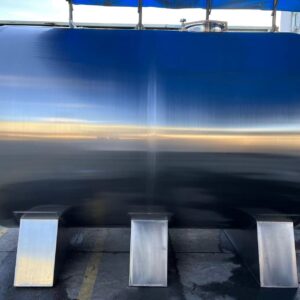

Roestvrij stalen watertank

Conquer extreme corrosive challenges with Stark Water’s Stainless Steel Duplex Steel Water Tank. This advanced stainless steel duplex steel water tank offers unparalleled resistance to pitting and stress corrosion cracking, combined with superior strength, making it the definitive choice for demanding applications like seawater desalination and aggressive industrial environments.

Product Beschrijving

In the most aggressive industrial environments, where traditional stainless steels may eventually succumb to corrosion, a more robust material is required for reliable water storage. The Stainless Steel Duplex Steel Water Tank from Stark Water is meticulously engineered for these challenging conditions, offering a superior solution that combines exceptional strength with unparalleled corrosion resistance. This tank is designed for critical applications where integrity and longevity are non-negotiable, particularly when dealing with high-chloride water or highly corrosive process fluids.

The Unrivaled Strength of Stainless Steel Duplex Steel Water Tank Construction

The defining feature of this product is its construction from duplex stainless steel. Unlike conventional austenitic stainless steels (like 304 or 316L), duplex stainless steels possess a mixed microstructure of approximately equal proportions of austenitic and ferritic phases. This unique metallurgical composition provides a synergistic blend of properties that are far superior to either phase alone:

- Exceptional Corrosion Resistance: Duplex steels offer significantly enhanced resistance to chloride-induced pitting and crevice corrosion, as well as stress corrosion cracking. This makes them indispensable for applications involving seawater, highly brackish water, or aggressive chemical environments where standard stainless steels would degrade.

- Higher Strength: Duplex grades exhibit significantly higher tensile and yield strengths compared to austenitic stainless steels. This allows for thinner tank walls, reducing material weight and potentially manufacturing costs for large tanks, while maintaining or even exceeding structural integrity under pressure.

- Good Weldability: Modern duplex steels offer good weldability, ensuring the integrity of fabricated joints, which is crucial for pressure vessels and large storage tanks.

Choosing a stainless steel duplex steel water tank ensures a remarkably extended operational lifespan and superior performance even in the most hostile environments, providing a highly reliable and long-term asset for your critical water storage needs.

Engineered for Demanding Water Storage Applications

This specialized water tank is designed for demanding applications where ordinary stainless steels might fail. Its robust construction ensures it can safely contain large volumes of water or process fluids, often under significant pressure or varying temperatures. Each tank is fabricated to exacting standards, with meticulous attention to welding procedures and surface finishes to maintain the material’s inherent corrosion resistance. The design can be customized to incorporate specific features such as heating/cooling jackets, agitation systems, specialized inlets/outlets, and instrumentation ports, all while leveraging the superior properties of duplex stainless steel for optimal operational efficiency and hygiene.

Long-Term Reliability and Cost-Effectiveness in Harsh Environments

Investing in a Stainless Steel Duplex Steel Water Tank offers long-term reliability and cost-effectiveness in challenging applications. While the initial material cost might be higher than conventional stainless steels, its unparalleled resistance to corrosion and superior strength translate into a much longer service life, significantly reduced maintenance and replacement costs, and minimized downtime. This makes it a highly economical and sustainable choice for critical infrastructure in industries where environmental conditions or fluid chemistries are extremely aggressive, safeguarding your assets and ensuring uninterrupted operations.

Product Parameter

Stark Water’s Stainless Steel Duplex Steel Water Tank is engineered for superior performance in highly corrosive and demanding environments. Here are its key technical specifications:

| Parameter | Specificatie/aanpassingsopties |

|---|---|

| Kern trefwoord focus | stainless steel duplex steel water tank design and capabilities. |

| Materiaalconstructie | Duplex Stainless Steel (e.g., UNS S31803 / 2205, UNS S32750 / 2507 Super Duplex). Chosen based on specific corrosion resistance and strength requirements (PREN value). |

| Capacity | Customizable to client requirements (e.g., from 500 Liters to 100,000+ Liters). |

| Ontwerptype | Vertical or Horizontal, Cylindrical, with dished, conical, or flat ends. Can be designed as a pressure vessel. |

| Internal Surface Finish | Polished (e.g., Ra < 0.6 μm) or electro-polished for optimal hygiene and flow, and enhanced corrosion resistance. |

| External Surface Finish | Satin polished, Matt finish, #2B finish, or custom painting. |

| Max. Bedrijfsdruk | Customizable, often higher than conventional stainless steel tanks (e.g., up to 2.5 MPa / 25 Bar or more). Designed to client’s pressure requirements. |

| Max. Bedrijfstemperatuur | Customizable, suitable for various hot or cold liquid storage (e.g., -20°C to 200°C). Limited by duplex microstructure at very high temperatures. |

| Corrosiebestendigheid | Excellent resistance to chloride pitting, crevice corrosion, and stress corrosion cracking. Superior to 304/316L. |

| Mechanical Properties | High tensile strength, high yield strength (typically double that of 304/316L). |

| Insulation (Optional) | Polyurethane Foam or Mineral Wool with outer stainless steel cladding for thermal control. |

| Heating/Cooling (Optional) | Jacketed (dimple, coil, or full jacket) or internal coils for precise temperature control. |

| Agitation (Optional) | Top-mounted or side-mounted agitators with sanitary seals. |

| Connections/Fittings | Flanged, threaded, or sanitary connections, customized based on application. Includes manholes, sight glasses, level/temperature/pressure ports. |

| Support Type | Adjustable legs, skirt support, or lug support. |

| Standards Compliance | Designed and manufactured according to relevant industry standards (e.g., ASME, CE, ISO) and specific material standards (ASTM A240, A790 for duplex). |

Toepasselijke industrie

Stark Water’s Stainless Steel Duplex Steel Water Tank is a critical and highly specialized asset for industries that require exceptional corrosion resistance and strength for liquid storage and processing in the most demanding environments. Its superior material properties make it ideal for:

- Seawater Desalination Plants: Essential for storing raw seawater, treated seawater, brine concentrate, and process water loops, where aggressive chloride content would rapidly corrode conventional stainless steels.

- Oil & Gas Industry: For storing produced water, process chemicals, and various fluids in offshore platforms, coastal refineries, and upstream/midstream operations exposed to corrosive brines and H₂S.

- Chemical Processing: Ideal for storing and processing corrosive chemicals, acids, and solutions where high chloride levels or specific aggressive media demand superior material resistance beyond 316L stainless steel.

- Pulp & Paper Industry: Used for storing bleach solutions, digester liquors, and other corrosive chemicals within the paper-making process, where high chloride concentrations are common.

- Wastewater Treatment (Aggressive Streams): For treating and storing highly corrosive industrial wastewater, such as landfill leachate or specific industrial effluents with high chloride or acidic content.

- Marine & Offshore Applications: Storage of various liquids on ships, offshore platforms, and coastal facilities where exposure to saltwater spray and high humidity demands extreme corrosion resistance.

- Mining & Metallurgy: For process water, leaching solutions, and wastewater containing aggressive chemicals or high salt concentrations.

- Power Generation (Coastal Plants): Used for specific water storage needs (e.g., pre-treated cooling water, flue gas desulfurization systems) in coastal power plants exposed to saline environments.

- Pharmaceutical & Biotechnology (Specific Corrosive Processes): For highly specialized processes where sterile conditions are combined with corrosive media, necessitating the highest grade of stainless steel.

Voordeel één

Voordeel TWEE

Verwante producten

Gerelateerde producten

FAQ

V1: Hoe lang gaat het omgekeerde osmose systeem mee?

De levensduur van een omgekeerd osmose systeem hangt af van de waterkwaliteit en het onderhoud. Het membraan gaat meestal 2-3 jaar mee, terwijl het systeem zelf meer dan 10 jaar kan meegaan als het goed onderhouden wordt.

V2: Kan het systeem worden aangepast aan verschillende wateromstandigheden?

Ja, al onze systemen zijn volledig aanpasbaar. We analyseren uw waterrapport en toepassingsbehoeften voordat we oplossingen op maat bieden.

V3: Aan welke normen voldoet de apparatuur van STARK?

Onze producten voldoen aan CE, ISO 9001 en kunnen op verzoek worden ontworpen om te voldoen aan specifieke regionale voorschriften of industrienormen.

V4: Wat is de levertijd voor STARK RO-systemen?

Standaardsystemen worden binnen 7-15 dagen verzonden. Voor aangepaste bestellingen kan de levertijd oplopen tot 20-25 dagen, afhankelijk van de complexiteit.

V5: Biedt u technische ondersteuning of begeleiding bij de installatie?

Ja. We bieden volledige technische documentatie, begeleiding op afstand via video en kunnen op verzoek technici internationaal sturen.

V6: Wat is inbegrepen in jullie offerte?

Onze offerte omvat het volledige RO-systeem, het bedieningspaneel, de pompen, de voorbehandelingsunits en alle benodigde appendages. Installatiegereedschap en reserveonderdelen kunnen op verzoek worden meegeleverd.