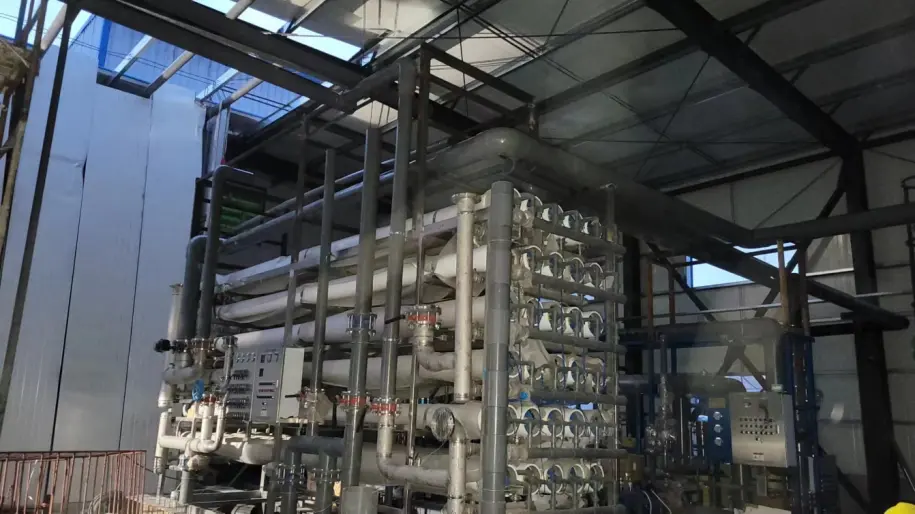

Scenario: Reuse of mine/process water inside a factory area. System capacity combines a 5000 T/D pretreatment line feeding a 4000 T/D single-stage RO, with automated operation and stable permeate quality for utilities and production.

| Country / Site | Singapore / industrial mining-water reuse inside plant |

|---|---|

| Total Capacity | Pretreatment 5000 T/D (≈208 m³/h) → RO 4000 T/D (≈167 m³/h) |

| Influent Risks | Suspended solids, fines, turbidity swings; dissolved metals; occasional hydrocarbons; scaling species (Ca, Ba, Sr, silica). |

| Process Train | Equalization → coagulation/flocculation → lamella clarifier (or DAF per influent) → multimedia filtration → activated carbon (organics & de-chlorination) → optional UF (SDI control) → 5 µm cartridge → RO (8040 brackish) → permeate tank & distribution. |

| Materials | HP RO piping SS316; pretreatment vessels carbon-steel lined / FRP; skids SS304; chemical-resistant elastomers. |

| Contrôles | PLC + HMI; trend logging for turbidity/SDI/ΔP/cond; interlocks to EQ tanks; auto permeate flush & standby modes. |

Design Basis & Targets

- Recovery: RO set around 70–75% (balancing silica/metals scaling indices and flux).

- Permeate quality: typically ≤ 30–50 µS/cm for utilities; polishing options available if ultra-low conductivity is required.

- SDI control: ≤ 3 at RO inlet; UF module enabled when seasonal fines increase.

- Metal risk management: pH conditioning and coagulant selection validated via jar tests.

- CIP readiness: dedicated CIP tank/pumps, validated acid/alkali recipes per membrane OEM limits.

Process Highlights

- Equalization & clarification buffer shock loads; lamella plates or DAF chosen by oil/fines ratio.

- Dual-media filters + ACF stabilize turbidity and remove oxidants/organics ahead of RO.

- RO arrays with VFD HP pumps, interstage sampling, and programmable flush to protect membranes.

- Chemical program: antiscalant; optional sodium metabisulfite or carbon for de-chlorination; non-oxidizing biocide as needed.

- Brine handling: segregated blowdown to plant utilities for further treatment/disposal per local regulation.

Commissioning & Handover

- FAT → SAT → performance run with water balance and quality mapping (influent/RO feed/permeate/brine).

- Training: SDI testing, log-sheet KPIs (flow, pressure, ΔP, conductivity), CIP trigger thresholds.

- Deliverables: P&ID, layout, I/O list, SOPs, PM plan, membrane cleaning record templates.