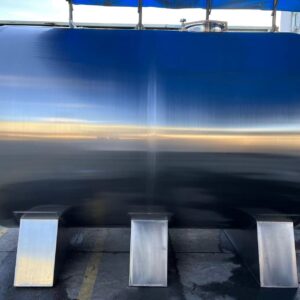

Réservoir de stockage d'eau en acier inoxydable 1000L, sur mesure pour l'industrie, réservoir sous pression

Get a robust 10000 gallon stainless steel water storage tank from Stark Water, custom-engineered for your industrial needs. This durable pressure vessel ensures safe and hygienic storage for large volumes of water, offering reliable performance and long-term value for diverse industrial applications.

Description du produit

For industrial operations that demand high-capacity, durable, and hygienic water storage, the Stark Water Industrial Customized 10000 Gallon Stainless Steel Water Storage Tank offers a premier solution. This isn’t a standard off-the-shelf product; it’s a meticulously engineered pressure vessel designed to meet the rigorous demands of large-scale industrial water management, ensuring safety, purity, and operational efficiency for your critical processes.

Massive Capacity, Custom-Engineered for Your Industry

With an impressive capacity of 10000 gallon stainless steel water storage tank, this stainless steel water storage tank** is built for substantial industrial requirements. Its truly customized nature sets it apart. We understand that large-scale industrial facilities have unique space constraints, flow dynamics, and specific operational requirements. Our engineering team works to tailor every aspect of the tank—from precise dimensions and connection types to specific pressure ratings, internal finishes, and external cladding—to integrate seamlessly into your existing infrastructure. This bespoke approach ensures not just a fit, but the optimal solution for your complex water storage needs, maximizing efficiency and minimizing installation complexities.

Robust Stainless Steel Construction as a Pressure Vessel

The integrity and longevity of any large-scale industrial tank begin with its material and construction. This **stainless steel water storage tank** is fabricated from high-grade stainless steel (typically SUS304 or SUS316L, based on the application’s chemical compatibility and pressure requirements). Stainless steel offers exceptional corrosion resistance, crucial for long-term water storage, and is inherently hygienic, preventing contamination. Importantly, this tank is designed as a pressure vessel, meaning it’s built to safely contain liquids under specified pressures, adhering to stringent engineering standards (such as ASME, where applicable). This robust construction ensures not only durability and safety but also compliance with industrial regulations, even in demanding environments.

Hygienic Design & Long-Term Reliability

Maintaining water purity is paramount in industrial settings. The internal surfaces of our stainless steel tanks are meticulously finished (often polished to a sanitary grade) to prevent microbial adhesion and facilitate thorough Cleaning-in-Place (CIP) processes. This hygienic design is crucial for industries like food & beverage, pharmaceuticals, and manufacturing, where product quality and safety depend on uncontaminated water. The tank’s durable stainless steel material, combined with expert welding and fabrication, ensures a significantly extended service life with minimal maintenance, providing a reliable and cost-effective asset for your long-term water storage infrastructure.

Paramètres du produit

The Stark Water Industrial Customized 10000 Gallon Stainless Steel Water Storage Tank, designed as a pressure vessel, is built to precise industrial specifications. Here are its typical and customizable technical parameters:

| Paramètres | Spécifications / Options de personnalisation |

|---|---|

| Capacité | 10000 Gallons (approx. 37,854 Liters / 37.85 m³) – Customizable to various large capacities. |

| Concentration sur les mots-clés essentiels | 10000 Gallon Stainless Steel Water Storage Tank et de ses capacités. |

| Construction matérielle | High-grade Stainless Steel (SUS304, SUS316L, Duplex SS; specified by client for chemical compatibility, temperature, and pressure). |

| Type de conception | Vertical or Horizontal, Cylindrical, with dished or conical ends (torispherical, elliptical, conical heads). |

| Design Standard | Designed and manufactured as a Pressure Vessel, adhering to standards like ASME Boiler and Pressure Vessel Code, EN 13445, PED, TEMA (if heat exchanger type), ISO, etc., as required. |

| Finition de la surface interne | Sanitary polished (e.g., Ra < 0.6 μm, or Ra < 0.4 μm for aseptic/high-purity applications); electro-polishing available. |

| Finition de la surface extérieure | Satin polished, Matt finish, #2B finish, or painted. |

| Pression de fonctionnement max. Pression de fonctionnement | Customizable to specific industrial process pressure requirements (e.g., 0.5 MPa to 1.0 MPa, or higher). |

| Max. Operating Temperature | Customizable, designed for specific hot or cold water storage (e.g., -20°C to 150°C). |

| Isolation (en option) | Polyurethane Foam, Mineral Wool, or Fiberglass with stainless steel, aluminum, or painted carbon steel cladding. |

| Jacket (Optional) | Dimple, Coil, or Full Jacket for precise heating or cooling applications. |

| Agitation (Optional) | Top or side-mounted agitators with various impeller types for mixing. |

| Connexions/raccords |

|

| Support Type | Skirt support, leg support, or lug support. |

| Testing & Certification | Hydrostatic testing, NDT (Non-Destructive Testing), material test reports, compliance certificates (e.g., ASME U Stamp, PED, CE, upon request). |

Industrie concernée

The Stark Water Industrial Customized 10000 Gallon Stainless Steel Water Storage Tank, as a pressure vessel, is a critical asset for large-scale industrial operations requiring robust, hygienic, and safe storage of water or other liquids under pressure or specific thermal conditions. Its customizable nature makes it invaluable for a diverse range of industries, including:

- Industrie alimentaire et des boissons : Storing large volumes of process water, purified water (post-RO/UF), ingredient water, or finished liquid products, often under hygienic conditions and precise temperature control.

- Pharmaceutical & Biotechnology: Essential for storing Purified Water (PW), Water for Injection (WFI), sterile solutions, and buffer preparations, adhering to stringent GMP and regulatory requirements for purity and containment.

- Chemical Processing: Holding large quantities of process water, chemical solutions, solvents, or reaction intermediates, especially when pressure containment, corrosion resistance, or temperature control is crucial.

- Power Generation: Storing treated boiler feed water, condensate, or cooling tower make-up water, ensuring a reliable supply for critical plant operations and protecting equipment.

- Electronics & Semiconductor Manufacturing: Storing ultra-pure water (UPW) used in high-tech manufacturing processes, where massive volumes of ultrapure water are constantly required.

- Wastewater Treatment Plants: Utilized as large buffer tanks for treated effluent or process water within the plant, especially for industrial wastewater streams.

- Pulp & Paper Industry: Storing process water, chemical solutions, or wastewater in large volumes under demanding conditions.

- Mining & Metals Industry: Storing process water, slurries, or treated water for various stages of mineral processing.

- Municipal Water Treatment Plants: Large buffer tanks for treated drinking water or for specific process stages within the treatment facility.

- Oil & Gas Industry: Storing produced water, frac fluids, or treated water for various processes, often requiring robust pressure ratings.

Avantage 1

Avantage DEUX

Produits apparentés

Produits similaires

-

Équipement d'ultrafiltration

Équipement d'ultrafiltration 15T Systèmes industriels d'UF

Ajouter au devis

FAQ

Q1 : Quelle est la durée de vie du système d'osmose inverse ?

La durée de vie d'un système d'osmose inverse dépend de la qualité de l'eau et de l'entretien. En règle générale, la membrane dure 2 à 3 ans, tandis que le système lui-même peut durer plus de 10 ans s'il est bien entretenu.

Q2 : Le système peut-il être personnalisé en fonction des différentes conditions de l'eau ?

Oui, tous nos systèmes sont entièrement personnalisables. Nous analysons vos besoins en matière de rapports sur l'eau et d'applications avant de vous proposer des solutions sur mesure.

Q3 : Quelles sont les normes auxquelles répondent les équipements STARK ?

Nos produits sont conformes aux normes CE et ISO 9001 et peuvent être conçus pour répondre à des réglementations régionales spécifiques ou à des normes industrielles sur demande.

Q4 : Quel est le délai de livraison des systèmes STARK RO ?

Les systèmes standard sont expédiés dans un délai de 7 à 15 jours. Pour les commandes personnalisées, le délai peut aller jusqu'à 20-25 jours en fonction de la complexité.

Q5 : Fournissez-vous une assistance technique ou des conseils d'installation ?

Oui. Nous fournissons une documentation technique complète, des conseils à distance par vidéo et nous pouvons envoyer des ingénieurs à l'étranger sur demande.

Q6 : Qu'est-ce qui est inclus dans votre devis ?

Notre devis comprend le système RO complet, le panneau de contrôle, les pompes, les unités de prétraitement et tous les accessoires nécessaires. Les outils d'installation et les pièces de rechange peuvent être inclus sur demande.