Why this guide? If you search for RO membrane unit conversion during design or maintenance, you need fast tables you can trust, practical conductivity tips (normalized to 25 °C), and clear installation/removal steps that prevent seal mistakes and early performance loss.

ASTM water conductivity methods

NIST conductivity temperature compensation

Reviewed by Stark Water Process Engineering Team • Last updated: 2025-11-03 • Reading time: 9–12 min

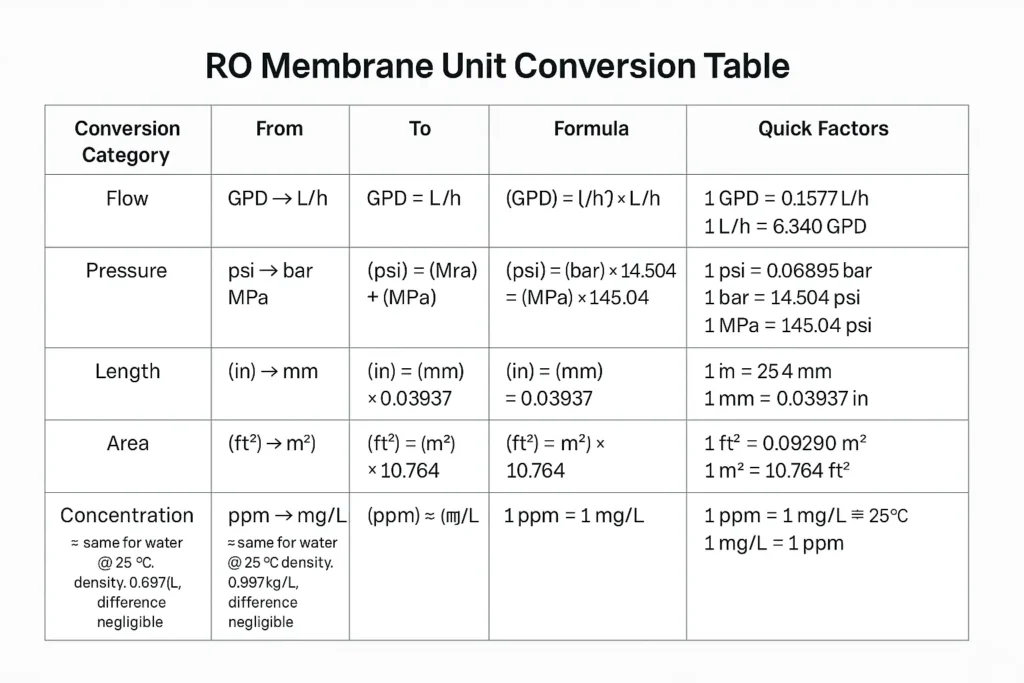

RO membrane unit conversion tables (engineer’s cheat-sheet)

Common element sizes

| Code | Nominal OD | Length | Typical area (ft² / m²) |

|---|---|---|---|

| 2540 | 2.5 in ≈ 63.5 mm | 40 in ≈ 1,016 mm | 28–40 ft² (2.6–3.7 m²) |

| 4040 | 4.0 in ≈ 101.6 mm | 40 in ≈ 1,016 mm | 70–90 ft² (6.5–8.4 m²) |

| 8040 | 8.0 in ≈ 203.2 mm | 40 in ≈ 1,016 mm | 365–440 ft² (33.9–40.9 m²) |

Use this RO membrane unit conversion table to switch GPD↔L/h fast.

Length & area

| Length | Conversion | Area | Conversion |

|---|---|---|---|

| in → mm | × 25.4 | in² → cm² | × 6.4516 |

| mm → in | ÷ 25.4 | ft² → m² | × 0.092903 |

| ft → m | × 0.3048 | m² → ft² | × 10.7639 |

Durchfluss

| From | To | Factor | Example |

|---|---|---|---|

| GPD | L/day | × 3.785 | 10,000 GPD → 37,850 L/d |

| GPD | L/h | × 0.1577 | 10,000 GPD → 1,577 L/h |

| m³/h | GPM (US) | × 4.402 | 2.5 m³/h → 11.0 GPM |

For pumps/instruments, this RO membrane unit conversion sheet avoids mix-ups.

Druck

| From | To | Factor | Typical RO usage |

|---|---|---|---|

| psi | bar | × 0.0689476 | 600 psi ≈ 41.4 bar (brackish) |

| bar | MPa | × 0.1 | 41.4 bar ≈ 4.14 MPa |

| kPa | psi | × 0.145038 | 690 kPa ≈ 100 psi |

Concentration & chlorine shorthand

| Artikel | Rule | Example |

|---|---|---|

| ppm vs mg/L | In dilute water, 1 ppm ≈ 1 mg/L | Free Cl ≤ 0.05 mg/L at RO feed |

| TDS (mg/L) | ≈ Conductivity (µS/cm) × 0.5–0.8 (water-specific) | 500 µS/cm → ~300–400 mg/L |

Temperature: K, °C and °F conversion

| Relationship | Formula | Example |

|---|---|---|

| °F → °C | (°F − 32) × 5/9 | 77 °F → 25 °C |

| °C → °F | (°C × 9/5) + 32 | 25 °C → 77 °F |

| °C → K | °C + 273.15 | 25 °C → 298.15 K |

Conductivity: calibration & 25 °C compensation

Always compare conductivity at the same temperature. The industry norm is 25 °C. A simple engineering estimate for compensation is a linear 2 %/°C:

Faustformel (10–40 °C): σ25 ≈ σT ÷ [1 + 0.02 × (T − 25)]

- Reference solutions: Calibrate with known KCl standards (e.g., 0.01 M and 0.02 M) and verify against a table at the bath temperature.

- Cell constant: If unknown, back-calculate using a standard. Re-verify monthly in industrial service.

- Process tip: Normalize permeate conductivity to 25 °C before trending salt passage.

How to install RO membranes (feed-to-concentrate, brine seal facing feed)

This procedure minimizes seal damage and start-up issues. Read OEM manuals first and comply with site LOTO.

- Isolate, depressurize and lock/tag out. Remove vessel endplate at the concentrate end.

- Rinse vessel; lightly glycerin-wipe interior if allowed.

- Insert the first element from the feed end with the brine-seal lip facing the feed side.

- Join elements with approved couplers; lubricate O-rings as allowed; keep couplers fully seated.

- Install thrust ring at concentrate end; fit adapter and O-rings; re-install endplate/clip per OEM torque.

- Push the stack toward concentrate to remove slack; shim to prevent axial movement; reconnect piping.

- Leak check with low pressure water; verify ΔP is normal before full-pressure operation.

How to remove RO membranes (safe extraction & labeling)

- Isolate, depressurize, drain and LOTO. Remove external lines and the concentrate endplate.

- Push from the feed end to extract elements one by one—catch and bag each element.

- Tag element order and orientation; protect seals; record serials and vessel IDs for traceability.

- Inspect O-rings, couplers, brine seals and endcaps; replace damaged parts before reassembly.

Acceptance checks after installation/removal

- Mechanisch: correct element count and order, brine-seal orientation, endplate clips/torque, no axial play.

- Hydraulic: baseline ΔP, permeate flow and salt passage vs. datasheet (normalized to 25 °C).

- Records: vessel/element tags, photos, torque data, and sign-off.

FAQ — quick answers that rank

How do I convert GPD to L/h for an 8040 train?

Multiply by 0.1577. Example: 10,000 GPD ≈ 1,577 L/h.

What’s 600 psi in bar and MPa?

600 psi ≈ 41.4 bar ≈ 4.14 MPa.

Which way does the brine seal face?

Toward the feed end. The lip faces incoming feed to prevent bypass.

Why convert conductivity to 25 °C?

Conductivity rises about 2 % per °C. Normalizing to 25 °C ensures trends reflect salt passage, not temperature swings.

What if my conductivity cell constant is unknown?

Calibrate with KCl standards (e.g., 0.01 M/0.02 M), calculate the constant, and re-verify monthly.

Nächste Schritte (RFQ & interne Links)

Share your RO design case—our team will review sizing, verify interstage hydraulics and propose the right stainless-steel housings.

Editorial standards (EEAT): Content prepared by Stark Water process engineers and quality-checked by senior staff with 10+ years in industrial RO. Procedures must be validated against your OEM manuals and site safety rules.