This engineering guide shows commercial and industrial users how to design an iron filter for well water—from diagnosis to process trains, sizing rules and commissioning—so you can remove iron (Fe) and manganese (Mn) reliably and protect fixtures, heat exchangers and downstream processes. It also links to stainless-steel contact tanks et valves/media & accessories for immediate specification.

1) Diagnose the Water

Test Fe, Mn, H2S (odor), pH, temperature and note any iron bacteria (slimy deposits). Record design/peak flow (m³/h or gpm) and the available backwash flow from the pump and drain.

Document seasonal changes; fluctuating wells benefit from the chlorination + contact tank route.

With H2S or iron bacteria, plan for chemical oxidation + contact time before filtration.

pH ≥ ~6.8 typically improves oxidation and media performance.

2) Iron Filter for Well Water — When Each Process Fits

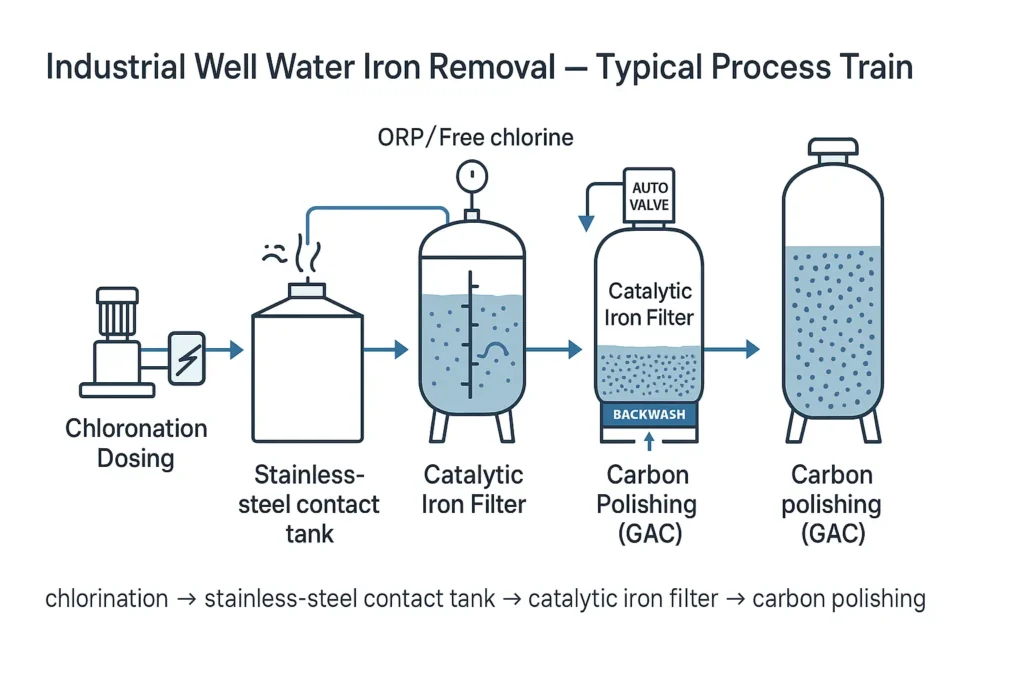

An iron filter for well water is not a single cartridge; it is a process. Choose air injection + catalytic media for low–moderate iron without odor, and choose chlorination + contact tank + catalytic filtration when iron is high, manganese is present, or when odor/iron bacteria must be controlled with disinfection.

Plants with limited backwash capacity can parallel smaller vessels or use chemical oxidation to shift the load from the filter to the contact tank.

3) Proven Process Trains (Commercial/Industrial)

- Air Injection (AIO) → Catalytic Media — low-maintenance for low–moderate iron without odor.

- Chlorination → Contact Tank → Catalytic Filter → GAC — robust for higher Fe/Mn, H2S, or iron bacteria.

- Greensand+/High-MnO₂ with regeneration — stable when Fe & Mn are both elevated; design higher backwash.

4) Iron Filter For Well Water Quick Selection Matrix

| Water Condition | Recommended Train | Key Notes |

|---|---|---|

| Fe ≤ 3–5 mg/L, no odor | AIO (air injection) + catalytic media | Simple O&M; verify backwash capability |

| Fe > 3–5 mg/L or H2S / iron bacteria | Chlorination → contact tank → catalytic filter → GAC polishing | Most robust for fluctuating wells; allows disinfection |

| Fe and Mn both elevated | Greensand+ / high-MnO₂ media (with regeneration) | Design higher backwash; monitor ΔP and bed expansion |

5) Fast Sizing: Area, Diameter & Backwash

For catalytic media, a practical starting point is a service rate ≈ 10 gpm/ft² et backwash 12–15 gpm/ft². Convert flow with 1 m³/h = 4.403 gpm. Final design depends on media spec sheet, temperature and water chemistry.

| Design Flow | Filter Area (ft²) | Suggested Tank Diameter | Backwash (12–15 gpm/ft²) |

|---|---|---|---|

| 5 m³/h (≈22 gpm) | ≈2.2 | ≈20″ (e.g., 21×62) | ≈26–33 gpm |

| 10 m³/h (≈44 gpm) | ≈4.4 | ≈28–30″ | ≈53–66 gpm |

| 20 m³/h (≈88 gpm) | ≈8.8 | ≈40–42″ | ≈106–132 gpm |

Tip: If your pump cannot supply enough backwash, parallel smaller vessels or add a dedicated backwash pump. Pair chemical oxidation + contact time to reduce the load per vessel.

Sizing an Iron Filter for Well Water with Limited Backwash

Where drain/pump limits exist, split a single large vessel into two smaller units with staggered backwash. This keeps the iron filter for well water operating within media expansion ranges while staying inside site utilities.

6) Contact Time (CT) & Dosing

For chlorination, target a free-chlorine residual of ~0.2–0.5 mg/L at the contact-tank outlet (adjust to local code and downstream processes). Provide ~5–10 minutes of effective contact time in a baffled stainless-steel contact tank.

Metering-pump sizing (general):

L/h of NaOCl ≈ (Required mg/L as Cl2 × Flow m³/h × 1000) ÷ (Available chlorine of solution, mg/L)

Example: dose 2 mg/L at 10 m³/h using ~10% NaOCl (≈100,000 mg/L) → 0.2 L/h (plus safety factor for demand swings).

7) Commissioning Checklist

- Verify NaOCl strength; set metering pump stroke and calibration column reading.

- Confirm residual at contact-tank outlet; odor eliminated downstream.

- Backwash each filter until effluent clears; record baseline ΔP.

- Log ORP/free-chlorine, ΔP and flow weekly for the first month.

Get an Engineering Recommendation

Send your Fe/Mn/H2S, pH, peak flow et backwash capacity. We’ll return a BOM & P&ID recommendation.

8) FAQ

Do I need a contact tank or is air injection enough?

A contact tank is preferred when iron is high, H2S/odor or iron bacteria are present, or when you need disinfection stability.

Which media should I choose?

Katalox Light/high-MnO₂ works well across a wide pH window; Greensand+ is mature and effective with regeneration. Match media to Fe/Mn levels and available backwash.

What about activated carbon?

Use GAC to remove residual chlorine and improve taste/odor, especially after chlorination.

What documents do you provide?

Sizing sheets, media loading charts, start-up/commissioning checklist and maintenance schedule.

Stark Water Engineering Team — Experience in groundwater iron/manganese removal for hotels, schools, food & beverage and light industry.

9) References (External)

- EPA – Secondary Drinking Water Standards (Iron & Manganese)

- CDC – Private Wells: Testing & Treatment Basics

Stark Water Engineering Team — Experience in groundwater iron/manganese removal for hotels, schools, food & beverage and light industry.