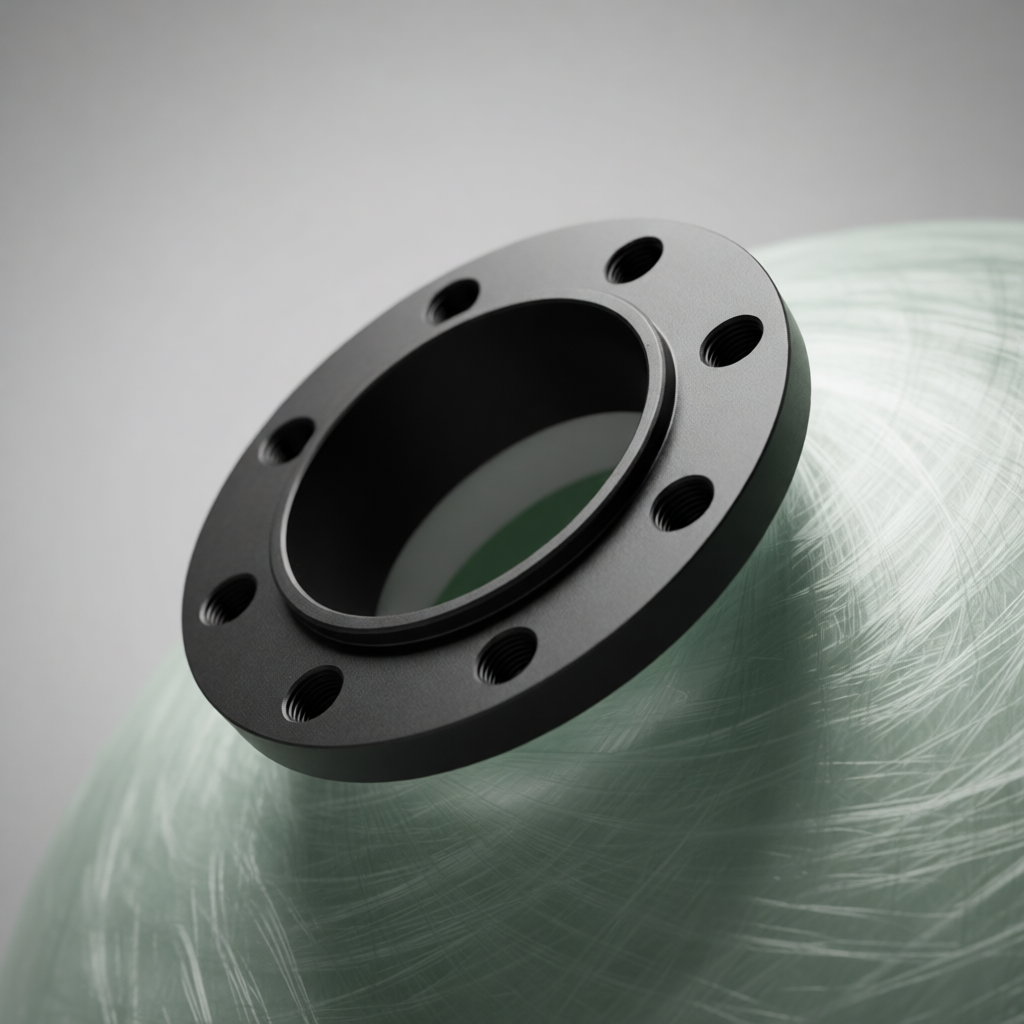

Stark Industrial 6″ Flange Pressure Vessel Series (Heavy Duty)

The Stark industrial **6″ Flange pressure vessel** is engineered for high-volume filtration applications. Featuring a secure 6-inch flange top opening, this heavy-duty tank series (36″-72″ diameter) is designed for municipal water treatment and large-scale industrial plants requiring maximum flow rates and absolutely leak-proof pipe connections.

Deskripsi Produk

Engineered for the Toughest Industrial Demands.

The Stark **6″ Flange pressure vessel** series represents the pinnacle of large-scale composite manufacturing. Unlike threaded connections which can be prone to leaks under the stress of large piping systems, our 6-inch flange interface offers a robust, bolted connection point compatible with standard DN150 industrial piping. This ensures zero-leakage performance even under high vibration or pressure surges common in desalination plants and municipal facilities.

Our proprietary multi-axis winding process ensures that even our largest 72-inch vessels maintain structural rigidity and uniform pressure distribution, offering a superior, corrosion-resistant alternative to rubber-lined steel tanks.

Installation & Standard Data:

Proper flange alignment and bolt torque are critical for large vessel safety. For detailed flange dimension drawings (ANSI/DIN), bolt circle specifications, and installation torque guides, please reference the technical documentation at our specialized manufacturing division:

Stark Tank Manufacturing – 6″ Flange Series Technical Specs

.

Parameter Produk

Below are the verified specifications for our 6″ Flange top-mount series. These heavy-duty tanks are designed for industrial applications requiring high flow rates.

| Model | Volume Capacity | Dimensions (Dia x H) | Flow Rate (m³/h) | B2B Quote | ||

|---|---|---|---|---|---|---|

| Jenis | US Gal | Liters | Nominal | mm | (Filter/Softener) | Action |

| STK-3694 | 318.4 | 1205 | 36″ x 94″ | Ø900 x 2465 | 7.6-10 / 12-19 | Inquiry |

| STK-4094 | 351.9 | 1332 | 40″ x 94″ | Ø1000 x 2430 | 9.4-11.7 / 15.7-23.5 | Inquiry |

| STK-4272 | 290.6 | 1100 | 42″ x 72″ | Ø1080 x 1850 | 15-25 / 26-30 | Inquiry |

| STK-4872 | 345.6 | 1308 | 48″ x 72″ | Ø1200 x 1880 | 13.5-17 / 22.6-34 | Inquiry |

| STK-4894 | 504.4 | 1909 | 48″ x 94″ | Ø1200 x 2430 | 13.5-17 / 22.6-34 | Inquiry |

| STK-6083 | 570.1 | 2158 | 60″ x 83″ | Ø1500 x 2120 | 21-27 / 35-53 | Inquiry |

| STK-6094 | 710.2 | 2688 | 60″ x 94″ | Ø1500 x 2430 | 21-27 / 35-53 | Inquiry |

| STK-6383 | 681.6 | 2580 | 63″ x 83″ | Ø1600 x 2100 | 25-45 / 46-56 | Inquiry |

| STK-7294 | 940.8 | 3561 | 72″ x 94″ | Ø1800 x 2400 | 30-40 / 50-76 | Inquiry |

*Note: US dimensions are nominal. Flow rates are for reference only. Please consult our engineers for precise system design.

Industri yang Berlaku

- Pengolahan Air Kota:

Large-scale sand and carbon filtration for city water supplies, removing sediment and contaminants at high throughput. - Seawater Desalination:

Pre-treatment filtration for SWRO plants, utilizing corrosion-resistant FRP to withstand aggressive saline environments. - Power Plant Cooling Systems:

Side-stream filtration for cooling towers to reduce suspended solids and prevent heat exchanger fouling.

Keuntungan Satu

Secure Flange Connection

For vessels exceeding 36 inches in diameter, threaded connections are often insufficient. Stark’s 6-inch flange top opening provides a standardized, bolted connection that eliminates the risk of thread stripping or cross-threading during installation.This design allows for the secure attachment of heavy industrial piping (steel or large diameter UPVC) and ensures a reliable seal capable of withstanding system vibration and hydraulic shock.Keuntungan DUA

Massive Capacity, Minimal Maintenance

With diameters up to 72 inches, these vessels hold thousands of liters of media, allowing for extended service runs between backwashes. Unlike traditional rubber-lined steel tanks, Stark FRP vessels are inherently rust-proof and require zero painting or lining maintenance.This significantly reduces the total cost of ownership (TCO) for large-scale projects while providing a service life that often exceeds 10 years in harsh conditions.Produk Terkait

Produk Terkait

PERTANYAAN YANG SERING DIAJUKAN

T1: Berapa lama sistem reverse osmosis bertahan?

Umur dari sistem reverse osmosis tergantung pada kualitas air dan pemeliharaan. Biasanya, membran bertahan selama 2-3 tahun, sedangkan sistem itu sendiri dapat bertahan lebih dari 10 tahun dengan perawatan yang tepat.

T2: Dapatkah sistem disesuaikan berdasarkan kondisi air yang berbeda?

Ya, semua sistem kami dapat disesuaikan sepenuhnya. Kami menganalisis laporan air dan kebutuhan aplikasi Anda sebelum memberikan solusi yang disesuaikan.

T3: Standar apa yang dipatuhi oleh peralatan STARK?

Produk kami memenuhi CE, ISO 9001, dan dapat dirancang untuk memenuhi peraturan regional atau standar industri tertentu berdasarkan permintaan.

T4: Berapa waktu pengiriman untuk sistem STARK RO?

Sistem standar dikirim dalam waktu 7-15 hari. Untuk pesanan yang disesuaikan, waktu tunggu dapat diperpanjang hingga 20-25 hari tergantung pada kerumitannya.

T5: Apakah Anda menyediakan dukungan teknis atau panduan pemasangan?

Ya. Kami menyediakan dokumentasi teknis lengkap, panduan jarak jauh melalui video, dan dapat mengirimkan teknisi secara internasional berdasarkan permintaan.

T6: Apa saja yang termasuk dalam penawaran Anda?

Kutipan kami mencakup sistem RO lengkap, panel kontrol, pompa, unit pra-perawatan, dan semua perlengkapan yang diperlukan. Alat instalasi dan suku cadang dapat disertakan berdasarkan permintaan.