bwro vs membrana swro is a common design question. This guide compares feed salinity, operating pressure, salt rejection, staging, pretreatment, and typical use cases so you can choose the right element for industrial RO.

Przeglądaj membrany RO Otwarty kalkulator rozmiaru RO

Szybka odpowiedź

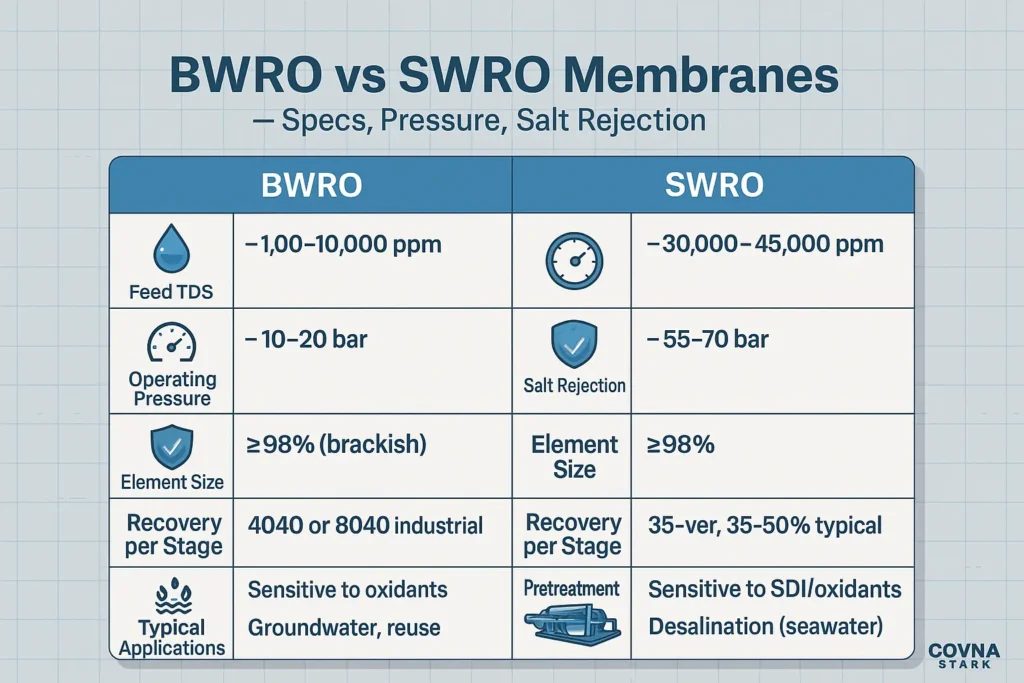

BWRO (brackish water) treats salinity typically from 1,000 to 10,000 mg/L TDS at moderate pressure. SWRO (seawater) treats about 30,000 to 45,000 mg/L TDS at high pressure. Both use thin-film composite membranes, but SWRO elements are designed for higher differential and osmotic pressures with tighter structures and specialized high-pressure pumps and vessels.

bwro vs swro membrane — design considerations

Wyrażenie bwro vs membrana swro mainly reflects differences in osmotic pressure, pressure rating, and recovery strategy. Brackish systems operate where osmotic pressure is moderate, so multi-stage designs can push higher recovery per stage without sacrificing cross-flow. Seawater systems face very high osmotic pressure and therefore run lower per-stage recovery with higher feed pressure and careful anti-scalant control. When choosing between the two, compare normalized performance at the same temperature, verify vessel ratings, and size pumps for the actual pressure window rather than nameplate values. In practice, the bwro vs membrana swro choice is driven by feed envelope (TDS, SDI, oxidants), energy cost, footprint, and service access in the plant layout.

Energy and ERD for SWRO

Because seawater osmotic pressure is high, SWRO power consumption dominates lifecycle cost. Modern trains pair high-efficiency pumps with energy-recovery devices (isobaric ERDs or turbines) to recapture pressure from the concentrate stream. Evaluate specific energy in kWh per m³ at normalized conditions and include pressure losses through pretreatment and piping. For BWRO, ERDs are rarely economical, but pump efficiency and staging still matter. Use this framework to compare a bwro vs membrana swro design on total cost of ownership rather than element price alone.

bwro vs swro membrane — side-by-side

| Parametr | BWRO | SWRO |

|---|---|---|

| Typical feed TDS | ~1,000–10,000 mg/L | ~30,000–45,000 mg/L |

| Typical operating pressure | ~8–25 bar (model dependent) | ~50–70+ bar (model dependent) |

| Odrzucenie soli | Usually 98%± (brackish) | Usually 99%± (seawater) |

| Common element size | 4040 or 8040 for industrial BWRO | 8040 for industrial SWRO |

| Recovery per stage | Higher per stage; total 45–75% typical | Lower per stage; total 35–50% typical |

| Pretreatment sensitivity | Sensitive to SDI/iron, moderate pressure limits | Very sensitive; strict dechlorination and SDI control |

| Typical applications | Groundwater, well fields, reuse polishing | Desalination plants, offshore, resorts, islands |

Operating Pressure & Pumps

Because seawater has a much higher osmotic pressure, swro trains require high-pressure pumps and vessels rated accordingly. Brackish trains typically use multistage centrifugal pumps. When comparing bwro vs membrana swro power requirements, evaluate permeate production at normalized conditions, pump efficiency, and energy-recovery devices for SWRO.

Pretreatment & Scaling Control

- Maintain SDI within supplier limits (commonly ≤3) and use adequate cartridge filtration (5 µm typical).

- Dechlorinate completely before TFC membranes; verify no oxidant breakthrough.

- Use antiscalant and pH control appropriate to saturation indices; watch for silica and barium/strontium scales.

- Plan for periodic CIP and proper preservation during downtime to prevent biofouling.

For detailed cleaning procedures, see RO membrane cleaning.

Staging, Recovery, and Flux

BWRO can achieve higher per-stage recovery and often uses 2:1 or 3:2 staging in 8″ trains. SWRO commonly runs lower recovery per stage to keep cross-flow and limit scaling. Keep per-stage differential pressure within supplier limits and compare performance using normalized (temperature-corrected) data. For element format differences, see Membrana 4040 vs 8040 ro.

How to Select for Your Project

- Confirm feed envelope — TDS, temperature, SDI, oxidants, silica, iron/manganese.

- Pick element family — BWRO or SWRO model tested for your envelope and pressure limits.

- Size staging and pumps — balance recovery with cross-flow, pressure, and energy.

- Engineer pretreatment — filtration, dechlorination, antiscalant, and monitoring.

Select BWRO/SWRO Membranes See Replacement Checklist

Case examples

A resort island with 35–40 g/L TDS selects SWRO with 8040 elements at 55–65 bar feed pressure, two-pass polishing for low boron, and ERDs to keep specific energy near 3–4 kWh/m³. A wellfield project at 3–6 g/L TDS selects BWRO with 8040 elements, 3:2 staging, and higher total recovery to reduce concentrate hauling. Both projects share the same pretreatment logic—cartridge filtration, strict dechlorination, and antiscalant—but the operating window and hardware ratings differ because of the bwro vs membrana swro choice.

References

Instrukcja techniczna DuPont FilmTec RO/NF | Arkusz informacyjny AMTA - Czyszczenie na miejscu (CIP)

Najczęściej zadawane pytania

Is SWRO always 8040?Does SWRO have better rejection than BWRO?Can I run BWRO elements on seawater?

Request a Model Match

Send feed TDS/temperature, SDI, target permeate flow, and design recovery. We will recommend a matched BWRO or SWRO element, vessel rating, and staging.

Get BWRO/SWRO Quotes Use RO Sizing Calculator

For element format and vessel interfaces after this bwro vs membrana swro comparison, see Membrana 4040 vs 8040 ro.