TL;DR. If you’re facing BOD TN TP non-compliance, start with a 4–8 week diagnostic, then move through a three-layer playbook: (1) quick control changes (DO/ABAC, internal recycle, SRT, alkalinity, dosing pacing); (2) tertiary polishing and EBPR stabilization to secure phosphorus; (3) structural upgrades (selectors, IFAS/MBBR, MBR, ozone/BAC, UV-AOP). Bring all decisions into a closed loop using online NH4/NO3/PO4/DO/ORP/UV254 data, a compliance dashboard, and defined alarm thresholds.

Back to: Municipal & Public Infrastructure Water Treatment Solutions

What “Non-Compliance” Means in 2025

This section frames how BOD TN TP non-compliance is defined and measured in permits so we fix the real problem, not a data artifact.

- Limits & statistics: permits increasingly use seasonal limits and statistics (e.g., monthly avg, weekly avg, daily max, P95). Always check how excursions are counted.

- Typical targets: BOD/TSS conventional secondary; TN ≤10 mg/L (many regions tighter); TP ≤0.5 mg/L (lower in sensitive waters); NH4 winter caps; turbidity when coupled with reuse/tertiary.

- Verification: recheck sampling points, chain-of-custody, lab QA/QC, and instrument calibration to ensure the problem is process, not data.

A Practical Diagnostic Matrix for BOD TN TP non-compliance

Use this field matrix before buying steel and concrete.

| Objaw | Likely Root Cause | Rapid Check | Quick Fix (≤7 days) | Structural Fix (design level) |

|---|---|---|---|---|

| Effluent NH4 high | Insufficient nitrification (low SRT, cold temps, diffuser/blower limits, low alkalinity) | SRT calc; DO profile; alkalinity; diffuser headloss | Raise SRT (cut WAS), DO 1.5–2.0 mg/L; add alkalinity; enable ABAC | New diffusers/blowers; IFAS media; MBR |

| NO3/TN high | Poor denitrification (no true anoxic, low carbon, internal recycle too low/high) | Anoxic DO <0.2 mg/L? ORP? NO3 load | Lower anoxic DO; set internal recycle 2–4×; pace carbon to NO3 | Selectors, step-feed, intermittent aeration |

| TP swings / rebounds | EBPR instability; nitrate bleed; VFA shortage | Anaerobic PO4 release; VFA; nitrates in selector | Isolate true anaerobic; VFA via primary fermentation; chem-P trim | Tertiary filtration; improved selectors |

| TSS/BOD peaks | Clarifier bottleneck; sludge bulking; hydraulics | SVI; surface overflow; sludge blanket stability | RAS/WAS tuning; floc aid; weir cleaning | Weir/distribution retrofit; tertiary filters; MBR |

| Performance collapses in storms | Short-circuiting; no EQ; bypass | Flow/level curves vs basin HRT | Temporary bypass & EQ; adaptive DO setpoints | EQ basins; hydraulic rebalancing; peak-flow strategy |

| Dosing & air overuse | Open-loop control; sensor drift | Calibration history; variance vs load | Online analyzers; feedback loops (ABAC/NO3-paced carbon/PO4 feedback) | Standardized skids; SCADA upgrades |

| Sudden loss of biology | Toxic or inhibitory industrial discharge | Toxicity screen; ORP anomalies; unusual odors | Bypass/dilution; alkalinity; PAC/GAC dosing | Industrial pretreatment program; online toxicity |

Root Cause #1 — Insufficient Nitrification

The most common driver of BOD TN TP non-compliance in winter is insufficient nitrification.

What it looks like

NH4 spikes in winter; rising effluent NO2; TN above target despite adequate carbon.

Quick fixes

- Raise SRT (cut WAS) to ≥8–12 d in cold conditions.

- Maintain aerobic DO 1.5–2.0 mg/L and verify diffuser performance.

- Restore alkalinity (nitrification consumes ~7.1 mg CaCO3/mg NH4-N).

- Implement ABAC (ammonia-based aeration control) to trim air while protecting effluent NH4.

Design paths

Upgrade diffusers/blowers; introduce IFAS/MBBR media to retain nitrifiers; consider MBR where clarifiers are at capacity or reuse is planned. Explore aeration & MBR modules oraz DO/NH4 analyzers.

Root Cause #2 — Denitrification Failure

Symptoms

Effluent NO3 stuck high; carbon use heavy; ORP hovers too positive in “anoxic” zones.

Quick fixes

- Create true anoxic conditions (DO <0.2 mg/L); fix air leaks.

- Set internal recycle at 2–4× influent; avoid short-circuiting.

- Pace external carbon to NO3-N load using online NO3/ORP; cap max dose and smooth ramps.

Design paths

Add selectors and step-feed; use intermittent aeration; modernize control logic.

Root Cause #3 — EBPR Instability & Phosphorus Rebound

Symptoms

Unstable EBPR is a frequent cause of phosphorus-related BOD TN TP non-compliance, especially at low temperature.

TP swings, particularly at low temperature or variable loads; inconsistent anaerobic PO4 release.

Quick fixes

- Ensure a true anaerobic selector (no nitrate bleed from RAS/IR).

- Increase VFA via primary fermentation or sidestreams.

- Użycie chem-P trimming (alum/ferric) with online orthophosphate feedback.

Design paths

Pair EBPR with tertiary filtration (cloth/disk/sand) to stabilize ≤0.5 mg/L TP; refine selectors and recycles.

Root Cause #4 — Solids Separation & Clarifier Bottlenecks

Symptoms

TSS/BOD peaks, SVI high, sludge blanket unstable, wet-weather washout.

Quick fixes

- Tune RAS/WAS; adjust sludge age; maintain weirs and scum removal.

- Temporary polymer aid during storms or maintenance windows.

Design paths

Retrofit distribution and weirs; add tertiary filters; shift to MBR if clarifiers cap capacity or reuse is priority.

Root Cause #5 — Hydraulics & Wet-Weather Short-Circuiting

Quick fixes

- Deploy temporary equalization; implement adaptive DO setpoints and step-feed during storms.

- Protect solids with conservative surface loading rates and weir uniformity.

Design paths

Construct EQ basins; re-balance hydraulics; define peak-flow bypass strategy with compliant sampling.

Root Cause #6 — Monitoring & Control Gaps

Problem statement

Open-loop dosing and drifting sensors often sit behind recurring BOD TN TP non-compliance.

Open-loop air and chemicals waste cost and cause variability. Sensor drift erodes trust.

Closed-loop solution

- Standardize online NH4/NO3/PO4/DO/ORP/UV254 with calibration SOPs.

- Close loops: ABAC for air; NO3-paced carbon; PO4 feedback for chem-P; UV254 feed-forward for coagulants.

- Connect to PLC/SCADA and historian; institute alarm thresholds and drills.

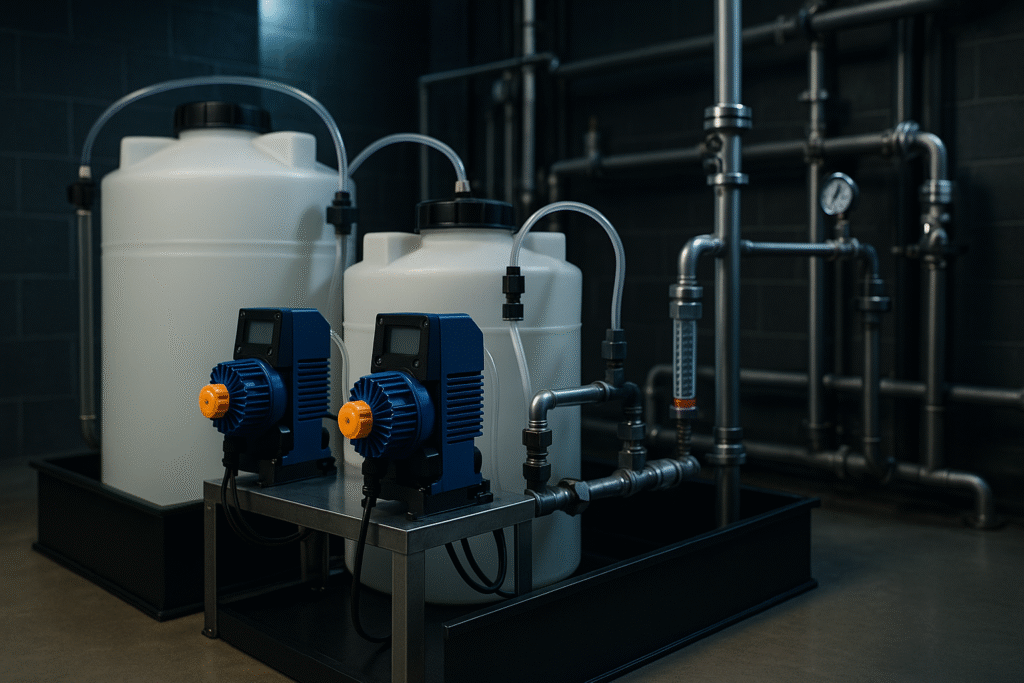

See sensors, analyzers & dosing skids for standardized packages.

Root Cause #7 — Industrial Loads & Toxicity Shocks

Quick fixes

- Bypass/dilution; add alkalinity; PAC/GAC for short-term adsorption.

Longer-term

Implement industrial pretreatment requirements; add online toxicity monitoring; collaborate on source substitution.

Quick Wins You Can Do in 30 Days

- Aeration: replace aged diffusers; verify α/β and SOTE; stage DO; enable ABAC.

- Dosing: convert flow-paced to load-paced with online signals; cap rates, add ramp limits.

- Operations: publish SRT/WAS calendar; clean clarifier weirs; track SVI weekly.

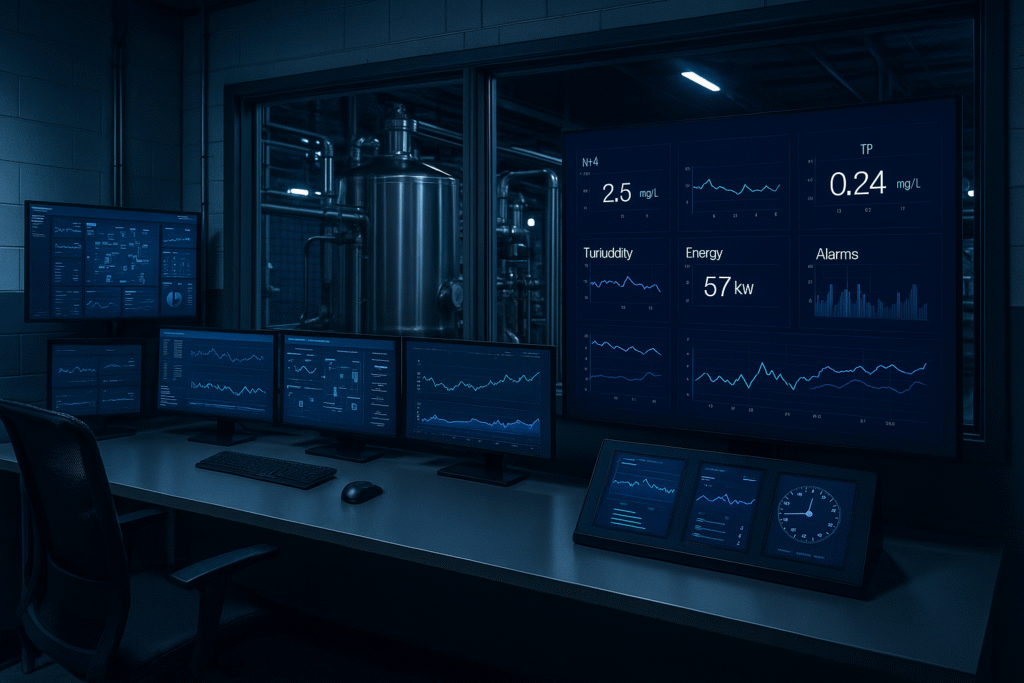

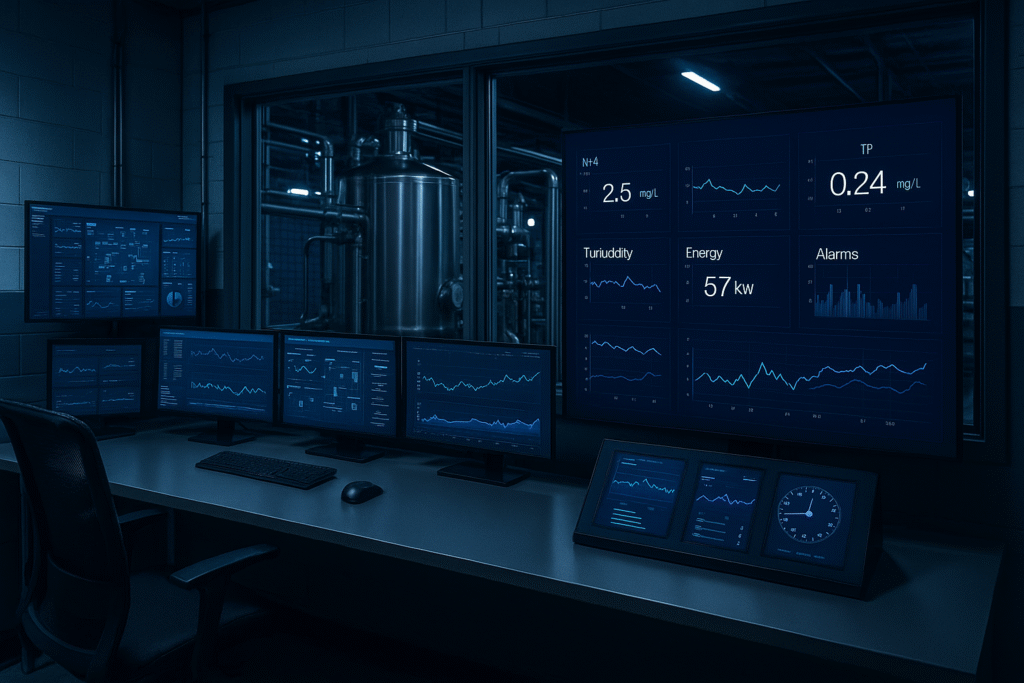

- Data: launch a compliance dashboard with red/amber/green thresholds and daily stand-ups.

These quick wins typically resolve day-to-day BOD TN TP non-compliance while design upgrades are prepared.

Design-Level Fixes

When controls aren’t enough, the following upgrades permanently eliminate BOD TN TP non-compliance.

- Selectors, IFAS/MBBR, or MBR for biology & solids control.

- Tertiary filtration for TSS/TP polishing.

- Ozone + BAC, UV-AOP for micropollutants; add RO/NF if reuse class requires.

- Energy upgrades: high-efficiency blowers, VFDs, optimized control maps.

Browse plant modules oraz akcesoria for specification-ready packages.

Closed-Loop Online Monitoring Architecture

Sensors & setpoints (example)

| Point | Measurement | Use in Control | Konserwacja |

|---|---|---|---|

| Aerobic zones | DO, NH4 | ABAC & DO staging | Calibrate weekly; replace membranes as per OEM |

| Anoxic zones | NO3, ORP | NO3-paced carbon; verify true anoxic | Clean optics; 2-pt check monthly |

| EBPR selector | PO4, NO3 | Prevent nitrate bleed; EBPR health | Weekly check |

| Tertiary influent | PO4, turbidity | Chem-P feedback; filter protection | Weekly check |

| Advanced treatment | UV254/TOC | Ozone/AOP dose control | Clean windows; verify baselines |

Control loops

- ABAC: Target effluent NH4 with DO caps; trim air without risking spikes.

- NO3-paced carbon: External carbon follows NO3-N load with anti-windup and daily caps.

- PO4 feedback: Dose to effluent orthophosphate targets while watching alkalinity and sludge yield.

- UV254 feed-forward: Coagulant dose reacts to organics/turbidity swing before filters.

Data governance & OT security

- Zone OT networks; role-based access; change logs; backup/restore drills.

- Historian with immutable retention for audits; KPI rollups and anomaly detection.

Compliance Dashboard & KPIs

A live dashboard turns BOD TN TP non-compliance into an early-warning signal with actionable thresholds.

| KPI | Why it matters | Typical Target |

|---|---|---|

| NH4, NO3, TN | Nitrogen compliance & air/carbon control | Meet permit; keep guard bands in winter |

| TP | EBPR/chem-P performance | ≤0.5 mg/L; lower with tertiary |

| TSS/Turbidity | Solids capture; filter/AOP readiness | <2–5 NTU typical |

| kWh per m³ | Energy intensity | ≤0.30–0.35 (site-specific) |

| Chemicals per m³ | Cost & carbon footprint | Downward trend with control |

| Alarm response time | Operational discipline | <5 minutes for critical |

Case Snapshots (Anonymized)

Case A — Winter NH4 Spikes

Action: Raise SRT; replace diffusers; enable ABAC. Result: NH4 excursions eliminated; energy −19%.

Case B — EBPR Rebound

Action: True anaerobic selector; VFA via primary fermentation; chem-P trim; tertiary cloth filter. Result: TP 0.25–0.35 mg/L steady.

Case C — Wet-Weather Washout

Action: Temporary EQ; step-feed; clarifier weir retrofit. Result: TSS/BOD peaks disappeared in storms.

Implementation Checklist

Co tydzień

- Instrument calibration (DO/NH4/NO3/PO4/ORP) and grab sample verification.

- SVI, MLSS, SRT calc; WAS calendar adhered.

- Clarifier inspections; weir/scum cleanup.

Miesięcznie

- Energy audit (blower share, kWh per m³); chemical intensity per m³.

- Dashboard review; top 5 alarms; corrective actions logged.

Quarterly/Annual

- HAZOP refresh; emergency drills (ozone/UV safety, chemical handling).

- Process capability & compliance statistics; revamp setpoints.

Najczęściej zadawane pytania

Q1. What are the first three steps to cut TN quickly?

Raise SRT, stabilize DO with ABAC, create true anoxic zones and pace carbon to NO3-N load.

Q2. EBPR unstable—what to check first?

Nitrate bleed into the anaerobic selector, VFA availability, and SRT/temperature alignment for PAOs.

Q3. How to avoid over-dosing external carbon?

Use NO3-paced control with anti-windup and daily caps; audit effluent NO3 and ORP.

Q4. PO4 online readings fluctuate—what’s the fix?

Check sample lines for bubbles; clean optics; perform two-point calibration; confirm with lab.

Q5. How do we keep TSS/BOD compliant during storms?

Equalize flows, step-feed, maintain conservative clarifier loadings, deploy polymer aid, and protect weirs.

Recommended Products & Internal Links

- Accessories & Dosing (sensors, metering pumps, analyzers, ORP/UV254)

- Plant Modules (MBR, aeration systems, tertiary filters)

- Municipal Solutions Pillar

- Zapytanie ofertowe

Autor: STARK Process Engineering Team | Technical review: Senior Municipal Water Specialist | Ostatni przegląd: 2025-08-15

References (add external links on publish): Wytyczne WHO dotyczące jakości wody pitnej; US EPA nutrient removal & advanced wastewater resources; EU Urban Waste Water Treatment Directive; IWA/WEF technical reports on EBPR, aeration, ozone/BAC, and reuse.