Applications of Stainless Steel Prefilters in Water Filtration

Enhance your water filtration system with Stark Water’s Stainless Steel Prefilter. Designed for robust performance, this durable stainless steel prefilter provides essential initial filtration, effectively removing larger particles and sediment to protect downstream equipment and improve overall water quality in various industrial and domestic applications.

Opis produktu

Effective pre-filtration is the cornerstone of any efficient and long-lasting water treatment system. It acts as the crucial first line of defense, safeguarding more sensitive and expensive purification stages from premature wear and fouling. The Stark Water Stainless Steel Prefilter is specifically engineered to excel in this vital role, providing robust, reliable, and high-performance initial filtration for a wide range of water filtration applications.

The Indispensable Role of a Stainless Steel Prefilter in Water Filtration

A stainless steel prefilter is designed to efficiently remove larger suspended solids, sediment, rust particles, and other coarse impurities from raw water. By doing so, it significantly reduces the turbidity and particulate load on subsequent filtration stages, such as cartridge filters, activated carbon filters, UV sterilizers, and especially sensitive membrane systems like Reverse Osmosis (RO) and Ultrafiltration (UF). This pre-filtration step is critical for:

- Extending Equipment Lifespan: Protecting pumps, valves, and finer filters from abrasion, clogging, and damage caused by larger particles.

- Improving System Efficiency: Ensuring optimal performance of downstream components by presenting them with cleaner water.

- Reducing Maintenance Costs: Minimizing the frequency of cleaning or replacement for more expensive filters and membranes.

- Enhancing Overall Water Quality: Contributing to cleaner, clearer water from the outset of the treatment process.

Superior Construction with High-Grade Stainless Steel

The choice of material for a prefilter is paramount, especially given its role in handling raw, often heavily contaminated water. Our prefilters are meticulously constructed from high-grade stal nierdzewna (typically SUS304 or SUS316L). This material offers exceptional durability, corrosion resistance, and structural integrity, allowing the filter to withstand high operating pressures and harsh environmental conditions. Unlike plastic alternatives, stainless steel provides superior resistance to temperature fluctuations, UV degradation, and a broader range of chemical compatibilities, ensuring a long operational lifespan and reliable performance even in demanding industrial settings. The robust construction also contributes to the prefilter’s ability to be easily cleaned and maintained, making it a sustainable and cost-effective long-term solution.

Versatile Design for Diverse Applications

The Stark Water Stainless Steel Prefilter is designed for versatility, compatible with various flow rates and pressure demands. It typically features a mesh or screen-type filtration element (e.g., woven wire mesh or wedge wire screen) capable of filtering down to a specific micron rating (e.g., 50 microns to 200 microns, or finer depending on specific design). The ease of backwashing or manual cleaning of the filter element ensures quick maintenance and minimal downtime. Whether installed as a standalone unit for initial protection or integrated into a multi-stage water treatment plant, its robust design and efficient filtration capabilities make it an indispensable component across a wide array of industrial, commercial, and even large residential water filtration applications.

Parametr produktu

| Parametr | Specyfikacja / opcje dostosowywania |

|---|---|

| Główne słowa kluczowe | Stainless steel prefilter konstrukcja i możliwości. |

| Typ filtra | Prefilter (Mesh Screen or Wedge Wire Element) |

| Materiał Konstrukcja | High-grade Stainless Steel (SUS304 or SUS316L, specified based on corrosion resistance needs). |

| Filtration Rating | Customizable, typically ranging from 50 micron to 200 micron (or finer/coarser as required). |

| Typ projektu | Y-Strainer type, T-type, or straight-through inline design. Backwashable options available. |

| Złącza wlotowe/wylotowe | Threaded (NPT, BSPT) or Flanged (ANSI, DIN, JIS standards), common sizes from ½” to 6″ or larger. |

| Maks. Ciśnienie robocze | Typically 1.0 MPa (10 Bar / 145 PSI) to 1.6 MPa (16 Bar / 232 PSI), customizable for higher pressures. |

| Maks. Temperatura pracy | Up to 95°C (203°F), dependent on sealing materials. |

| Wykończenie powierzchni | Polished or Pickled/Passivated for enhanced corrosion resistance. |

| Materiał uszczelniający | EPDM, Viton (FKM), Buna-N (NBR) (selected based on chemical compatibility and temperature). |

| Przepływ Wydajność | Varies significantly based on size, connection, and micron rating (e.g., from 1 m³/hr to 500+ m³/hr). |

| Metoda czyszczenia | Manual flush/backwash, brush cleaning, or automated self-cleaning systems available. |

| Instalacja | Vertical or horizontal installation, depending on model. |

Obowiązująca branża

- Industrial Water Treatment: Essential for pre-filtration in factories, power plants, and large-scale water treatment facilities, protecting expensive RO membranes, UF systems, EDI units, ion exchange beds, and pumps from suspended solids, grit, and large particulate matter.

- Municipal Water Systems: Used in raw water intake lines or before primary treatment stages to remove larger debris, protecting pumps and preventing clogging of filtration media.

- Przemysł spożywczy: Filters process water for beverage production, food washing, and pre-filtration for ingredient water, ensuring initial clarity and hygiene.

- Chemical Processing: Protects pumps and sensitive equipment from particles in process water, cooling water, and various chemical solutions.

- HVAC i wieże chłodnicze: Removes suspended solids from circulating cooling water, preventing fouling, improving heat exchange efficiency, and extending the lifespan of cooling systems.

- Agricultural & Irrigation Systems: Essential for filtering irrigation water (e.g., from rivers, wells) to prevent clogging of sprinklers, drip lines, and other irrigation components.

- Pharmaceuticals (Utility Water): Used for pre-filtering utility water lines to protect downstream purification systems and general facility equipment.

- Przemysł tekstylny i farbiarski: Filters process water used in dyeing and washing, preventing impurities from affecting fabric quality and color.

- Mining & Metals Industry: For primary filtration of process water, washdown water, and wastewater containing heavy suspended solids.

- Residential (Large Scale/Well Water): Ideal for large homes or properties with private well water systems to remove sand, silt, and rust before the water enters the main plumbing system.

Advantage One

Przewaga DWÓCH

Powiązane produkty

Podobne produkty

- Domowy oczyszczacz wody

STARK 5000L Household Water Purifier Ultrafiltration Membrane Pvdf Memebrane

Dowiedz się więcej - Domowy oczyszczacz wody

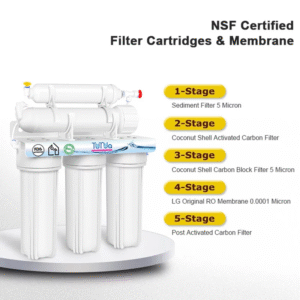

75GPD Reverse Osmosis Household Water Purifier | 5-Stage Water Filter Purifier

Dowiedz się więcej

FAQ

P1: Jak długo działa system odwróconej osmozy?

Żywotność systemu odwróconej osmozy zależy od jakości wody i konserwacji. Zazwyczaj membrana wytrzymuje 2-3 lata, podczas gdy sam system może wytrzymać ponad 10 lat przy odpowiedniej pielęgnacji.

P2: Czy system można dostosować do różnych warunków wodnych?

Tak, wszystkie nasze systemy są w pełni konfigurowalne. Analizujemy raporty wodne i potrzeby aplikacji przed dostarczeniem dostosowanych rozwiązań.

P3: Jakie standardy spełnia sprzęt STARK?

Nasze produkty są zgodne z normami CE, ISO 9001, a na życzenie mogą być zaprojektowane tak, aby spełniały określone przepisy regionalne lub normy branżowe.

P4: Jaki jest czas dostawy systemów STARK RO?

Standardowe systemy są wysyłane w ciągu 7-15 dni. W przypadku niestandardowych zamówień czas realizacji może wydłużyć się do 20-25 dni w zależności od złożoności.

P5: Czy zapewniasz wsparcie techniczne lub wskazówki dotyczące instalacji?

Tak. Zapewniamy pełną dokumentację techniczną, zdalne wskazówki za pośrednictwem wideo, a na życzenie możemy wysłać inżynierów za granicę.

P6: Co jest zawarte w wycenie?

Nasza oferta obejmuje kompletny system RO, panel sterowania, pompy, jednostki oczyszczania wstępnego i wszystkie niezbędne elementy. Narzędzia instalacyjne i części zamienne mogą być dołączone na życzenie.