100T ultrafiltration equipment Industrial UF Systems

100T ultrafiltration equipment Industrial UF Systems100T ultrafiltration equipment Industrial UF Systems

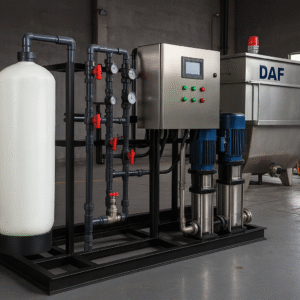

Secure massive volumes of high-quality purified water with Stark Water’s 100T Ultrafiltration Equipment. This large-scale industrial UF system is engineered for superior clarity, efficient pathogen removal, and robust performance, making it ideal for the most demanding industrial and municipal water treatment applications.

Product Beschrijving

For industrial behemoths, sprawling municipalities, and vast agricultural enterprises, the demand for consistently high-quality water runs into immense volumes. Meeting this colossal requirement with efficiency, reliability, and environmental responsibility is a paramount challenge. The Stark Water 100T Ultrafiltration Equipment is precisely engineered to be the definitive solution, providing an advanced and robust system for superior physical separation and purification on an industrial scale.

100T Ultrafiltration Equipment: Engineered for Massive Throughput

The “100T” in its designation signifies an extraordinary capacity of 100 tons per hour (100,000 liters per hour or 100 m³/hr), placing this Ultrafiltration equipment among the largest and most powerful industrial UF systems available. This immense throughput is designed to meet the colossal water demands of major industrial parks, large urban water treatment plants, extensive cooling systems, and large-scale wastewater reuse projects. The core of this system is advanced Ultrafiltration (UF) membrane technology, which utilizes a physical barrier with extremely fine pores (typically 0.01 to 0.1 microns). This ensures highly effective removal of:

- Suspended solids and turbidity

- Colloids and silt

- Bacteria and viruses

- Other microorganisms and particulates

The result is consistently high-quality filtrate, significantly clearer and purer than achievable with conventional filtration, making it suitable for a wide range of applications from primary potable water treatment to advanced industrial process water.

Robust Industrial UF Systems for Diverse Applications

As a leading example of Industrial UF Systems, the STARK 100T Ultrafiltration Equipment is built for unyielding performance in demanding environments. Its robust construction, typically featuring high-grade materials and industrial-strength components, ensures exceptional durability and longevity. This system is highly versatile and can serve various critical roles:

- Primary Water Purification: Providing a standalone solution for drinking water treatment, ensuring safety and clarity for large populations.

- Superior RO Pre-treatment: Acting as an ideal pre-filtration stage for large-scale Reverse Osmosis (RO) systems, protecting sensitive RO membranes from fouling and extending their lifespan significantly.

- Advanced Wastewater Treatment: Producing high-quality effluent in municipal or industrial wastewater treatment plants, making water suitable for discharge, irrigation, or industrial reuse.

- Process Water Clarification: Ensuring pristine water quality for critical industrial processes that require high clarity and low particulate content.

The system is designed for fully automatic operation, incorporating intelligent controls for backwash and Clean-in-Place (CIP) cycles, minimizing manual intervention and maximizing uptime.

Product Parameter

The Stark Water 100T Ultrafiltration Equipment is engineered for massive capacity, robust performance, and high-quality UF purification. Here are its key technical specifications:

| Parameter | Specificatie/aanpassingsopties |

|---|---|

| Kern trefwoord focus | 100T ultrafiltration equipment design and capabilities. |

| Pure Water Capacity | 100 Tons per Hour (100,000 Liters Per Hour / 100 m³/hr / approx. 440 GPM). Custom capacities available. |

| Filtration Technology | Ultrafiltration (UF) Membrane Filtration. |

| Membrane Type | Hollow Fiber UF Membrane (e.g., PVDF, PES), selected based on application and feed water. |

| Pore Size | Typically 0.01 μm – 0.1 μm (e.g., 0.02 μm), selected based on desired filtrate quality. |

| Module Configurations | Large industrial modules, arranged in multiple skids/lines for massive capacities. |

| Operating Mode | Outside-in or Inside-out flow. Can be operated in dead-end or cross-flow filtration modes. |

| Operating Pressure | Typically 0.05 – 0.2 MPa (0.5 – 2 Bar / 7 – 29 PSI). Low pressure operation. |

| Maximum Transmembrane Pressure (TMP) | Generally up to 0.3 MPa (3 Bar / 43 PSI). |

| Raw Water Source Compatibility | Municipal Water, Well Water, Surface Water (rivers, lakes), Pre-treated Wastewater. Customizable for challenging feedwaters. |

| Output Water Quality | Turbidity Reduction: >99%; TSS Reduction: >99%; Bacteria/Virus Removal: >99.9999% (log 6 reduction or higher). SDI < 3. |

| Besturingssysteem | Advanced Fully Automatic PLC Control with HMI, real-time monitoring of flow, pressure, turbidity, auto-backwash, chemical cleaning-in-place (CIP). Remote monitoring and SCADA integration capabilities. |

| Voeding | 3 Phase, 380V/415V/460V, 50Hz/60Hz (Customizable as per regional standards). |

| Construction Material |

|

| Dimensions (Approximate) | Very large industrial footprint; fully customized modular design for large-scale integration (e.g., L 8000mm x W 3000mm x H 3000mm). |

| Bedrijfstemperatuur | 5°C – 45°C (material dependent for broader range). |

| Certification | Designed to meet relevant international standards (e.g., ISO, CE, ASME, upon request). |

Toepasselijke industrie

The STARK 100T Ultrafiltration Equipment is a pivotal solution for achieving massive volumes of high-quality purified water across a broad range of industrial, municipal, and commercial sectors. Its immense capacity and robust design make it indispensable for:

- Municipal Drinking Water Treatment: Provides primary purification or robust pre-treatment for large urban waterworks, effectively removing turbidity, suspended solids, bacteria, and viruses from surface water sources to produce safe potable water.

- Reverse Osmosis (RO) Pre-treatment (Large Scale): Essential for massive RO systems, providing superior pre-filtration that significantly extends the lifespan of expensive RO membranes by effectively removing suspended solids, colloids, and microorganisms from vast influent flows.

- Wastewater Treatment & Reuse (Large Industrial/Municipal): Core component in advanced wastewater treatment facilities (e.g., as part of MBR systems or tertiary treatment), producing immense volumes of high-quality effluent suitable for discharge, irrigation, or industrial reuse, driving water conservation initiatives.

- Major Food & Beverage Production Plants: Used for clarification of process water, juices, wine, beer, and other beverages at very high throughputs; also for pre-filtration prior to sterile processes, ensuring product clarity and safety at industrial scale.

- Pharmaceutical & Biotechnology Giants: Provides purified water for process use and pre-filtration for sterile applications, ensuring high purity and compliance for large-scale manufacturing.

- Power Generation (Large-Scale Utility Water): Supplies immense volumes of clean process water for various operations, including cooling tower make-up water and boiler feed water pre-treatment, preventing fouling and improving efficiency.

- Mining & Metals Industry: For treating vast volumes of process water and wastewater containing high levels of suspended solids and colloids in large-scale mining and metallurgical operations.

- Textile & Dyeing Industry (Large Mills): Used for water recycling and treatment of dye baths to remove suspended particles and color at high volumes, facilitating reuse and reducing discharge.

- Electronics Manufacturing (Pre-UPW): Employed in pre-treatment stages for ultra-pure water (UPW) systems, ensuring removal of particulates from massive water flows to protect downstream purification for sensitive electronics manufacturing.

Voordeel één

Voordeel TWEE

Our 100T Ultrafiltration Equipment is distinguished by its robust industrial design and optimized efficiency, translating into significant long-term value for your water treatment infrastructure. Built with heavy-duty components and durable materials, this industrial UF system is engineered for continuous, demanding operation, ensuring exceptional longevity and minimal downtime even in harsh environments. Its automated control system with self-cleaning capabilities (backwash and CIP) simplifies management and reduces labor costs. Operating at lower pressures compared to RO, it also offers inherent energy efficiency. This combination of rugged construction, high throughput, and efficient operation minimizes maintenance needs, reduces component replacement frequency, and provides a highly reliable and economically sustainable solution for achieving vast volumes of high-quality purified water.

Verwante producten

Gerelateerde producten

-

Apparatuur voor rioolwaterzuivering

STARK Dissolved Air Flotation (DAF) systeem voor voorbehandeling van industrieel afvalwater

Toevoegen aan offerte

FAQ

V1: Hoe lang gaat het omgekeerde osmose systeem mee?

De levensduur van een omgekeerd osmose systeem hangt af van de waterkwaliteit en het onderhoud. Het membraan gaat meestal 2-3 jaar mee, terwijl het systeem zelf meer dan 10 jaar kan meegaan als het goed onderhouden wordt.

V2: Kan het systeem worden aangepast aan verschillende wateromstandigheden?

Ja, al onze systemen zijn volledig aanpasbaar. We analyseren uw waterrapport en toepassingsbehoeften voordat we oplossingen op maat bieden.

V3: Aan welke normen voldoet de apparatuur van STARK?

Onze producten voldoen aan CE, ISO 9001 en kunnen op verzoek worden ontworpen om te voldoen aan specifieke regionale voorschriften of industrienormen.

V4: Wat is de levertijd voor STARK RO-systemen?

Standaardsystemen worden binnen 7-15 dagen verzonden. Voor aangepaste bestellingen kan de levertijd oplopen tot 20-25 dagen, afhankelijk van de complexiteit.

V5: Biedt u technische ondersteuning of begeleiding bij de installatie?

Ja. We bieden volledige technische documentatie, begeleiding op afstand via video en kunnen op verzoek technici internationaal sturen.

V6: Wat is inbegrepen in jullie offerte?

Onze offerte omvat het volledige RO-systeem, het bedieningspaneel, de pompen, de voorbehandelingsunits en alle benodigde appendages. Installatiegereedschap en reserveonderdelen kunnen op verzoek worden meegeleverd.