As industrial water treatment becomes more complex and global business demands greater flexibility, containerized RO system supply is reshaping how manufacturers, project owners, and distributors address water quality challenges. This in-depth guide draws on first-hand industry expertise, research, and case analysis to equip B2B buyers and technical managers with actionable knowledge for selecting and deploying containerized RO solutions.

1. Introduction: Why Containerized RO System Supply Is Disrupting the Market

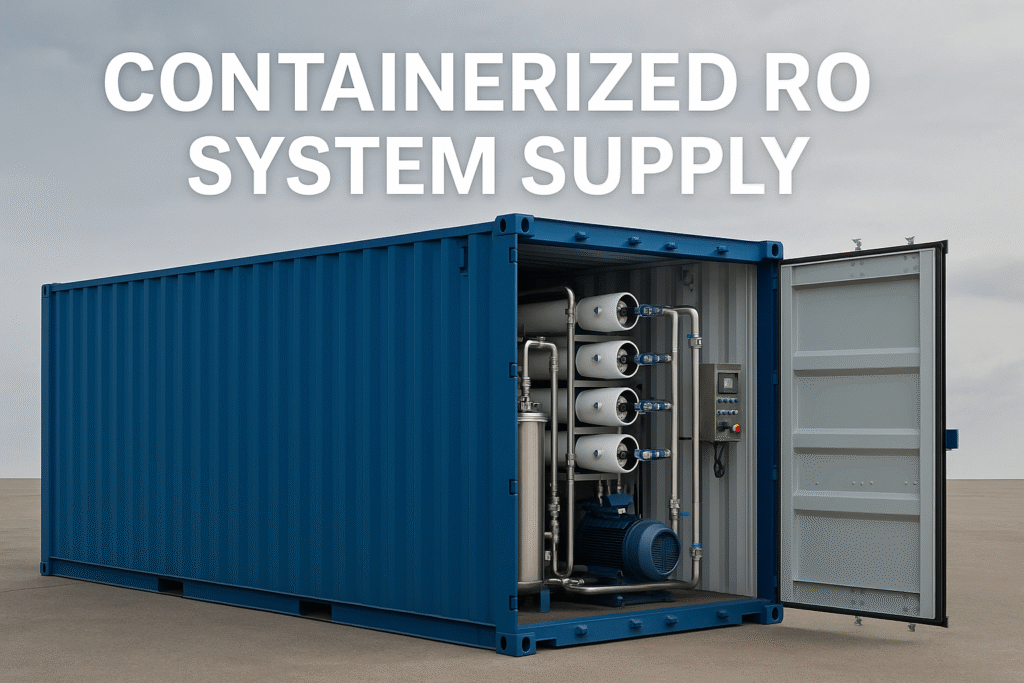

Traditional water treatment plants are expensive, slow to build, and can’t always keep up with the pace of modern business. As project timelines shrink and sites become more remote or temporary, containerized RO systems—pre-engineered, fully assembled, and transportable in shipping containers—deliver a unique blend of agility and reliability. For B2B buyers, this means access to plug-and-play water purification, robust process control, and rapid commissioning—anywhere in the world.

2. What Is a Containerized RO System?

At its core, a containerized RO system is a complete reverse osmosis water treatment plant packaged inside a standard ISO shipping container (typically 20-foot or 40-foot). All major processes—including pretreatment, high-pressure pumping, RO filtration, instrumentation, and control panels—are engineered, assembled, and factory-tested prior to shipment. With minimal on-site work, users can commission the system within days, not months.

- Pre-Assembled: Built in controlled environments for consistent quality.

- Mobile & Flexible: Deployable to remote, temporary, or multi-site projects.

- Turnkey: Only utility hookups needed; no complex construction or specialist labor on site.

- Expandable: Multiple units can be combined for large-scale, phased, or modular projects.

3. Core Advantages for Industrial B2B Clients

The main reason global factories, EPCs, and distributors are embracing containerized RO system supply is the exceptional operational value and risk reduction it brings:

- Speed to Operation: Standardized designs and factory acceptance testing (FAT) ensure rapid, trouble-free installation and startup.

- Space Savings: Compact footprints make them ideal for constrained sites, expansions, or interim water supply during plant upgrades.

- Cost Control: Fewer site hours, reduced need for specialist installation, and lower commissioning costs.

- Reliability: All components are factory-integrated and tested for performance and durability before leaving the facility.

- Regulatory Compliance: Easier to document and certify thanks to standardized builds, proven QA/QC, and global shipment experience.

- Mobility: Units can be relocated, resold, or leased for project-based use, maximizing asset value.

4. Key Design Elements and Customization Options

Every application is unique—so while containerized systems offer standardization, leading suppliers provide a high degree of customization:

- Pretreatment: Sand, multimedia, and activated carbon filtration, plus dosing for antiscalant, chlorine removal, or pH control.

- RO Membranes: Selected for feedwater type (brackish, seawater, industrial wastewater) and required product water quality.

- Automation & Controls: SCADA integration, remote monitoring, and automated alarms for pressure, flow, and conductivity.

- Safety & Compliance: Chemical handling, fire protection, ventilation, and container insulation for challenging environments.

- Auxiliary Systems: CIP (Clean-in-Place), air conditioning, lighting, and anti-corrosion protection.

Choosing the right supplier ensures your containerized RO system will not only fit your feedwater and compliance needs, but also adapt to future process changes or site relocations.

5. Applications Across Industries: Real-World Value

Containerized RO system supply is now routine in sectors where speed, flexibility, and reliability are business-critical:

- Manufacturing: Process water for food & beverage, pharmaceuticals, electronics, and chemicals—often where municipal supply is unreliable.

- Energy: Boiler feed, cooling water, and process makeup for power plants, oil & gas, and refineries.

- Mining & Construction: Mobile water treatment for camps, remote exploration, and temporary infrastructure.

- Emergency Response: Disaster relief and humanitarian missions, supplying safe drinking water in days.

- Municipal & Utility: Capacity expansions, plant maintenance, or drought relief without permanent builds.

According to industry analysis by Global Water Intelligence, demand for modular water treatment solutions is forecast to grow more than 7% CAGR through 2030, with containerized RO as a top performer for B2B projects worldwide.

6. Critical Considerations When Sourcing Containerized RO Systems

- Proven Track Record: Partner with suppliers who have reference projects in your industry and target regions. Experience with international logistics and commissioning is essential.

- Engineering Depth: Look for documentation of process calculations, FAT results, and after-sales support commitments.

- Customization: Don’t settle for one-size-fits-all. Insist on tailored pretreatment, automation, and system layout for your feedwater and site conditions.

- Life Cycle Support: Global technical assistance, spare parts inventory, and operator training protect your investment for years to come.

- Regulatory Alignment: Ensure full compliance with local water quality, electrical, and safety standards—especially for cross-border shipments.

7. Case Example: Fast-Track Project Delivery in Action

A global automotive manufacturer faced a water supply challenge at a new assembly plant in Southeast Asia. With less than 12 weeks before launch, the engineering team opted for a dual-containerized RO system from a proven supplier. Both units were built, factory-tested, and shipped in under 8 weeks. Installation, tie-in, and startup took just four days—delivering ultrapure water well ahead of production targets and eliminating costly delays.

Such results are now standard among manufacturers who view containerized RO as an operational enabler, not just a procurement line item.

8. Frequently Asked Questions (FAQ)

- How quickly can a containerized RO system be installed and started up?

- Most systems can be operational within 1–2 days of delivery, provided site utilities and tie-in points are ready.

- What range of capacities is available?

- Systems can be sized from 5–100 m3/h and up, with multi-container modularization for larger or staged projects.

- Can containerized RO handle seawater or high-salinity feeds?

- Yes—specialized membranes and pretreatment allow operation on seawater, brackish sources, or even some industrial effluents.

- What is the typical lifespan of a containerized RO system?

- With proper maintenance, units routinely deliver 10–20 years of reliable service.

- Are remote monitoring and automation options available?

- Top suppliers offer full SCADA integration, remote diagnostics, and cloud-based data reporting for global fleet management.

9. Conclusion: Elevate Your Water Strategy with Containerized RO System Supply

Containerized RO system supply gives modern B2B customers a powerful toolkit: speed, flexibility, cost efficiency, and proven water quality. Whether expanding a factory, launching a new facility, or responding to urgent water needs, these systems enable businesses to stay agile and compliant in a changing world. By selecting a knowledgeable, experienced partner, you unlock not just a product—but a water treatment solution that delivers value today and adaptability for the future.

Ready to explore containerized RO systems for your next project? Contact an industry-leading supplier for a technical consultation, tailored quotation, and support with global logistics and compliance.