Clean, safe, and consistent water quality is non-negotiable for industries ranging from food processing to electronics and pharmaceuticals. At the core of reliable water treatment, especially in reverse osmosis (RO) systems, is the **CTO carbon filter**—an advanced solution designed to remove chlorine, taste, and odor while safeguarding sensitive downstream membranes and equipment. This expert guide delivers in-depth analysis, actionable selection advice, and real-world applications for CTO carbon filters, helping you make informed sourcing and operational decisions.

What Is a CTO Carbon Filter? (Definition and Working Principle)

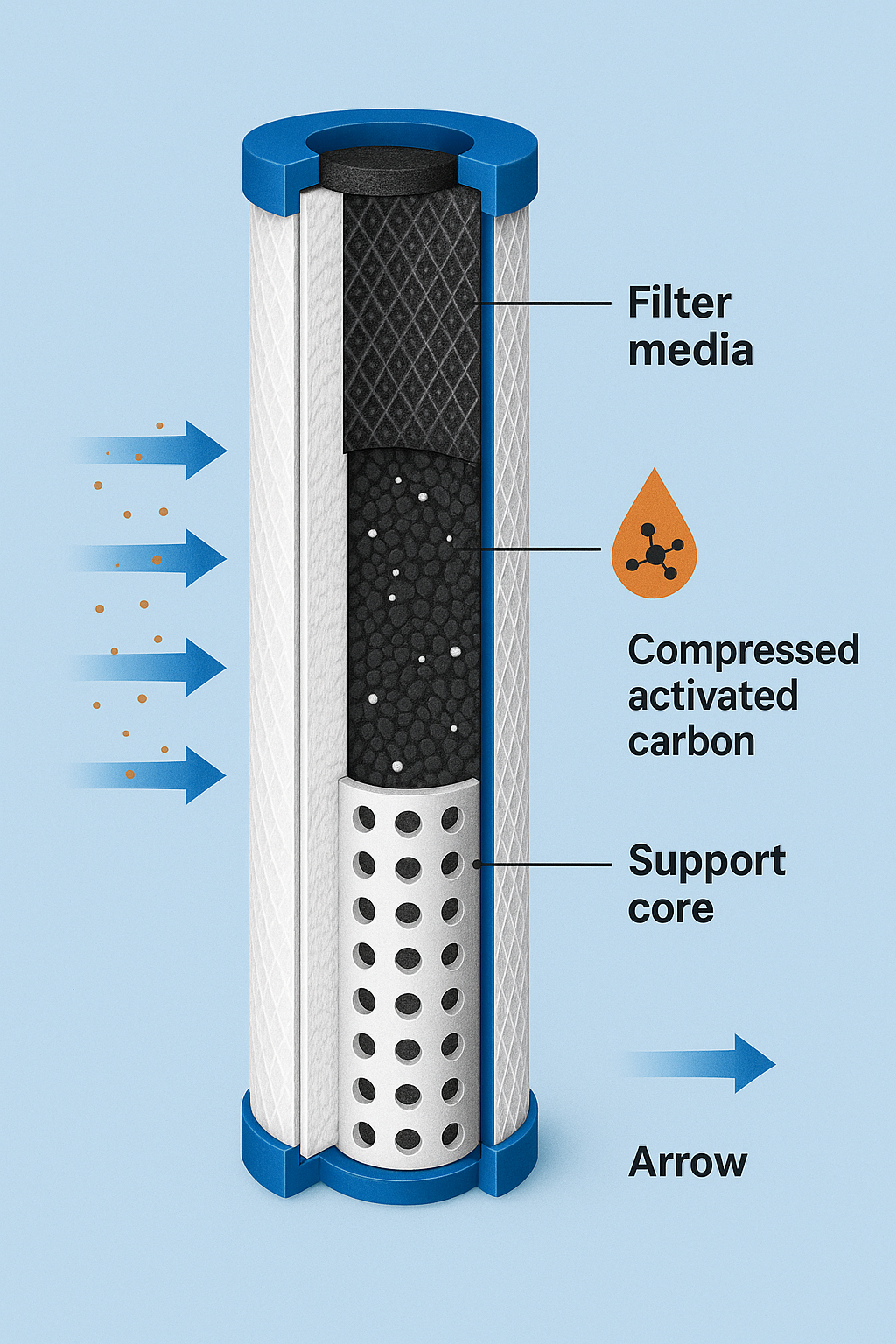

A CTO carbon filter is a specialized cartridge filter composed of compressed (block) activated carbon, engineered to address three critical water quality parameters: **Chlorine**, **Taste**, and **Odor** (hence the acronym CTO). Installed as a pre-filtration stage in RO systems or point-of-use devices, the CTO carbon filter works by adsorbing chlorine and organic compounds—protecting delicate RO membranes from irreversible damage while enhancing water palatability for end uses.

- Material: Made from high-purity coconut shell or coal-based activated carbon, processed into a rigid block for maximum surface area.

- Micron Rating: Typically 5 micron or lower, providing both chemical adsorption and fine particle filtration.

- Structure: Core and outer wrap designed for high flow rates, low pressure drop, and long service life.

Why CTO Carbon Filters Are Essential in Industrial Water Treatment

Chlorine removal is more than an aesthetic issue—it is vital for protecting RO membranes, which are highly susceptible to oxidative attack. A single breakthrough of chlorine can reduce membrane lifespan by up to 90%, resulting in costly replacements and production downtime. CTO carbon filters offer:

- Superior Chlorine Reduction: Achieving >99% removal efficiency at specified flow rates.

- Enhanced Taste and Odor Control: Removal of volatile organic compounds (VOCs) and byproducts.

- Particle Filtration: Simultaneous removal of sediment, rust, and micro-debris, supporting overall system reliability.

- Regulatory Compliance: Critical for food, beverage, and pharmaceutical production lines that demand consistent, safe water quality.

Key Technical Parameters and Sizing Guidelines

CTO carbon filters are available in various sizes, flow rates, and configurations. For industrial and high-volume commercial applications, parameters to consider include:

- Dimensions: Most common are 20″ x 4.5″ (Big Blue), compatible with high-capacity filter housings.

- Micron Rating: 5 micron is standard for balance of flow and protection; finer grades available for specialty uses.

- Flow Rate: Must be matched to system demand; typical industrial CTO filters support up to 4–6 GPM per cartridge.

- Chlorine Capacity: Measured in mg/L or ppm; select a cartridge with sufficient adsorption capacity for source water conditions and replacement intervals.

- NSF/ANSI Certification: Ensure compliance with recognized global safety and performance standards.

For an example of a high-quality industrial CTO carbon filter, visit our CTO Carbon Filter product page.

CTO vs. GAC Carbon Filters: What’s the Difference?

Not all carbon filters are created equal. CTO (carbon block) and GAC (granular activated carbon) are the two dominant forms:

- CTO Carbon Block: Denser structure, higher surface area, lower channeling risk, superior particle removal, and longer service life. Preferred for RO pre-filtration and industrial process applications.

- GAC: Looser, granular bed; greater risk of channeling and incomplete contact. Faster flow but lower particulate retention. Sometimes used for taste/odor at point-of-use.

For industrial and commercial clients, CTO is generally the filter of choice for its performance and reliability in demanding environments.

Industrial Applications: Where CTO Carbon Filters Make a Difference

- Reverse Osmosis Systems: Primary pre-filtration for all RO plants—prevents chlorine damage and improves product water quality.

- Beverage & Food Processing: Ensures compliance and preserves flavor profiles in brewing, bottling, and food manufacturing.

- Pharmaceutical & Laboratory: Protects downstream ultra-pure water equipment, supporting stringent quality protocols.

- Cooling Towers & Boilers: Reduces organic fouling and scaling potential in recirculating water loops.

- Municipal and Decentralized Water: Key component in community, school, and hospital water safety programs.

CTO carbon filters are also widely used as part of multi-stage water purification systems, ensuring consistent operation under variable water quality conditions.

How to Select the Right CTO Carbon Filter for Your Facility

- Analyze Source Water: Determine chlorine levels, organic load, and sediment profile using lab testing or supplier analysis.

- Specify Application: Is it for RO pre-treatment, process water, food-grade, or utility water? Each may require different ratings or certifications.

- Calculate System Flow & Replacement Interval: Estimate peak demand and desired changeout schedule for cost-effective operation.

- Assess Certification Needs: Choose filters with NSF, ANSI, or other industry-relevant approvals, especially for regulated applications.

- Partner with Reliable Suppliers: Engage vendors who offer technical support, batch traceability, and robust product documentation. Explore Stark Water’s CTO Carbon Filter options here.

Best Practices for Installation, Maintenance, and Performance

- Correct Housing: Always match cartridge size and flow direction with compatible filter housings to avoid bypass and leaks.

- Flush on Startup: After installation, flush the CTO filter according to manufacturer recommendations to remove loose carbon and fines.

- Monitor Pressure Drop: Install gauges before and after the filter to track clogging and optimize replacement timing.

- Follow a Regular Replacement Schedule: Do not exceed rated chlorine capacity or maximum recommended service life—both water quality and system safety may be compromised.

- Recordkeeping: Document all cartridge changes for quality audits, traceability, and performance improvement.

Frequently Asked Questions (FAQ)

- How long does a CTO carbon filter last in industrial service?

- Typical replacement is every 3–6 months, but actual life depends on source water quality, chlorine load, and flow rates.

- Can CTO filters remove heavy metals or microorganisms?

- No—while they excel at chlorine and organic removal, they do not remove dissolved metals or pathogens. Use additional filtration (RO, UV) as required.

- Are CTO filters suitable for high-temperature or high-pressure systems?

- Most are rated up to 45°C and 100 psi. Check manufacturer specifications for special applications.

- What’s the difference between 5 micron and 1 micron CTO filters?

- Lower micron ratings capture finer particles but may reduce flow rate and require more frequent changeout. Balance with system needs.

- Do CTO filters impact taste?

- Yes—removal of chlorine and organics greatly improves water flavor and odor, important for F&B and potable applications.

Industry Trends and Expert Insights

The global demand for CTO carbon filters is rising, driven by stricter water quality regulations and the growth of decentralized water treatment. Emerging innovations include enhanced catalytic carbon, multi-function cartridges, and IoT-enabled filter monitoring for predictive maintenance. According to Water Technology Online, high-purity carbon blocks will remain essential in B2B and critical process applications for the foreseeable future.

Based on our team’s project experience, investing in high-grade CTO filters and robust monitoring translates directly into longer membrane life, fewer process interruptions, and better product water quality for clients across industries.

Conclusion: CTO Carbon Filters as the Backbone of Reliable Water Treatment

For any factory, distributor, or engineer responsible for process water or RO system integrity, the CTO carbon filter is an indispensable line of defense. Choosing the right cartridge, monitoring its performance, and following best practices will ensure sustained water quality, regulatory compliance, and long-term cost control. For tailored advice or to source industry-leading CTO carbon filters, connect with our technical experts today.