STARK UF PVDF Serat berongga UF filter air membran membran UltraFiltrasi OEM

STARK UF PVDF Serat berongga UF filter air membran membran UltraFiltrasi OEMSTARK UF PVDF Serat berongga UF filter air membran membran UltraFiltrasi OEM

Achieve superior water purification with Stark Water’s STARK UF PVDF Hollow Fiber UF Membrane Water Filter. This high-performance uf membrane, crafted from durable PVDF, offers exceptional filtration efficiency for various industrial and commercial applications, available for OEM customization to meet your specific needs.

Deskripsi Produk

In the realm of advanced water treatment, the choice of membrane material significantly impacts system performance, longevity, and resistance to challenging feedwater conditions. The Stark Water STARK UF PVDF Hollow Fiber UF Membrane Water Filter represents a leading solution in ultrafiltration technology, distinguished by its premium PVDF (Polyvinylidene Fluoride) construction. This advanced uf membrane is engineered to deliver superior separation efficiency and robust durability, making it an ideal choice for a wide array of demanding industrial and commercial water purification needs.

The Superiority of PVDF in UF Membrane Technology

The defining feature of this product is its high-quality **PVDF (Polyvinylidene Fluoride)** material. PVDF is celebrated in membrane technology for its exceptional properties, which directly translate to superior performance in real-world applications:

- Ketahanan Kimia yang sangat baik: PVDF membranes exhibit remarkable resistance to a broad range of chemicals, including strong acids, bases, and oxidizing agents. This makes them highly suitable for treating aggressive industrial wastewaters or applications where chemical cleaning agents are frequently used.

- High Mechanical Strength: PVDF provides outstanding physical durability, allowing the hollow fibers to withstand higher operating pressures and frequent backwashing cycles without breakage, ensuring a longer lifespan.

- Hidrofilisitas: While inherently hydrophobic, specialized treatment during manufacturing enhances PVDF’s hydrophilicity. This improves its wettability, reduces fouling potential, and ensures stable flux rates during filtration.

- Broad Temperature Tolerance: PVDF membranes can operate efficiently across a wider range of temperatures, offering flexibility in various industrial processes.

This inherent strength and resilience of the PVDF material ensure that our UltraFiltration Membrane delivers consistent, high-quality permeate even in challenging environments where other membrane types might degrade.

High-Efficiency Hollow Fiber UF Membrane Water Filter

The **hollow fiber** configuration further enhances the efficiency and compactness of this uf membrane water filter. Thousands of tiny, porous PVDF tubes are bundled together, providing an expansive surface area within a compact module. This design facilitates efficient filtration, effectively removing suspended solids, turbidity, bacteria, viruses, and protozoa (like Cryptosporidium and Giardia) with high rejection rates. Operating at low transmembrane pressures, these membranes contribute to energy efficiency. Their robust structure supports effective backwashing and air scouring techniques, simplifying cleaning cycles, reducing operational downtime, and significantly extending the membrane’s service life.

OEM Capabilities for Tailored Filtration Solutions

As a specialized **OEM (Original Equipment Manufacturer)**, Stark Water offers extensive customization capabilities for our **UF membrane** products. This means we can supply Ultrafiltration membranes precisely tailored to your specific requirements, including custom module dimensions, connection types, flux rates, and specific potting materials. Whether you are a system integrator, a water treatment project developer, or an equipment manufacturer, our OEM services ensure that you receive membranes that perfectly fit your unique system design, optimize performance, and even carry your own branding. This bespoke approach guarantees seamless integration and optimal efficiency for your filtration solutions.

Parameter Produk

| Parameter | Opsi Spesifikasi / Kustomisasi |

|---|---|

| Fokus Kata Kunci Inti | Uf membrane desain dan performa. |

| Bahan Membran | PVDF (Polyvinylidene Fluoride) – High chemical and mechanical resistance. |

| Jenis Membran | Ultrafiltration (UF) Membrane, Hollow Fiber Configuration. |

| Ukuran Pori-pori | Typically 0.01 μm to 0.1 μm (e.g., 0.02 μm, 0.03 μm), specified based on application. |

| Module Configurations | Standard sizes (e.g., 4-inch, 6-inch, 8-inch diameter and various lengths), custom dimensions available as OEM. |

| Mode Operasi | Aliran luar-dalam atau dalam-ke luar. Dapat dioperasikan dalam mode filtrasi buntu atau aliran silang. |

| Tekanan Operasi | Biasanya 0,05 - 0,2 MPa (0,5 - 2 Bar / 7 - 29 PSI). Operasi tekanan rendah. |

| Tekanan Transmembran Maksimum (TMP) | Dapat disesuaikan, biasanya sekitar 0,3 MPa (3 Bar / 43 PSI). |

| Kisaran pH (Operasi Berkelanjutan) | 2 – 10. |

| Kisaran pH (Pembersihan Jangka Pendek) | 1 – 13 (reflecting PVDF’s excellent chemical resistance). |

| Max. Free Chlorine Tolerance | < 100 ppm (short term); < 1 ppm (continuous) – Higher tolerance than some other UF materials. |

| Suhu Operasi | 5°C - 45°C (41°F - 113°F). |

| Turbidity Reduction | >99% |

| Bacteria/Virus Removal | >99.9999% (log 6 reduction or higher). |

| OEM Design/Customization | Custom module dimensions, connection types, specific potting compounds, private labeling possible. |

Industri yang Berlaku

- Pengolahan & Penggunaan Kembali Air Limbah: Particularly effective in Membrane Bioreactor (MBR) systems for municipal and industrial wastewater treatment, producing high-quality effluent due to PVDF’s resistance to organic fouling and harsh cleaning chemicals.

- Air Proses Industri: Provides clean process water in industries where chemical resistance is crucial, such as chemical manufacturing, textile dyeing, and pulp & paper, for boiler feed, cooling towers, and general utility.

- Reverse Osmosis (RO) Pre-treatment: Offers superior pre-filtration for RO systems, especially when dealing with challenging feedwater that may contain high suspended solids, colloids, or requires aggressive cleaning, protecting sensitive RO membranes from fouling and extending their lifespan.

- Drinking Water Treatment: Essential for municipal waterworks and private water supplies for effective removal of turbidity, suspended solids, bacteria, viruses, and protozoa, providing safe potable water.

- Industri Makanan & Minuman: Used for clarification of juices, wine, beer, and other beverages; process water filtration; and pre-treatment for sterile filtration, especially when frequent chemical cleaning is required.

- Pharmaceuticals & Biotechnology: For purification of process water, pre-filtration for sterile processes, and clarification in bioprocessing, benefiting from PVDF’s chemical compatibility and hygiene.

- Oil & Gas Industry: Applied in produced water treatment, frac water filtration, and other applications where the water may contain oil, suspended solids, or harsh chemicals.

- Metal Finishing Industry: Clarification of process solutions, rinse waters, and wastewater to remove suspended solids and heavy metals, benefiting from chemical resistance.

- Mining Operations: For treating process water and wastewater containing high levels of suspended solids and various minerals.

Keuntungan Satu

Keuntungan DUA

Produk Terkait

Produk Terkait

-

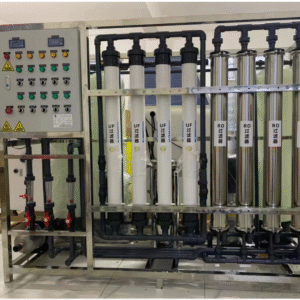

Peralatan ultrafiltrasi

Produsen Peralatan UF Air Sistem Reverse Osmosis ystem Produsen Peralatan UF

Tambahkan ke Kutipan

PERTANYAAN YANG SERING DIAJUKAN

T1: Berapa lama sistem reverse osmosis bertahan?

Umur dari sistem reverse osmosis tergantung pada kualitas air dan pemeliharaan. Biasanya, membran bertahan selama 2-3 tahun, sedangkan sistem itu sendiri dapat bertahan lebih dari 10 tahun dengan perawatan yang tepat.

T2: Dapatkah sistem disesuaikan berdasarkan kondisi air yang berbeda?

Ya, semua sistem kami dapat disesuaikan sepenuhnya. Kami menganalisis laporan air dan kebutuhan aplikasi Anda sebelum memberikan solusi yang disesuaikan.

T3: Standar apa yang dipatuhi oleh peralatan STARK?

Produk kami memenuhi CE, ISO 9001, dan dapat dirancang untuk memenuhi peraturan regional atau standar industri tertentu berdasarkan permintaan.

T4: Berapa waktu pengiriman untuk sistem STARK RO?

Sistem standar dikirim dalam waktu 7-15 hari. Untuk pesanan yang disesuaikan, waktu tunggu dapat diperpanjang hingga 20-25 hari tergantung pada kerumitannya.

T5: Apakah Anda menyediakan dukungan teknis atau panduan pemasangan?

Ya. Kami menyediakan dokumentasi teknis lengkap, panduan jarak jauh melalui video, dan dapat mengirimkan teknisi secara internasional berdasarkan permintaan.

T6: Apa saja yang termasuk dalam penawaran Anda?

Kutipan kami mencakup sistem RO lengkap, panel kontrol, pompa, unit pra-perawatan, dan semua perlengkapan yang diperlukan. Alat instalasi dan suku cadang dapat disertakan berdasarkan permintaan.