This engineering guide explains how to plan an industrial di water system—from RO pretreatment and EDI vs mixed bed choices to sizing tables, resistivity targets, polishing steps, instrumentation, and a bill-of-materials template. It is written for factories, laboratories, food & beverage plants, hotels, and surface-treatment shops that need reliable deionized water from wells or municipal supplies.

1) What Is a DI Water System (vs RO & “Ultrapure”)?

A di water system deionizes water by removing dissolved ions to reach a target resistivity or conductivity. RO (reverse osmosis) is usually the primary desalting step; electrodeionization (EDI) or a mixed bed (SAC+SBA resins) then polishes the RO permeate to very low ionic levels. “Ultrapure” is a use-case label (electronics/analytical labs), not a single machine. Final requirements depend on your industry standard and validation plan.

In practice: wells/municipal feed → pretreatment (particulates, organics, hardness control) → RO → EDI or mixed bed → UV (microbial/TOC control) → 0.2 μm final filter → storage and recirculating loop (if required).

2) Quality Targets & Conversions (Resistivity ↔ Conductivity)

Specify quality as resistivity (MΩ·cm) ou conductivity (μS/cm). The quick conversion is:

conductivity (μS/cm) = 1 / resistivity (MΩ·cm)

Examples: 18.2 MΩ·cm ≈ 0.055 μS/cm; 1.0 MΩ·cm ≈ 1.0 μS/cm; 0.2 MΩ·cm ≈ 5 μS/cm.

| Application (typical) | Common target | Notes |

|---|---|---|

| General industrial rinse, boilers makeup (non-high-pressure) | 0.1–1.0 MΩ·cm (10–1 μS/cm) | RO + mixed bed often sufficient |

| Laboratory Type II/III, many F&B utilities | ≥ 1–10 MΩ·cm (≤ 1–0.1 μS/cm) | RO + EDI or high-capacity mixed bed |

| Electronics/analytical Type I | ~18 MΩ·cm (~0.055 μS/cm) | EDI + polishing loop; add TOC control |

Les valeurs ci-dessus sont engineering starting points. Use your sector’s standard (e.g., lab water types, corporate SOPs) for formal acceptance criteria.

3) Di Water System Process Trains that Work in Industry

Storage & loop — stainless steel tank with vent filter, spray ball and recirculation to maintain quality.

Prétraitement — multimedia filtration (MMF) and activated carbon; add softening or antiscalant to protect RO; keep SDI low.

RO desalting — core TDS removal; choose element count/staging for temperature, recovery, and fouling risk.

EDI or Mixed Bed polishing — see Section 4 for selection and sizing.

UV (254 nm) et 0.2 μm final filter — control microbes and particulates before points of use.

4) Fast Sizing: RO, EDI or Mixed Bed

4.1 RO Sizing (early estimate)

- Design permeate flow Qp (m³/h) and target recovery R (%) → feed ≈ Qp/R.

- Initial flux for brackish RO: start around 10–15 LMH (L/m²·h) and adjust per membrane datasheet and temperature.

- Pick vessel/element count after vendor selection; small plants often use 2:1 ou 2:2 staging; larger trains may use 3:2, etc.

- Keep recovery conservative if fouling/scaling risk is high; validate with antiscalant software or pilot data.

4.2 EDI vs Mixed Bed — Selection

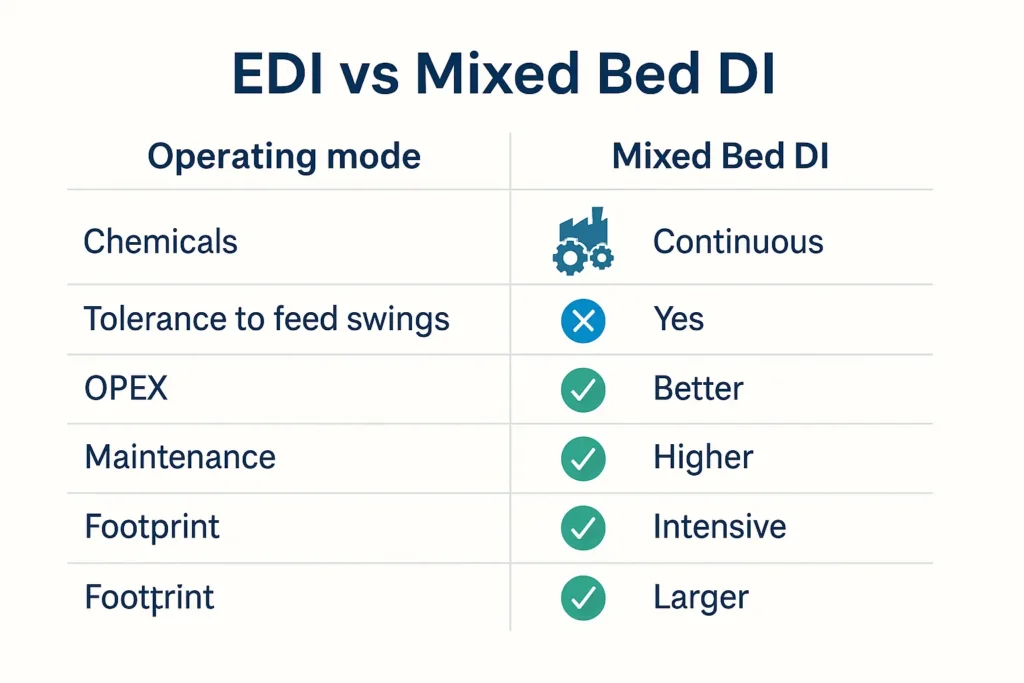

| Criteria | EDI polishing | Mixed bed polishing |

|---|---|---|

| Operating mode | Continuous, no bulk chemicals | Batch; requires acid/caustic regeneration |

| Feed water window | Works best with stable RO permeate (low hardness/CO2) | More tolerant to feed swings |

| Uptime / staffing | High uptime; skilled commissioning | Simple hardware; periodic regen |

| OPEX | Electric power; periodic clean-in-place | Acid/caustic, neutralization & safety |

| Targets | High resistivity with stable operation | Can reach high resistivity; performance depends on resin & regimen |

4.3 EDI Sizing (rule-of-thumb)

- Confirm RO permeate is within the vendor window (low hardness, low silica/CO2, low TOC).

- Select stack size by product flow (m³/h) et ionic load; apply temperature factor and safety margin for seasonal swings.

- Allow bypass/recirculation for load spikes; instrument with resistivity and flow on each skid outlet.

4.4 Mixed Bed Sizing (rule-of-thumb)

Mixed bed capacity is expressed as equivalents per liter (eq/L). Estimate required resin volume:

Resin volume (L) ≈ [meq/L (ionic load after RO) × flow (m³/h) × run time (h)] ÷ [resin capacity (eq/L)] × safety factor

Set (jeu de mots) run time to your preferred regeneration interval (e.g., 8–24 h). Use supplier capacity for your resin grade and chemistry.

5) Polishing, Storage & Distribution

- UV at 254 nm for microbial control; add 185 nm UV if TOC reduction is required by SOP.

- Final filter 0.2 μm at point-of-use or before loop return; sterile vents on storage tanks.

- Storage tank in SS304/316L with spray ball, sloped bottom, and recirculation nozzle.

- Loop in SS or sanitary plastic; size for turbulent velocity to maintain quality.

6) Materials & Instrumentation

- Pipework: UPVC/PP for pretreatment; SS316L or sanitary plastics downstream of polishing.

- Key meters: conductivity/resistivity (at RO permeate, polisher outlet, loop return), TOC (if required), SDI, flow, ΔP.

- Safety: chemical dosing bunds, eyewash, neutralization capacity for mixed-bed regeneration waste.

Related products:

- RO membranes & housings, dosing pumps, activated carbon

- Stainless-steel contact/storage tanks

- Water-treatment calculators

7) Bill-of-Materials (BOM) Template

- Pretreatment: MMF, GAC, softener or antiscalant dosing, cartridge filters

- RO skid: high-pressure pump, vessels/elements, interstage instrumentation, CIP ports

- Polisher: EDI stacks ou mixed bed resin vessels with regeneration/CIP accessories

- Polishing: 254 nm UV (option 185 nm), 0.2 μm final filter, sanitary valves & gauges

- Storage & loop: SS316L tank with vent filter & spray ball, recirculation pump, loop instruments

- Controls: PLC/HMI, resistivity/TOC transmitters, flow/ΔP, quality interlocks and alarms

- Docs: P&ID, layout, FAT/SAT checklists, IQ/OQ templates

Get an Engineering Proposal

Share your feed analysis and target quality (resistivity or conductivity), product flow, and utilities. We will return a BOM & P&ID recommendation.

8) FAQ

Is a di water system the same as reverse osmosis?

No. RO removes most dissolved salts; a di water system adds a polishing step (EDI or mixed bed) to reach very low ionic levels.

EDI vs mixed bed—when should I choose each?

Choose EDI for continuous operation without bulk chemicals and stable RO permeate; choose a mixed bed for wider tolerance to feed swings or when simple batch regeneration fits the site better.

What resistivity should I target?

Use the requirement in your SOP or industry guideline. As a starting point: 1–10 MΩ·cm for many industrial uses; ~18 MΩ·cm for Type I lab water.

Can I retrofit DI after an existing RO?

Yes. Verify RO permeate quality and flow/pressure; then add EDI or a mixed bed skid, plus UV and a 0.2 μm filter before storage/loop.

9) References (External)

Stark Water Engineering Team