous service | Shorten interval for high-foulant feed waters. |

3) Diagnose fouling & pick the chemistry

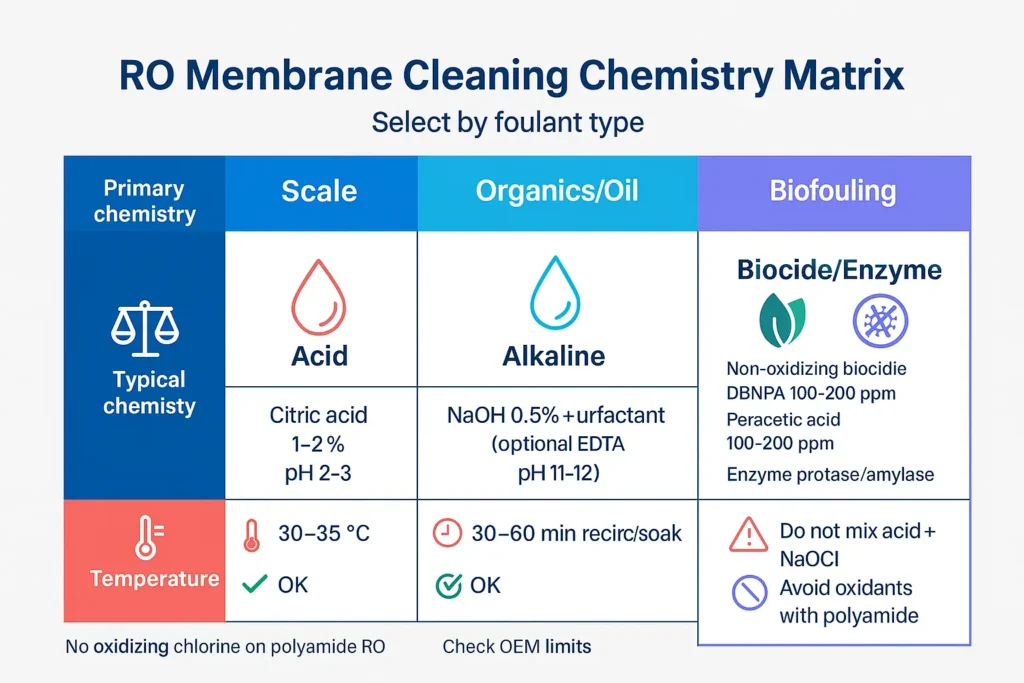

Match observed symptoms to chemistry. When in doubt, start with alkaline for organics, then acid for scale—rinsing thoroughly between passes.

| Fouling type | Field indicators | Primary chemistry | Setpoints | Compatibility & notes |

|---|---|---|---|---|

| Inorganic scale (CaCO3, CaSO4, Ba/Sr) | High ΔP; efficiency improves during acid recirc | Citrate / HCl (dilute) | pH 2–3, 25–35 °C | Do not exceed OEM temp/pressure; flush thoroughly. |

| Organics / colloids | Tea-colored rinse; SDI high; flux slow to recover | NaOH + surfactant (optionally EDTA) | pH 10–12, 25–35 °C | Rinse to neutral before any acid pass. |

| Biofouling | Slime, odor; rapid ΔP rebound post-start | Alkaline + compatible biocide or enzyme | pH 10–12, per supplier label | No free chlorine on polyamide; verify residual = 0. |

| Metal oxides (Fe/Mn/Al) | Rust-colored rinse; upstream metal carryover | Alkaline + chelant (EDTA) | pH 10–11, 25–35 °C | Improve pretreatment filtration/oxidation. |

| Silica trend | High permeate conductivity not improving with acid | Alkaline with dispersant; manage pH/temperature | Per supplier | Control silica in feed; consider anti-scalant and pH. |

4) RO membrane cleaning procedure (SOP)

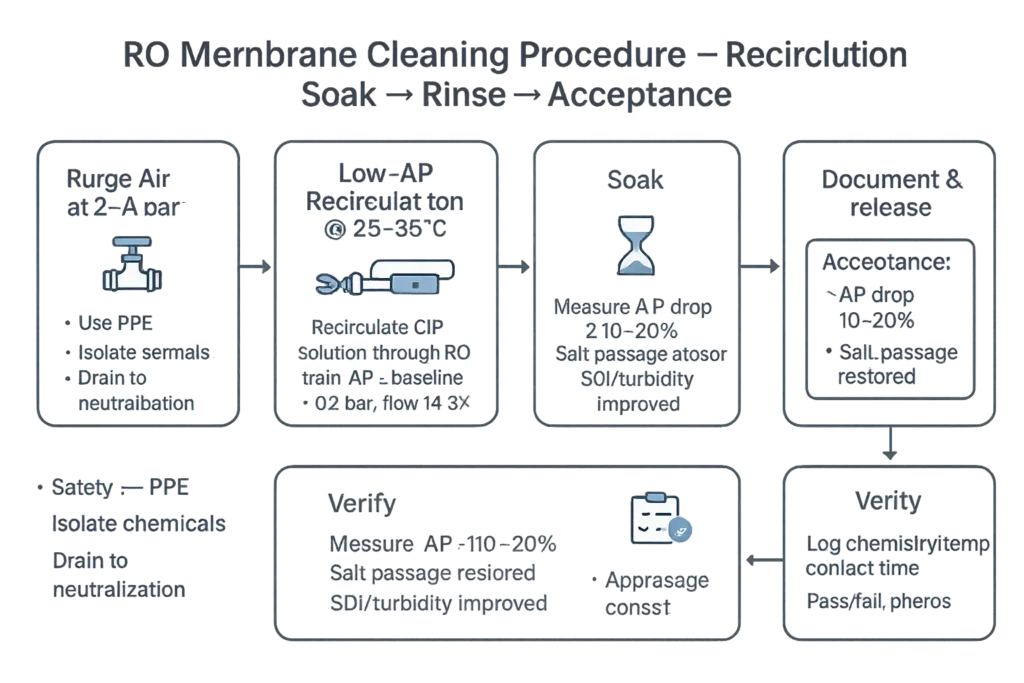

4.1 Preparation

- Isolate and lockout/tagout. Verify zero energy (electrical/pneumatic/hydraulic).

- Record baseline: normalized permeate flow, rejection, stage ΔP, temperatures.

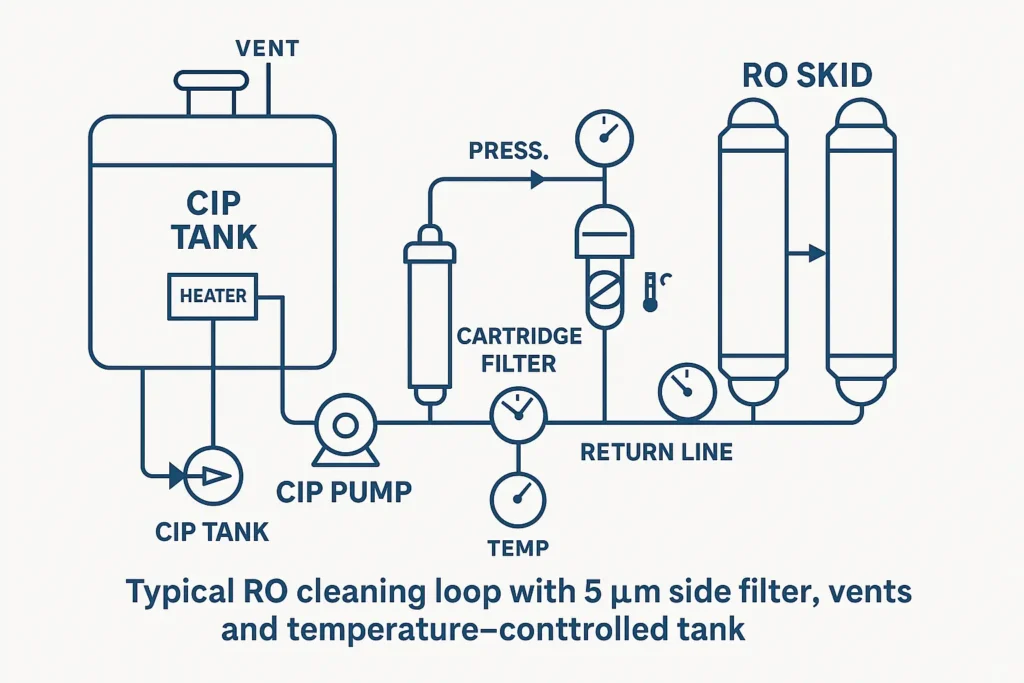

- Install a 5 µm side filter in the cleaning loop; confirm vent paths.

4.2 Mix cleaning solution

- Prepare chemical in the CIP tank using RO permeate or DI water.

- Adjust pH y temperatura to the targets above.

- Size volume to fully fill housings and recirculate with 1–2 tank volumes margin.

4.3 Recirculate at low pressure

- Open vents; purge entrapped air at 2–4 bar; then recirculate at ~1/3 normal ΔP.

- Maintain 30–60 min per stage, keeping crossflow high and permeate valve cracked open if OEM allows.

4.4 Soak

- Soak 1–2 h static. Keep temperature and pH within the window.

- Agitate briefly every 15–20 min to refresh boundary layers.

4.5 Rinse to neutral

- Flush with RO/DI water until discharge pH ≈ 7 and conductivity stabilizes.

- For mixed fouling: alkaline pass → rinse → acid pass → rinse.

4.6 Return to service

- Ramp up slowly while monitoring ΔP and product quality.

- Log post-clean normalized data and compare to acceptance criteria below.

5) Acceptance criteria & documentation

| Metric | Target (post-clean) | Notas |

|---|---|---|

| Normalized permeate flow | ≥ 90% of baseline | Site target may be 92–95% for critical service. |

| Rechazo de la sal | Near commissioning spec | Check both conductivity and salt passage. |

| Stage / element ΔP | Back within design window | Persistent high ΔP → inspect interconnectors, spacers, air. |

Recordkeeping: keep a signed log (chemicals, pH, temp, times), photos, tag IDs and instrument trends. Attach MSDS and rinse-neutralization records.

6) Troubleshooting if recovery is poor

- Wrong chemistry/sequence: run alkaline then acid; add chelant/surfactant per diagnosis.

- Low crossflow / trapped air: increase recirc, open vents, verify pumps/valves.

- Temperature or pH off-spec: re-heat or re-titrate solution.

- Irreversible fouling or damage: check for oxidation, compaction, or spacer blockage—consider element replacement.

- Rapid re-fouling: fix pretreatment (SDI/NTU), antiscalant dose and dechlorination control.

7) Safety & compliance

- Siga lockout/tagout, chemical PPE and eyewash/shower requirements.

- Respect polyamide limits: no free chlorine; follow OEM max temperature/pressure.

- Neutralize and dispose spent solutions per local regulations; document pH and volume.

8) Preventive program to extend membrane life

- Stabilize pretreatment: multimedia/UF as needed; maintain SDI < 3, NTU low.

- Optimize pH and antiincrustante; manage silica and LSI/CaSO4 indices.

- Control biogrowth: upstream chlorination → thorough dechlorination (SBS) just before RO.

- Set a cleaning cadence (e.g., quarterly) and trend normalized KPIs weekly.

9) Tools, references & internal links

- RO system commissioning checklist

- RO membrane installation diagram

- Calculators (LSI, OPEX, chlorine/SBS)

- Water Quality Association (WQA) guidance

- ISPE cleaning & sanitization resources

10) Request a quote / speak to an engineer

Share your normalized data and a recent water analysis—we’ll confirm the Limpieza de la membrana de ósmosis inversa recipe, size your CIP skid and propose improvements to pretreatment and controls.