Peralatan ultrafiltrasi 15T Sistem UF Industri

Peralatan ultrafiltrasi 15T Sistem UF IndustriPeralatan ultrafiltrasi 15T Sistem UF Industri

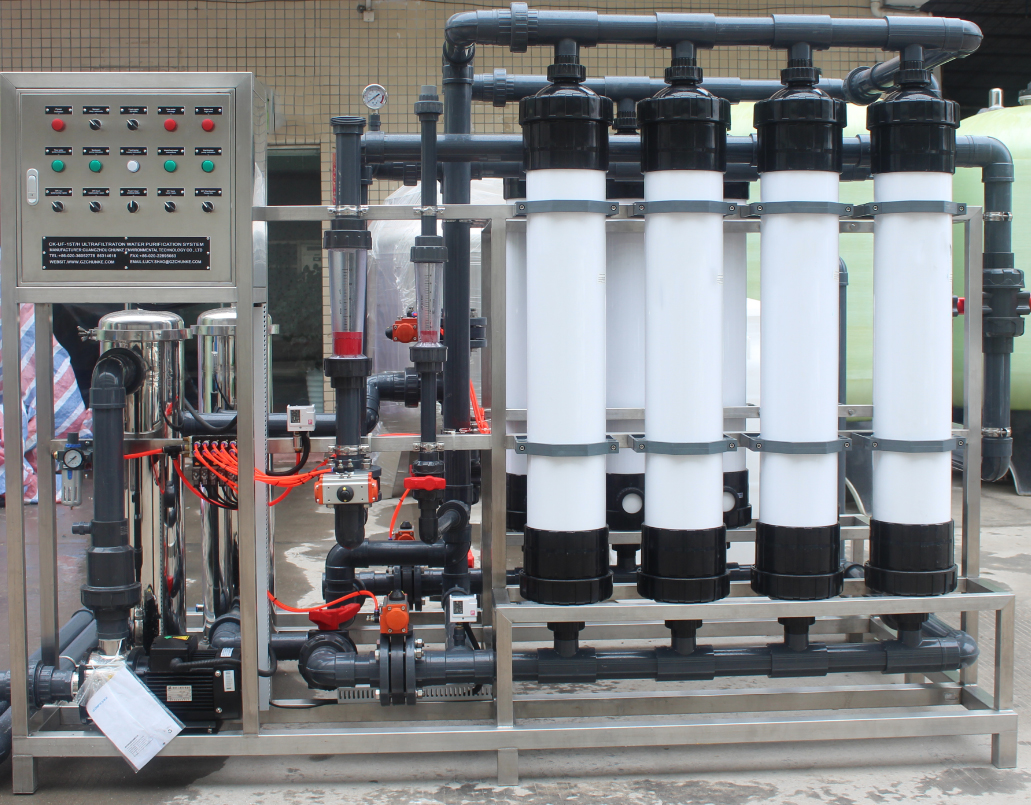

Secure reliable and high-quality purified water with Stark Water’s 15T Ultrafiltration Equipment. This advanced 15T ultrafiltration equipment is an industrial UF system, meticulously designed for efficient removal of suspended solids, bacteria, and viruses, providing superior clarity for mid-scale industrial and commercial water treatment applications.

Deskripsi Produk

For industrial and commercial operations that require a substantial yet manageable volume of high-quality purified water, finding the right balance of capacity, efficiency, and cost-effectiveness is crucial. The Stark Water 15T Ultrafiltration Equipment is precisely engineered to strike this balance, offering a robust and highly efficient solution for superior physical separation and purification on a mid-to-large industrial scale. This advanced system is a testament to our commitment to providing tailored and reliable water treatment solutions.

15T Ultrafiltration Equipment: Optimized for Mid-Scale Industrial Demands

The “15T” in its designation signifies a significant capacity of 15 tons per hour (15,000 liters per hour or 15 m³/hr), making this 15T ultrafiltration equipment ideally suited for mid-sized industrial facilities, commercial complexes, and municipal water treatment plants. This capacity ensures a consistent and abundant supply of purified water, capable of meeting the substantial demands of various production lines, process requirements, or community water supplies without over-sizing. At its core, this equipment utilizes advanced Ultrafiltration (UF) membrane technology, which functions as a physical barrier with extremely fine pores (typically 0.01 to 0.1 microns). This highly effective process ensures superior removal of:

- Suspended solids and turbidity

- Colloids and silt

- Bakteri dan virus

- Other microorganisms and particulates

The result is consistently high-quality filtrate, significantly clearer and purer than achievable with conventional filtration, perfectly preparing water for further treatment or direct use.

Robust Industrial UF Systems for Versatile Applications

As a leading example of Industrial UF Systems, the STARK 15T Ultrafiltration Equipment is built for unyielding performance and long-term reliability in demanding environments. Its robust construction, typically featuring high-grade materials and industrial-strength components, ensures exceptional durability and longevity. This system is highly versatile and can serve various critical roles:

- Primary Water Purification: Providing a standalone solution for drinking water treatment, ensuring safety and clarity for medium-sized populations or facilities.

- High-Efficiency RO Pre-treatment: Acting as an ideal pre-filtration stage for Reverse Osmosis (RO) systems, protecting sensitive RO membranes from fouling by suspended solids, colloids, and microorganisms, thereby extending membrane lifespan and reducing cleaning frequency.

- Pengolahan & Penggunaan Kembali Air Limbah: Producing high-quality effluent in municipal or industrial wastewater treatment plants (e.g., as part of MBR systems or tertiary treatment), making water suitable for discharge, irrigation, or industrial reuse applications at a manageable scale.

- Process Water Clarification: Ensuring pristine water quality for critical industrial processes that require high clarity and low particulate content.

The system is designed for fully automatic operation, incorporating intelligent controls for backwash and Clean-in-Place (CIP) cycles, minimizing manual intervention and maximizing uptime.

Parameter Produk

The Stark Water 15T Ultrafiltration Equipment is engineered for mid-to-large capacity, robust performance, and high-quality UF purification. Here are its key technical specifications:

| Parameter | Opsi Spesifikasi / Kustomisasi |

|---|---|

| Fokus Kata Kunci Inti | 15T ultrafiltration equipment design and capabilities. |

| Kapasitas Air Murni | 15 Tons per Hour (15,000 Liters Per Hour / 15 m³/hr / approx. 66 GPM). Custom capacities available. |

| Teknologi Filtrasi | Filtrasi Membran Ultrafiltrasi (UF). |

| Jenis Membran | Hollow Fiber UF Membrane (e.g., PVDF, PES), selected based on application and feed water. |

| Ukuran Pori-pori | Typically 0.01 μm – 0.1 μm (e.g., 0.02 μm, 0.03 μm), selected based on desired filtrate quality. |

| Module Configurations | Industrial modules, typically skid-mounted units for easier installation. |

| Mode Operasi | Aliran luar-dalam atau dalam-ke luar. Dapat dioperasikan dalam mode filtrasi buntu atau aliran silang. |

| Tekanan Operasi | Biasanya 0,05 - 0,2 MPa (0,5 - 2 Bar / 7 - 29 PSI). Operasi tekanan rendah. |

| Tekanan Transmembran Maksimum (TMP) | Generally up to 0.3 MPa (3 Bar / 43 PSI). |

| Kompatibilitas Sumber Air Baku | Air Kota, Air Sumur, Air Permukaan (sungai, danau), Air Limbah yang telah diolah sebelumnya. Dapat disesuaikan untuk air umpan yang menantang. |

| Kualitas Air Keluaran | Pengurangan Kekeruhan: >99%; Pengurangan TSS: >99%; Penghapusan Bakteri / Virus: >99,9999% (pengurangan log 6 atau lebih tinggi). SDI <3. |

| Sistem Kontrol | Fully Automatic PLC Control with HMI, real-time monitoring of flow, pressure, turbidity, auto-backwash, chemical cleaning-in-place (CIP). Remote monitoring capabilities. |

| Catu Daya | 3 Fase, 380V/415V/460V, 50Hz/60Hz (Dapat disesuaikan sesuai standar regional). |

| Bahan Konstruksi |

|

| Dimensi (Perkiraan) | Mid-to-large industrial footprint; typically skid-mounted design (e.g., L 3000mm x W 1500mm x H 2000mm). |

| Suhu Operasi | 5°C - 45°C (tergantung bahan untuk rentang yang lebih luas). |

| Sertifikasi | Dirancang untuk memenuhi standar internasional yang relevan (misalnya, ISO, CE, ASME, berdasarkan permintaan). |

Industri yang Berlaku

The STARK 15T Ultrafiltration Equipment is a pivotal solution for achieving significant volumes of high-quality purified water across a broad range of industrial, municipal, and commercial sectors. Its optimal capacity and robust design make it indispensable for:

- Municipal Drinking Water Treatment (Mid-Scale): Provides primary purification or robust pre-treatment for mid-sized urban waterworks or rural communities, effectively removing turbidity, suspended solids, bacteria, and viruses from surface water sources to produce safe potable water.

- Reverse Osmosis (RO) Pre-treatment (Mid-Scale): Essential for RO systems, providing superior pre-filtration that significantly extends the lifespan of expensive RO membranes by effectively removing suspended solids, colloids, and microorganisms from influent flows.

- Wastewater Treatment & Reuse (Industrial/Municipal): Core component in advanced wastewater treatment facilities (e.g., as part of MBR systems or tertiary treatment), producing high-quality effluent suitable for discharge, irrigation, or industrial reuse at a substantial scale.

- Food & Beverage Industry (Mid-Scale Plants): Used for clarification of process water, juices, wine, beer, and other beverages at significant throughputs; also for pre-filtration prior to sterile processes, ensuring product clarity and safety.

- Pharmaceutical & Biotechnology (Process Water): Provides purified water for various process uses and pre-filtration for sterile applications in medium-sized manufacturing facilities, ensuring high purity and compliance.

- Industrial Process Water (General): Supplies clean process water for various manufacturing operations, preventing fouling of equipment and improving product consistency.

- Menara Pendingin & Air Umpan Boiler: Menghilangkan padatan tersuspensi dan beban mikroba dari air make-up, mencegah penskalaan, biofouling, dan meningkatkan efisiensi sistem utilitas besar.

- Textile & Dyeing Industry: Used for water recycling and treatment of dye baths to remove suspended particles and color at significant volumes, facilitating reuse and reducing discharge.

- Manufaktur Elektronik (Pra-UPW): Digunakan dalam tahap pra-pengolahan untuk sistem air ultra-murni (UPW), memastikan penghilangan partikulat untuk melindungi pemurnian hilir untuk manufaktur elektronik yang sensitif.

Keuntungan Satu

Keuntungan DUA

Produk Terkait

Produk Terkait

-

Pabrik pengolahan air

160 m³/jam Pemurni Air UF | Ultrafiltrasi Serat Berongga | STARK

Tambahkan ke Kutipan

PERTANYAAN YANG SERING DIAJUKAN

T1: Berapa lama sistem reverse osmosis bertahan?

Umur dari sistem reverse osmosis tergantung pada kualitas air dan pemeliharaan. Biasanya, membran bertahan selama 2-3 tahun, sedangkan sistem itu sendiri dapat bertahan lebih dari 10 tahun dengan perawatan yang tepat.

T2: Dapatkah sistem disesuaikan berdasarkan kondisi air yang berbeda?

Ya, semua sistem kami dapat disesuaikan sepenuhnya. Kami menganalisis laporan air dan kebutuhan aplikasi Anda sebelum memberikan solusi yang disesuaikan.

T3: Standar apa yang dipatuhi oleh peralatan STARK?

Produk kami memenuhi CE, ISO 9001, dan dapat dirancang untuk memenuhi peraturan regional atau standar industri tertentu berdasarkan permintaan.

T4: Berapa waktu pengiriman untuk sistem STARK RO?

Sistem standar dikirim dalam waktu 7-15 hari. Untuk pesanan yang disesuaikan, waktu tunggu dapat diperpanjang hingga 20-25 hari tergantung pada kerumitannya.

T5: Apakah Anda menyediakan dukungan teknis atau panduan pemasangan?

Ya. Kami menyediakan dokumentasi teknis lengkap, panduan jarak jauh melalui video, dan dapat mengirimkan teknisi secara internasional berdasarkan permintaan.

T6: Apa saja yang termasuk dalam penawaran Anda?

Kutipan kami mencakup sistem RO lengkap, panel kontrol, pompa, unit pra-perawatan, dan semua perlengkapan yang diperlukan. Alat instalasi dan suku cadang dapat disertakan berdasarkan permintaan.