Reading time: 14–18 minutes · Penonton: water treatment engineers, plant operators, EPC designers, distributors

Executive summary: Ini water treatment FAQ collects the questions experienced engineers hear every day in industrial projects: What standards apply to tap water? How should pH, conductivity and TDS be interpreted? What exactly does a “security filter” protect? When should you use ion exchange, and when is RO enough? This guide explains the concepts in practical language so you can answer customer questions, design systems more confidently and avoid common misunderstandings in the field.

1. Basic Standards and Water Quality Concepts

Q1. What are the key standards for municipal drinking water quality?

Every country or region has its own drinking-water regulation, but they share a similar structure: a list of microbiological, toxicological and aesthetic parameters with maximum allowable limits. In China, for example, the current national standard GB 5749 includes more than 80 indicators such as E. coli, turbidity, color, odor, heavy metals, organic micro-pollutants and disinfection by-products.

Municipal water utilities are responsible for meeting these limits at the outlet of the water treatment plant or at defined points in the distribution system. However, these standards are written for public health at the tap, not for the specific needs of industrial processes or high-purity applications.

Q2. How do industrial pure-water specifications differ from tap water?

Industrial users often go far beyond drinking-water criteria. Typical additional or tightened requirements include:

- Conductivity / resistivity: boiler feed and electronics manufacturing may require conductivity below 1 μS/cm or resistivity above 10–18 MΩ·cm.

- Hardness: boilers, cooling towers and many processes demand nearly zero calcium and magnesium to prevent scale.

- Silika: for high-pressure boilers and ZLD systems, silica is strictly limited to avoid turbine deposits and silica scaling.

- TOC and bacteria: pharmaceutical, food & beverage and ultrapure water systems specify tight limits on organics and microbiology.

That is why most industrial projects add dedicated water treatment equipment downstream of municipal supply, even when tap water already meets local drinking standards.

2. pH, Conductivity, Resistivity and TDS — Getting the Numbers Right

Q3. How should I correctly interpret pH test strips and pH values?

pH test strips are convenient for quick checks but have limited precision (often ±0.5 units). When using them:

- Immerse the strip for the time specified by the manufacturer; do not over-immerse or shake violently.

- Compare the color with the chart immediately under good lighting; colors can drift if you wait too long.

- Use strips for trend checks (for example, confirming whether pH is roughly 6, 7 or 8), not for tight control.

Whenever dosing chemicals, adjusting RO pH or verifying compliance with specifications, a calibrated pH meter with temperature compensation is far more reliable than strips.

Q4. What are conductivity and resistivity, and how are they related?

Konduktivitas measures how easily water conducts electricity and is expressed in μS/cm or mS/cm. It reflects the total concentration of dissolved ions. Resistivity is the opposite concept — how strongly water resists electrical flow — and is usually expressed in MΩ·cm in pure-water systems.

The two are mathematical inverses, but you must keep units consistent:

- If conductivity κ is given in μS/cm, convert to S/cm (divide by 1,000,000), then resistivity ρ (in Ω·cm) is ρ = 1/κ.

- For pure water, operators commonly use MΩ·cm. In that case ρ(MΩ·cm) ≈ 1,000,000 / κ(μS/cm).

For example, a conductivity of 0.1 μS/cm corresponds to roughly 10 MΩ·cm. Understanding this relationship is essential when customers ask for “18 MΩ cm pure water” or when you are reading instrument specifications in this water treatment FAQ.

Q5. What is TDS and how does it relate to conductivity?

Total Padatan Terlarut (TDS) represents the mass of dissolved inorganic and organic substances in water, usually expressed in mg/L or ppm. It includes major ions such as calcium, magnesium, sodium, potassium, chloride, sulfate and bicarbonate, as well as smaller contributions from other species.

In many field applications, TDS is estimated from conductivity using an empirical factor:

- For typical groundwater or tap water, TDS (mg/L) ≈ 0.5–0.8 × conductivity (μS/cm).

- The exact factor depends on ion composition; seawater, brackish water and certain wastewaters deviate from these simple rules.

For engineering calculations and guarantees, it is safer to use laboratory-measured TDS and ion analyses rather than relying only on generic conductivity–TDS conversion factors.

3. Pretreatment and Cartridge Filters

Q6. What types of filter cartridges are used in security filters and fine filters?

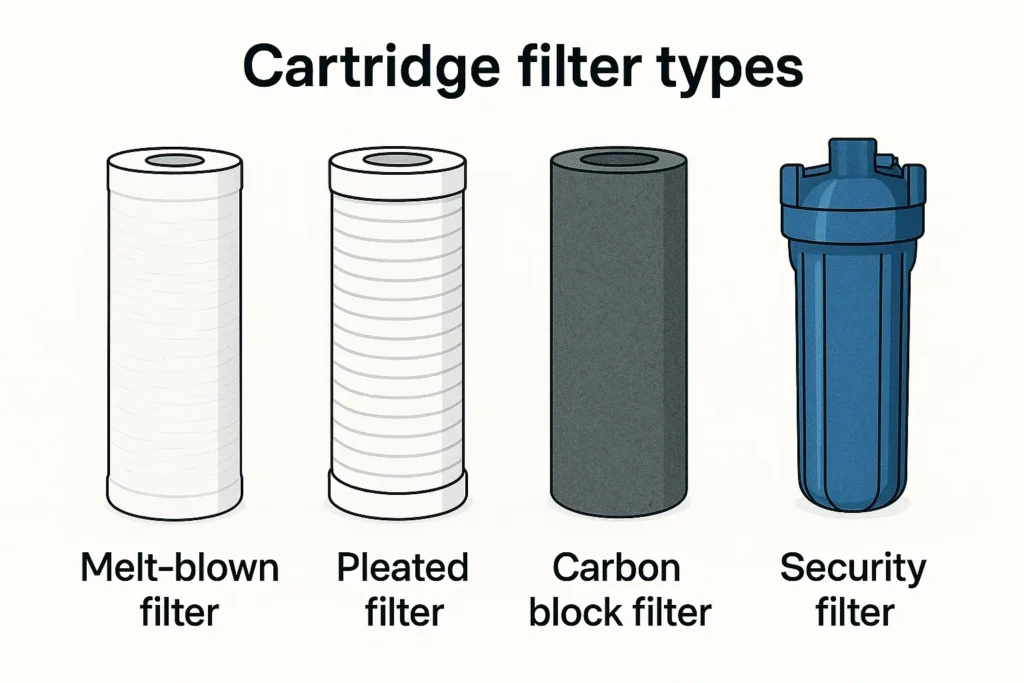

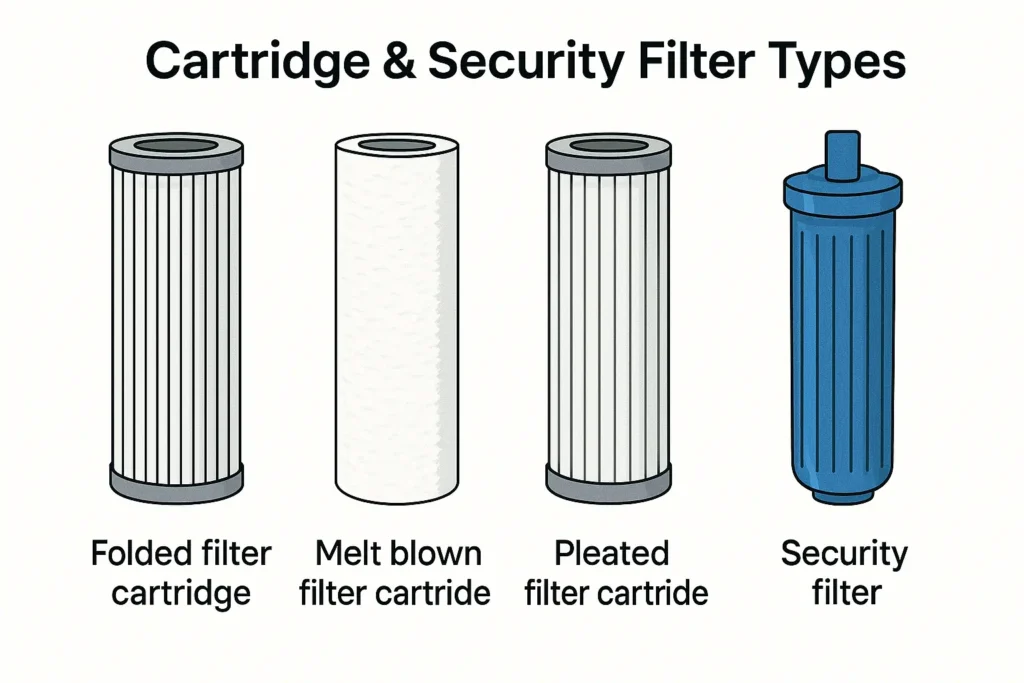

Cartridge filters are the last barrier before high-pressure pumps and membranes. Common cartridge types include:

- PP melt-blown cartridges: depth-type filters with gradually tightening pore structure. They are inexpensive and widely used for 1–20 μm ratings.

- String-wound cartridges: yarn wound around a core; suitable for high-load, coarse filtration in some industries.

- Granular or block activated carbon cartridges: used to remove residual chlorine, organic compounds, color and odor; they must be placed ahead of RO membranes to protect polyamide from oxidation.

- Microporous membrane cartridges: pleated membranes with absolute ratings such as 0.22, 0.45 or 1 μm for critical polishing before ultrapure applications.

Q7. What is the role of the “security filter” in an RO system?

The security filter sits after multi-media and activated carbon filters and just before the high-pressure pump. Its job is to catch any remaining suspended solids, resin fragments or filter media that might have escaped upstream units. By doing so, it protects:

- High-pressure pump impellers and seals from abrasion or blockage.

- RO membrane feed channels from being plugged by coarse particles.

Security filters are typically rated at 5 μm nominal, with pressure-drop monitoring. When the pressure difference between inlet and outlet exceeds the design limit (for example, 0.08–0.10 MPa), cartridges should be replaced.

Q8. How do I quickly size security filter cartridges for flow rate?

A practical rule of thumb used by many engineers is:

One 20-inch 5 μm cartridge can handle about 1 m³/h of relatively clean feedwater.

Based on this rule, a 10 m³/h RO system would start with around 10 cartridges. In real projects you should adjust this number according to actual SDI, turbidity and fouling tendency, and always leave some margin. If the system frequently exhibits high pressure drop across the security filter, either the pretreatment is insufficient or more cartridges are needed.

4. Ion Exchange Demineralization — When RO Is Not Enough

Q9. How does an ion exchange pure-water system actually work?

An ion exchange pure-water system removes dissolved salts through reversible ion-exchange reactions. A typical train looks like this:

- Multi-media (sand) filter: removes suspended solids to protect downstream equipment.

- Activated carbon filter: removes residual chlorine and organic compounds that could damage resins.

- Cation exchanger: exchanges Ca²⁺, Mg²⁺, Na⁺ and other cations for H⁺, producing acidic effluent with mainly H⁺ and anions.

- Anion exchanger: exchanges Cl⁻, SO₄²⁻, NO₃⁻ and others for OH⁻, combining with H⁺ to form water.

- Mixed bed (polishing): a mixture of cation and anion resins that produces very low conductivity water, often ≤0.1 μS/cm.

- Final polishing cartridge: ultrafine filtration to remove any resin fines or particulates before use.

During regeneration, acids and caustic are used to restore resins to their original ionic form. Proper segregation, neutralization and safety procedures are essential.

Q10. When should I choose ion exchange vs. RO, or RO plus mixed bed?

Both RO and ion exchange can produce demineralized water, but they have different strengths:

- RO alone is often ideal when feed TDS is high and a conductivity of 5–20 μS/cm is sufficient (for example, general industrial process water, many cooling applications).

- Ion exchange alone may be attractive when feed TDS is relatively low and chemicals are inexpensive, but it requires handling regeneration chemicals and waste streams.

- RO + mixed bed is a common combination for high-purity water: RO removes most salts and organics, while a small mixed bed polisher boosts resistivity to 10–18 MΩ·cm with much lower chemical consumption than a full resin train.

When customers ask in a meeting from this water treatment FAQ, the short answer is: use RO for bulk desalination, and add ion exchange only when the specification demands very low conductivity or specific ion removal that RO cannot guarantee alone.

5. RO Systems and Pure-Water Machines

Q11. What pretreatment does an RO system need to run reliably?

RO membranes are efficient but sensitive. To keep them running smoothly, most suppliers recommend feedwater conditions similar to:

- SDI (silt density index) < 4, preferably < 3.

- Turbidity < 1 NTU.

- Residual chlorine < 0.1 mg/L (polyamide membranes are easily oxidized).

- Iron < 0.01–0.05 mg/L and low manganese to prevent fouling and staining.

- Temperature between 10 and 30 °C, within the membrane’s rating.

- Scaling indices (LSI, etc.) within recommended limits, supported by antiscalant dosing when necessary.

In practice, this means using properly designed multi-media filters, carbon filters, cartridge filters and chemical dosing systems ahead of the RO skid.

Q12. What are the main components of an RO pure-water machine?

A standard RO pure-water system includes:

- Raw-water pump and storage tank (if pressure or flow from supply is unstable).

- Pretreatment units such as multi-media filters, carbon filters, softeners and security filters.

- High-pressure pump that provides the driving force for reverse osmosis.

- RO membrane modules and pressure vessels, typically 4040 or 8040 spiral-wound elements arranged in stages.

- Automatic flushing and cleaning system to rinse membranes and perform CIP when required.

- Instrumentation and controls including flow meters, pressure gauges, conductivity meters and PLC/HMI for automation.

Q13. How does the typical RO pure-water process flow look from raw water to product water?

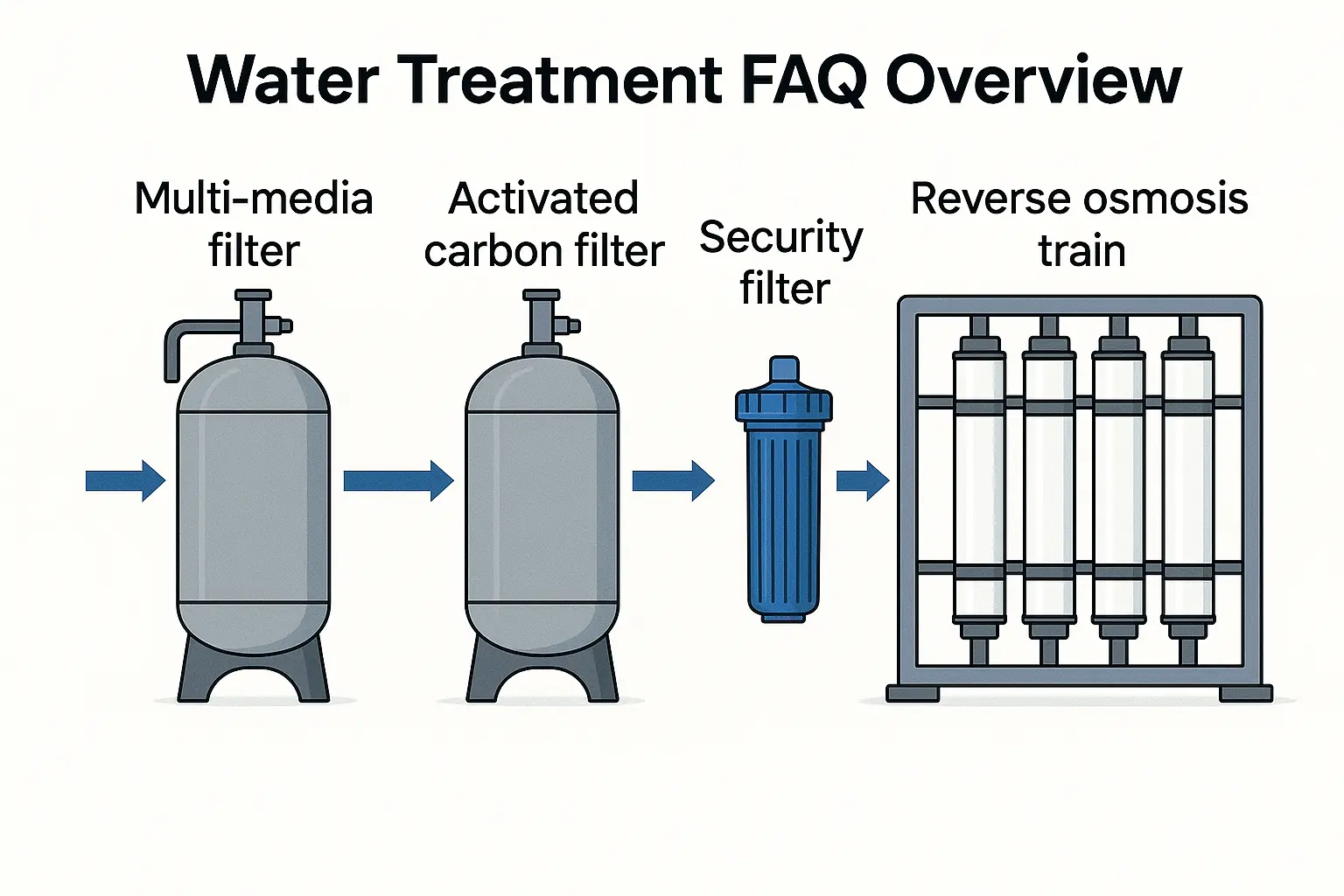

A simple single-pass RO flow can be described as:

- Raw water enters a multi-media filter to remove suspended solids.

- It then passes through an activated carbon filter to remove chlorine and organic compounds.

- Chemicals such as antiscalant, pH adjuster or sodium bisulfite are dosed as needed.

- The water flows through a security filter (cartridge housing) to catch any remaining particulates.

- A high-pressure pump boosts pressure into the RO membrane train, producing permeate and brine.

- Meresap is sent to a pure-water tank, and air garam can be discharged or reused for low-grade purposes such as washing or irrigation, depending on quality and regulations.

Many projects add a second RO pass, mixed-bed polisher or EDI system after the first pass when higher purity is required.

6. Raw-Water Pretreatment — Why It Matters

Q14. What are the typical units in raw-water pretreatment?

Pretreatment is the unsung hero of reliable RO and ion exchange operation. Typical units include:

- Multi-media (mechanical) filter: removes suspended solids and part of the colloidal load using layers of quartz sand, anthracite and garnet.

- Activated carbon filter: adsorbs chlorine, chloramine, organic color and odorous compounds, protecting both resins and membranes.

- Security filter (cartridge housing): the final barrier before high-pressure equipment, as described earlier in this water treatment FAQ.

Q15. Why do we often add coagulant before the multi-media filter?

Many raw waters contain fine colloids and natural organic matter that are difficult to remove by filtration alone. Low-dose coagulant (for example, aluminum or iron salts, or polymeric coagulants) is added before the multi-media filter to destabilize these colloids and form larger flocs.

Benefits of proper coagulation include:

- Lower SDI and turbidity entering the RO system.

- Longer filter backwashing intervals and membrane cleaning intervals.

- Reduced fouling risk in downstream cartridges, RO membranes and ion exchange beds.

Coagulant dosing should always be optimized by jar testing and monitored carefully; overdosing can increase sludge generation and contribute to fouling if not properly controlled.

7. Quick Reference — Rules of Thumb and Field Tips

This section summarizes a few practical tips from the industrial water treatment FAQ that engineers often use in the field:

- Security filter sizing: as a first estimate, one 20″ 5 μm cartridge can treat about 1 m³/h of relatively clean water; adjust based on SDI and fouling observations.

- RO recovery and brine reuse: many single-pass RO systems operate at 60–80 % recovery. The brine, although more saline, is usually cleaner than the raw water and may be reused for non-critical applications if local regulations allow.

- Instrumentation priority: for high-purity systems, online conductivity or resistivity is more informative than TDS; for surface-water pretreatment, turbidity and SDI are key early-warning indicators.

- Dokumentasi: when troubleshooting, record feed, permeate and concentrate conductivity, pH, flow and pressure together; isolated single readings rarely tell the full story.

8. How to Use This Water Treatment FAQ in Your Project

For sales engineers, designers and operators, this water treatment FAQ can serve as a shared reference when discussing requirements with customers or colleagues. You can:

- Use the questions as a checklist during project kick-off meetings to ensure key topics are not missed.

- Adapt the answers into training material for new operators or technicians.

- Combine this FAQ with project-specific water analyses and process diagrams to build a customized operation manual.

For deeper dives into particular topics, explore the related guides below.

Further Reading & Related Guides

- Solusi Pengolahan Air Industri

- RO and High-Purity Water Systems

- More Technical Articles & Water Treatment Guides

- Stark Water Tools — Online Calculators and Sizing Aids

- WHO — Drinking-water Quality and Health

- US EPA — Ground Water and Drinking Water Resources

Next Steps — Need Help With Your Water Treatment Project?

If you are planning a new system or troubleshooting an existing one and want advice beyond this water treatment FAQ, a short engineering review can quickly clarify options and risks. Share your raw-water analysis, required flow and target quality, and our team can suggest a practical treatment train and budget range.

Minta Penawaran or contact us to discuss your application.