STARK 4040/8040 Housing Membran Ro Baja Tahan Karat

STARK 4040/8040 Housing Membran Ro Baja Tahan KaratSTARK 4040/8040 Housing Membran Ro Baja Tahan Karat

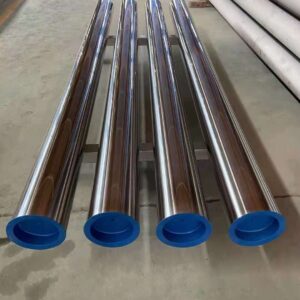

Secure robust and reliable containment for your RO membranes with Stark Water’s STARK 4040/8040 Stainless Steel RO Membrane Housing. This durable stainless steel ro membrane housing is designed to precisely fit both 4040 and 8040 RO elements, providing secure, leak-proof performance crucial for various industrial and commercial reverse osmosis systems.

Deskripsi Produk

The integrity and efficiency of any Reverse Osmosis (RO) system are fundamentally dependent on the quality of its membrane housing, a critical pressure vessel responsible for containing and protecting the RO membrane elements. The Stark Water STARK 4040/8040 Stainless Steel RO Membrane Housing is meticulously engineered to deliver exceptional durability, reliability, and versatile performance for a wide array of industrial and commercial RO applications. This housing stands as a testament to superior engineering, ensuring the longevity and optimal function of your water purification infrastructure.

Versatile Compatibility for 4040 and 8040 RO Membranes

A key strength of this product is its versatile compatibility, designed to perfectly accommodate both standard 4040 RO membrane elements (4-inch diameter, 40-inch length) and 8040 RO membrane elements (8-inch diameter, 40-inch length). This dual compatibility makes our stainless steel ro membrane housing an incredibly flexible choice for system designers and operators. Whether you are building a smaller-scale commercial RO unit or a large industrial purification plant, this housing provides the precise fit required, preventing bypass of untreated water and maximizing the efficiency of the reverse osmosis process across different system capacities.

Unmatched Durability with Stainless Steel RO Membrane Housing Construction

Safety, longevity, and corrosion resistance are paramount for any pressure-bearing component in water treatment. Our stainless steel ro membrane housing is constructed exclusively from high-grade stainless steel (typically SUS304 or SUS316L, depending on the application’s specific requirements for corrosion resistance). This material choice provides exceptional resilience against aggressive water chemistries, corrosive industrial environments, and the high operating pressures (ranging from 200-1200 PSI or more for brackish and seawater applications) inherent in efficient reverse osmosis. The robust construction ensures a significantly extended operational lifespan, mitigating the risk of leaks or catastrophic failures and providing a secure containment solution for your valuable RO membranes.

Reliable, Leak-Proof Design for Consistent Purity

A hallmark of the Stark Water 4040/8040 stainless steel membrane housing is its robust and leak-proof design. Precision manufacturing techniques, combined with high-quality sealing components (such as durable O-rings), ensure an absolutely sealed environment under all operating conditions. This critical design feature prevents any untreated feedwater from bypassing the RO membranes and contaminating the purified water stream, thereby guaranteeing consistently high-quality permeate. This reliability contributes directly to maintaining the purity of your final product and the integrity of your downstream processes, ensuring peace of mind in your water purification operations.

Simplified Installation and Long-Term Value

Designed with practical industrial application in mind, our stainless steel membrane housing facilitates straightforward installation and routine maintenance. Its robust build and high-quality materials significantly reduce the need for frequent replacements or repairs, contributing to lower long-term operational costs. By providing superior protection for your sensitive RO membranes and ensuring efficient flow dynamics, our stainless steel ro membrane housing effectively extends the lifespan of your entire RO system, offering excellent value and dependable performance throughout its service life.

Parameter Produk

The STARK 4040/8040 Stainless Steel RO Membrane Housing is engineered for robust and reliable performance with both 4040 and 8040 RO membrane elements. Here are its key technical specifications:

| Parameter | Opsi Spesifikasi / Kustomisasi |

|---|---|

| Fokus Kata Kunci Inti | stainless steel ro membrane housing design and capabilities. |

| Compatible Membrane Sizes | 4040 (4-inch diameter x 40-inch length) and 8040 (8-inch diameter x 40-inch length) RO Membrane Elements. Available for 1 to 7+ elements per vessel, depending on size. |

| Konstruksi Material | Stainless Steel (SUS304 or SUS316L, specific grade chosen based on application and water chemistry). |

| Maks. Tekanan Operasi | Typically 300 PSI, 450 PSI, 600 PSI, or higher (e.g., 1000 PSI, 1200 PSI for seawater RO). |

| Jenis Desain | End-entry or Side-entry ports. Multi-port options (e.g., 2.5″, 4″ side ports for 8040). |

| Koneksi Port | Threaded (NPT/BSP), Flanged (ANSI/DIN), or Victaulic connections. |

| Jenis Tutup Ujung | Quick-Lock (clamped), Threaded, or Bolt-on for secure closure and easy membrane replacement. |

| Bahan Penyegel | EPDM, Viton (FKM), or Buna-N (NBR) O-rings, selected based on temperature and chemical compatibility. |

| Permukaan Akhir Internal | Dipoles (misalnya, Ra < 0,6 μm) atau dipoles secara elektro untuk kebersihan dan aliran yang optimal. |

| Permukaan Akhir Eksternal | Satin, Matte, Brushed, or other finishes. |

| Maks. Suhu Pengoperasian | Hingga 49°C (120°F) untuk segel standar; lebih tinggi dengan bahan khusus. |

| Perangkat Keras Pemasangan | Termasuk sadel dan tali pengikat dari baja tahan karat. |

| Pengujian & Sertifikasi | Hydrostatic pressure tested; ASME Boiler and Pressure Vessel Code (Section VIII, Div 1) U-Stamp or CE Mark available upon request. |

Industri yang Berlaku

The STARK 4040/8040 Stainless Steel RO Membrane Housing is a vital and adaptable component for high-performance Reverse Osmosis systems across a diverse range of industrial and commercial sectors. Its robust stainless steel construction and compatibility with common 4040 and 8040 membranes make it indispensable for:

- Industrial Water Treatment Plants: Essential for containing RO membranes in systems providing purified water for manufacturing processes, utility, and general industrial use, such as in chemical plants, food processing facilities, and textile mills.

- Municipal Drinking Water Purification: Used in RO systems that supply potable water for towns and cities, ensuring efficient and reliable purification.

- Seawater & Brackish Water Desalination Facilities: Critical for safely containing RO membranes under high pressures, enabling the efficient conversion of saline water into fresh water for various applications.

- Pharmaceutical & Medical Industry: For RO systems generating high-purity water (PW, WFI pre-treatment) for drug manufacturing, laboratory use, and medical device reprocessing, where hygienic containment is vital.

- Electronics & Semiconductor Manufacturing: Used in RO systems that are part of ultra-pure water (UPW) generation facilities, ensuring precise containment for processes sensitive to contamination.

- Power Generation: Utilized in RO systems providing boiler feed water pre-treatment and cooling tower make-up water in power plants, preventing scaling and corrosion in critical equipment and improving energy efficiency.

- Food & Beverage Industry: For RO systems producing high-purity water for beverage formulation (bottled water, soft drinks, breweries), dairy processing, and food ingredient preparation, where hygienic and durable components are required.

- Wastewater Treatment & Reuse: Applied in RO stages of advanced industrial or municipal wastewater treatment plants, contributing to the production of high-quality effluent suitable for discharge or reuse.

Keuntungan Satu

Keuntungan DUA

Produk Terkait

Produk Terkait

PERTANYAAN YANG SERING DIAJUKAN

T1: Berapa lama sistem reverse osmosis bertahan?

Umur dari sistem reverse osmosis tergantung pada kualitas air dan pemeliharaan. Biasanya, membran bertahan selama 2-3 tahun, sedangkan sistem itu sendiri dapat bertahan lebih dari 10 tahun dengan perawatan yang tepat.

T2: Dapatkah sistem disesuaikan berdasarkan kondisi air yang berbeda?

Ya, semua sistem kami dapat disesuaikan sepenuhnya. Kami menganalisis laporan air dan kebutuhan aplikasi Anda sebelum memberikan solusi yang disesuaikan.

T3: Standar apa yang dipatuhi oleh peralatan STARK?

Produk kami memenuhi CE, ISO 9001, dan dapat dirancang untuk memenuhi peraturan regional atau standar industri tertentu berdasarkan permintaan.

T4: Berapa waktu pengiriman untuk sistem STARK RO?

Sistem standar dikirim dalam waktu 7-15 hari. Untuk pesanan yang disesuaikan, waktu tunggu dapat diperpanjang hingga 20-25 hari tergantung pada kerumitannya.

T5: Apakah Anda menyediakan dukungan teknis atau panduan pemasangan?

Ya. Kami menyediakan dokumentasi teknis lengkap, panduan jarak jauh melalui video, dan dapat mengirimkan teknisi secara internasional berdasarkan permintaan.

T6: Apa saja yang termasuk dalam penawaran Anda?

Kutipan kami mencakup sistem RO lengkap, panel kontrol, pompa, unit pra-perawatan, dan semua perlengkapan yang diperlukan. Alat instalasi dan suku cadang dapat disertakan berdasarkan permintaan.