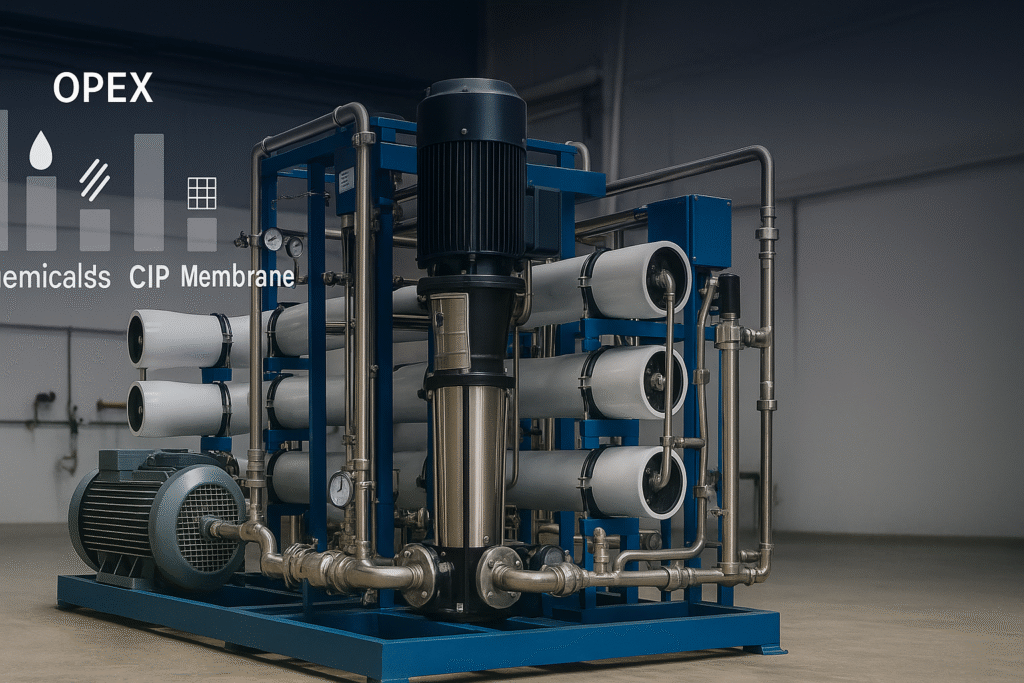

Apa yang termasuk dalam kalkulator RO OPEX ini (tampilan bulanan)

Ini Kalkulator RO OPEX memperkirakan biaya operasi skid reverse osmosis skala kecil hingga menengah setiap bulannya. Ini memecah OPEX menjadi enam bagian: energi, bahan kimia (antiscalant dan-jika ada-SMBS untuk deklorinasi, asam/alkali untuk kontrol pH dan CIP), filter kartrid, frekuensi CIP (bahan kimia + tenaga kerja/waktu henti), amortisasi membran, dan jalur "lain-lain". Hasil membantu Anda membuat tolok ukur biaya per m3 dan mengidentifikasi pengungkit terbesar untuk dioptimalkan.

Cara menggunakan kalkulator RO OPEX

- Tentukan produksi: set Aliran rembesan (LPH), jam/hari dan hari/bulan. Alat ini mengonversi ke m³ bulanan.

- Masukkan intensitas energi (kWh/m³) dan tarif lokal. For brackish RO, realistic ranges are ~0.7–1.2 kWh/m³ at 8–16 bar (site-dependent).

- Bahan kimia: use typical antiscalant dose (e.g., 2–5 mg/L) and local $/kg. If you dechlorinate, add SMBS dose and price. If you regulate pH or CIP chemistry, include those in the CIP cost lines.

- Cartridge filters: enter the number of filters consumed per month and the unit price. Pretreatment quality and SDI drive this number.

- CIP frequency: enter average CIPs/month, plus chemical cost and labor/downtime cost per CIP. Well-designed brackish systems often run 3–6 months between CIPs.

- Membrane amortization: set the membrane set price and expected lifetime (months). The calculator spreads the cost across the lifetime.

Interpreting results & typical ranges

- Energi usually dominates at small scale. Improving pump/VFD efficiency and realistic recovery targets have outsized impact.

- Chemicals grow with higher recovery and challenging feed (TDS/SDI/temperature). Proper antiscalant selection and dosing control reduce waste.

- Filters are a proxy for pretreatment performance. If filters spike, review SDI trending, MMF/UF condition, and upset protection.

- CIP frequency is the tell: rising CIP cadence indicates a recovery target or pretreatment issue and pushes up OPEX and downtime.

- Membrane amortization falls with longer life; good pretreatment and conservative operating windows lower lifecycle cost.

Worked example (1000 LPH brackish RO)

Assume 1000 LPH, 10 h/day, 26 days/month ⇒ 260 m³/month; energy 1.0 kWh/m³ at $0.11/kWh; antiscalant 3 mg/L at $4/kg; four 30″ cartridges/month at $12/pc; CIP every 4 months (0.25/month) with $60 chemicals and $40 labor; membrane set (2×4040) $600 with 24-month life. The calculator yields a total OPEX on the order shown in the table above and a cost per m³ in the $0.4–0.7 range under stable pretreatment. Your site values will vary.

Ways to reduce OPEX without hurting reliability

- Target a realistic recovery for your TDS/temperature/SDI; pushing recovery too high increases scaling risk and CIP frequency.

- Stabilize with UF or better pretreatment when SDI > 3 or turbidity is variable; this improves flux stability and filter life.

- Instrument conductivity, pressure and flow online; use trending to detect drift early and schedule maintenance before efficiency losses stack up.

- Gunakan vendor-recommended element operating windows and seasonal set-points to avoid unnecessary pressure/energy penalties.

Sumber daya terkait

• Reference solution with architecture, KPIs and selection guides:

Solusi Pengolahan Air RO 1000 LPH.

• Example hardware starting point:

1000 L Reverse Osmosis System.

• Electricity tariff data (external):

U.S. EIA – Electricity.

• Drinking-water quality guidance (external):

WHO Guidelines for Drinking-water Quality.

FAQ – RO OPEX calculator

Apa saja yang termasuk dalam OPEX di sini?

Energy, antiscalant and optional SMBS/pH chemicals, cartridge filters, CIPs (chemicals + labor/downtime), membrane amortization and an “other” bucket for site-specific items.

Berapa jumlah energi yang harus saya rencanakan?

For brackish RO, plan roughly 0.7–1.2 kWh/m³ at 8–16 bar. Salinity, temperature and recovery shift this range.

Bagaimana cara memilih dosis antiscalant?

Start with vendor software and your target recovery. Typical ranges are 2–5 mg/L for brackish feeds; verify against your ions and operating window.

Seberapa sering CIP masuk akal?

With solid pretreatment and realistic recovery, many small plants run 3–6 months between CIPs. Rising CIP cadence is a signal to revisit pretreatment or recovery.

Apakah masa pakai membran sangat memengaruhi OPEX bulanan?

Yes. Spreading a membrane set over 24–36 months meaningfully lowers $/m³. Proper pretreatment and conservative operation extend life.