This practical guide compares edi vs mixed bed polishing in an industrial di water system. You’ll get a decision matrix, field-tested sizing rules, typical OPEX differences, feed-water windows, polishing steps, and a concise BOM you can send to procurement. Focus: commercial/industrial users — electronics, laboratories, food & beverage, hotels, plating, and light pharma (note: DI is not WFI).

1) Basics: What They Do

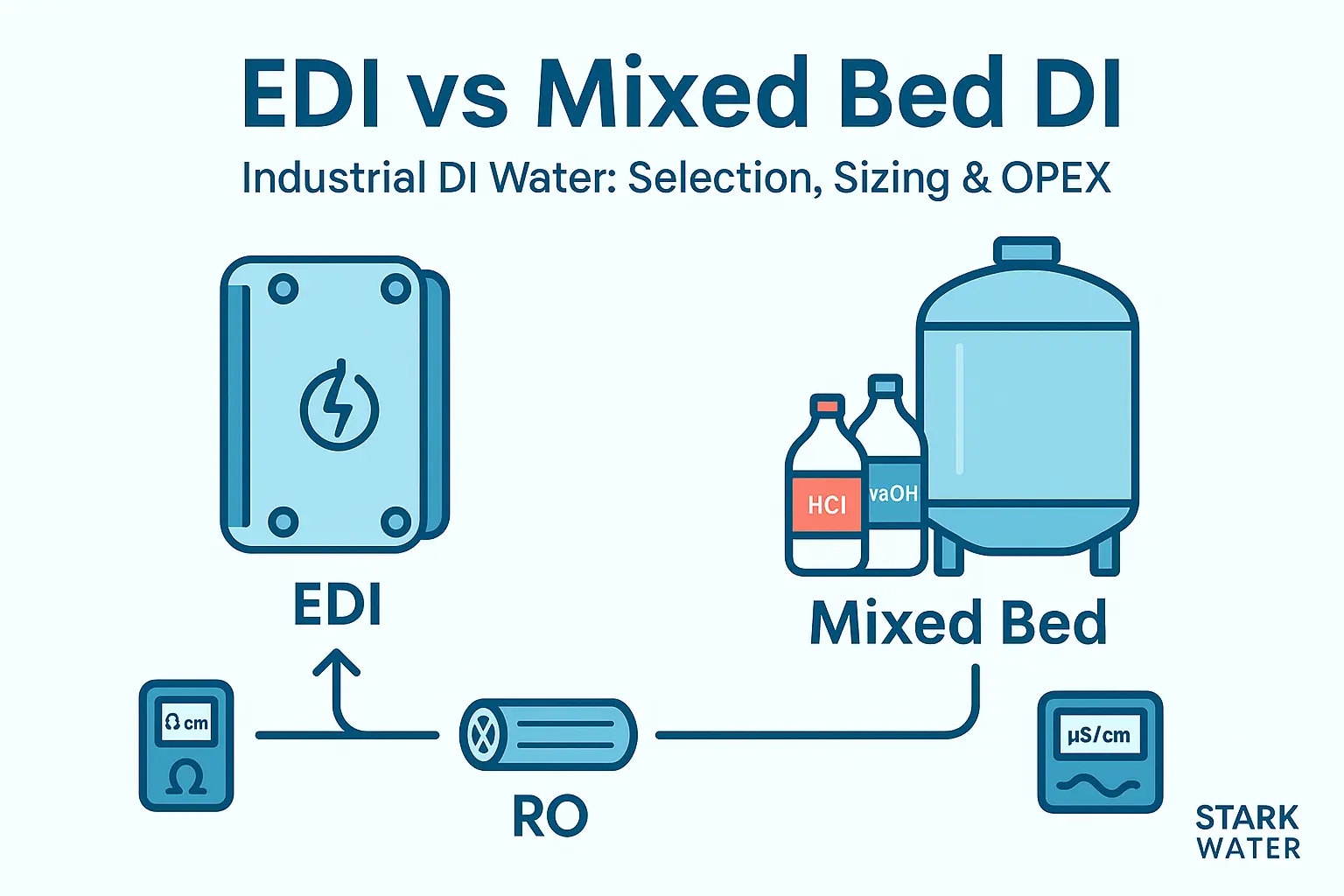

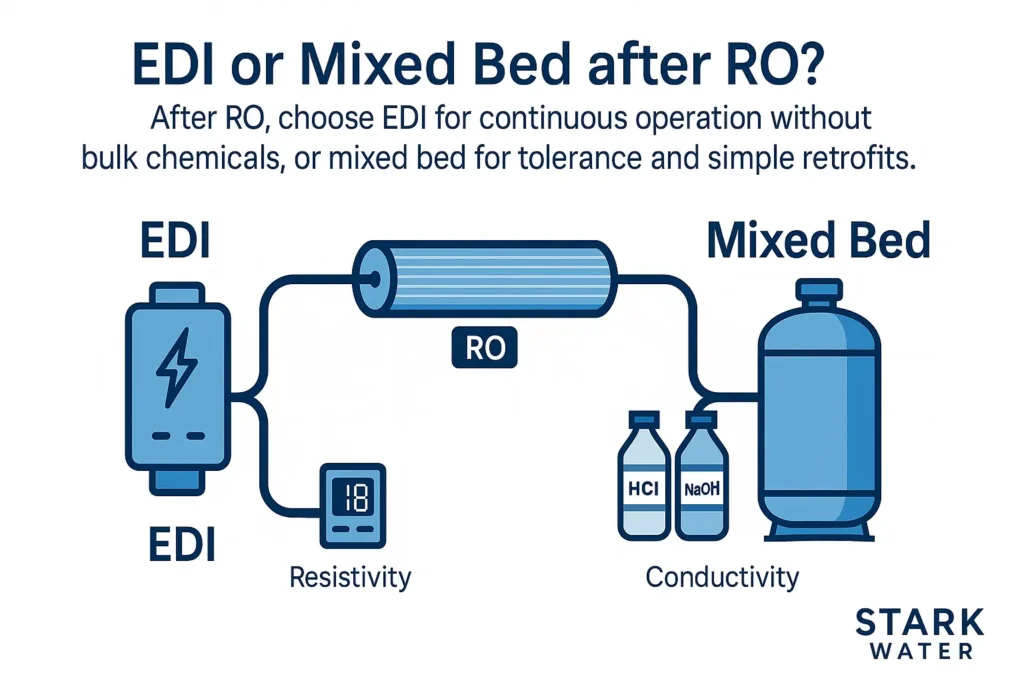

In most industrial trains, RO removes bulk salts first. A polisher then drives ionic content to the final target: EDI (electrodeionization) uses ion-exchange resins and membranes under an electric field for continuous polishing without bulk acid/caustic handling; a mixed bed uses separate cation/anion resins in one vessel that you regenerate with acid and caustic between runs.

Quality is specified as resistivity (MΩ·cm) lub conductivity (μS/cm). Quick conversion: conductivity (μS/cm) = 1 / resistivity (MΩ·cm). Many plants target 1–10 MΩ·cm; Type I lab water requires ~18 MΩ·cm with a polished loop.

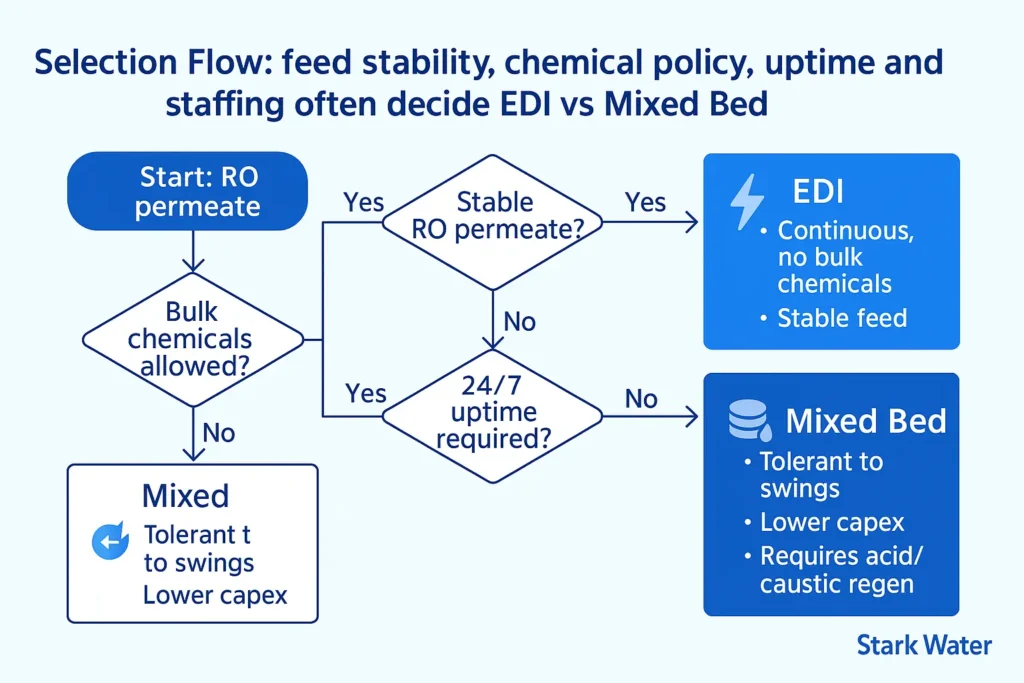

2) EDI vs Mixed Bed — Decision Matrix

| Criteria | EDI polishing | Mixed bed DI |

|---|---|---|

| Operating mode | Continuous, automated; no bulk chemicals | Batch; periodic acid/caustic regeneration and neutralization |

| Feed-water window | Best with stable RO permeate; low hardness/CO2/silica; low TOC | More tolerant to swings; handles intermittent operation well |

| Quality stability | Very stable resistivity at constant load | High resistivity achievable; may drift as resin exhausts |

| Uptime & staffing | High uptime; commissioning requires expertise | Simpler hardware; regeneration skills and safety training needed |

| OPEX | Electrical power; occasional CIP | Acid/caustic, rinse water, neutralization, PPE & handling |

| Footprint | Compact skid; power supply & controls | Vessels + chemical storage + neutralization system |

| When to prefer | Continuous production, limited chemical handling, tight specs | Retrofits, frequent stops/starts, wide feed variability, lower capex |

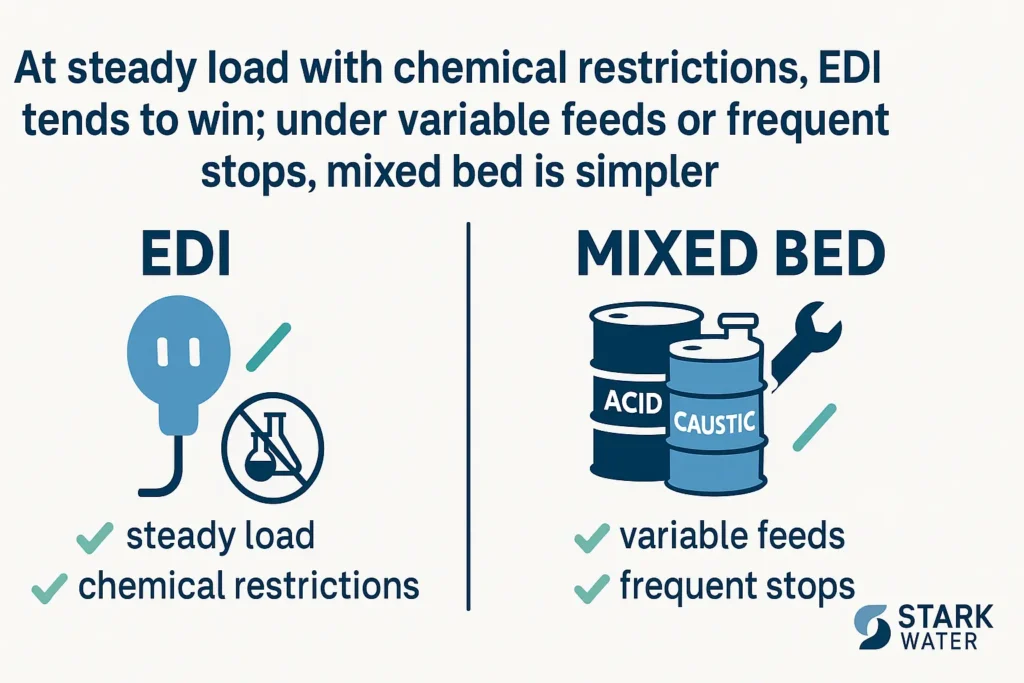

Rule of thumb: if your site restricts bulk chemicals or aims for continuous lights-out operation, pick EDI. If you need tolerance to irregular feeds, stop–start shifts, or want the lowest upfront cost, start with a mixed bed.

3) Sizing Rules & Quick Formulas

3.1 EDI Sizing

- Confirm RO permeate meets vendor window (low hardness; low CO2, silica and TOC; temperature factor applied).

- Select stacks by product flow (m³/h) and expected ionic load; request the vendor’s sizing sheet and add a seasonal safety margin.

- Provide bypass/recirculation and measure resistivity oraz flow at the skid outlet; alarm on deviations.

3.2 Mixed Bed Capacity (rule-of-thumb)

Express ionic load after RO as meq/L. Estimate resin volume for a target run time:

Resin volume (L) ≈ [meq/L × product flow (m³/h) × run time (h)] ÷ [resin capacity (eq/L)] × safety factor

Choose run time (e.g., 8–24 h) to align with shifts. Use the resin supplier’s capacity (depends on grade and regeneration regime).

3.3 Regeneration Chemical Estimate (general form)

Define required equivalents to restore the bed (from vendor). A general stoichiometric form is:

Acid volume (L) ≈ required eq ÷ acid normality (N) ÷ efficiency Caustic volume (L) ≈ required eq ÷ caustic normality (N) ÷ efficiency

“Efficiency” reflects practical overfeed and contact losses; confirm with your resin datasheet and SOP before ordering chemicals.

3.4 Quality Conversion (Resistivity ↔ Conductivity)

Resistivity (MΩ·cm) Conductivity (μS/cm)

Tip: conductivity (μS/cm) = 1 / resistivity (MΩ·cm).

4) OPEX, Footprint & Operations

- EDI OPEX: primarily electrical power; watch temperature/CO2–driven ionic load swings; run vendor-recommended CIP as needed.

- Mixed Bed OPEX: acid/caustic consumption, rinse water, neutralization system operation, PPE and handling/safety training.

- Downtime & variability: EDI prefers continuous duty; mixed beds tolerate stop–start operation and load spikes better.

- Compliance & safety: chemical storage with secondary containment, ventilation, eyewash/shower, and documented regeneration/neutralization SOPs.

5) Polishing, Storage & Distribution

- UV (254 nm) for microbial control; add 185 nm UV for TOC if SOP requires.

- 0.2 μm final filter before points of use or loop return.

- Use a stainless-steel storage tank with vent filter and spray ball; keep loop velocity high enough to maintain quality.

6) Materials & Instrumentation

- Pipes: UPVC/PP for pretreatment; SS316L or sanitary plastics downstream of polishing.

- Key meters: resistivity/conductivity (RO permeate, polisher outlet, loop return), TOC (if required), SDI, flow, and ΔP.

- Controls: PLC/HMI with interlocks on quality deviations and alarms; data logging for audits.

7) BOM Template & Related Products

- Pretreatment: MMF, GAC, softener or antiscalant dosing, cartridge filters

- RO skid: high-pressure pump, vessels/elements, instrumentation, CIP ports

- Polisher: EDI stacks lub mixed bed resin vessel with regeneration/CIP kit

- Polishing: UV 254 (option 185), 0.2 μm final filter

- Storage/loop: SS316L tank, recirculation pump, resistivity at outlet/return, TOC if needed

- Docs: P&ID, layout, FAT/SAT checklists, IQ/OQ templates

Related products & tools:

- RO membranes & housings, dosing pumps, activated carbon

- Stainless-steel contact & storage tanks

- Kalkulatory uzdatniania wody

8) FAQ

Is EDI always better than a mixed bed?

No. EDI is ideal when chemicals are restricted and operation is continuous. Mixed beds are cheaper to start and tolerate feed swings and stop–start duty.

How do I know my RO permeate is good enough for EDI?

Check hardness, CO2, silica and TOC against your vendor’s window. Stable temperature and load improve EDI performance and power efficiency.

What resistivity should I target after polishing?

Follow your SOP or industry guidance: many plants target 1–10 MΩ·cm; Type I lab water requires ~18 MΩ·cm and a polished loop.

Can I retrofit EDI to replace my mixed bed?

Yes — validate RO permeate window and utilities first, then size EDI stacks. Many sites keep a small mixed bed as emergency backup.

9) References (External)

Zespół inżynierów Stark Water — Field experience in RO, EDI and mixed-bed DI for electronics, labs, F&B and hospitality.