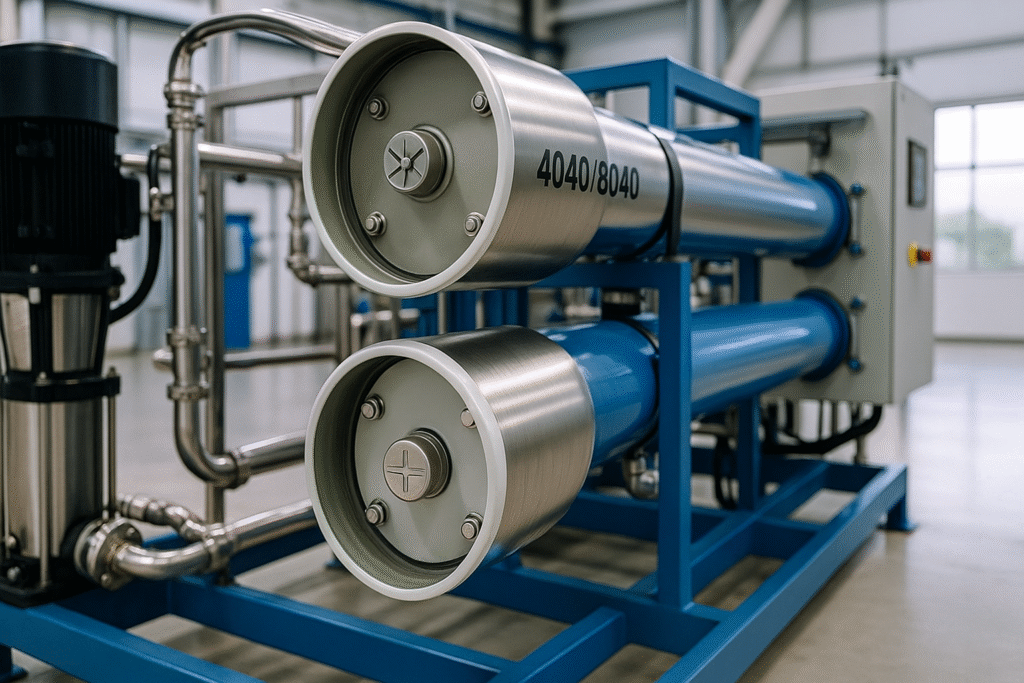

RO Sizing Wizard (4040/8040)

How this RO sizing calculator works

This free Kalkulator wielkości RO estimates the number of RO elements and the operating flux for 4040 oraz 8040 skids. You can edit membrane area per element, the design flux window, temperature and the target flow. The output is a quick element count only; final vessel counts, staging and pressure balance require vendor design software and verification on your site conditions.

Inputs explained

- Flow value — process flow at operating conditions (e.g., 1000 LPH). The tool accepts LPH or m3/h; make sure your unit matches the selector.

- Design flux window — min/max flux in Lmh (L/m²·h). Typical starting points:

- 4040: 10–25 Lmh (application and water quality dependent)

- 8040: 8–18 Lmh (lower flux for higher TDS/temperature)

- Element type — 4040 or 8040. (Only affects default area; you can overwrite.)

- Area per element — m² of active membrane area per element. Typical round numbers:

- 4040 ≈ 7.9 m² per element (varies by model)

- 8040 ≈ 37–41 m² per element (vendor/model dependent)

- Temperatura — °C at which the plant runs. Use the same reference temperature you will use for flux checks.

- Note — free text to remind future users what assumptions you used (salinity, recovery, pretreatment, etc.).

Quick formulas (what the widget does)

Flux in Lmh is defined as Flux = Flow ÷ Area. Rearranged for sizing, required area is Areq = Flow ÷ Flux. Element count is then N = ceil(Areq ÷ Aelem), where Aelem is membrane area per element. The tool reports the count at the selected flux within your window.

Worked example (illustrative)

Case: Flow = 1000 LPH (≈1 m³/h), temperature = 25 °C, flux window = 12–20 Lmh.

- Przy 18 Lmh: Areq = 1000 ÷ 18 ≈ 55.6 m².

- 4040 (7.9 m²): N ≈ 55.6 ÷ 7.9 ≈ 7 elements.

- 8040 (37 m²): N ≈ 55.6 ÷ 37 ≈ 2 elements (round up).

Note: This is element count only. Vessel count, staging (e.g., 2:1, 3:2), pressure drops and recovery splits must be checked in vendor tools with your salinity, SDI, temperature profile and chemical program.

Good practice & caveats

- Temperature & salinity shift flux — warm, low-viscosity water allows higher flux; high TDS or cold water need lower flux for the same fouling risk.

- Pretreatment matters — SDI ≤ 3, stable upstream UF/MMF and correct antiscalant/pH control extend membrane life and keep flux targets realistic.

- Element model ≠ generic area — always cross-check with the exact datasheet; some high-area elements exceed the nominal 37–41 m².

- Hydraulics — element count must translate into feasible vessel counts per stage, with acceptable permeate backpressure and concentrate velocity.

Related tools & reading

Continue sizing and economics with: RO OPEX Calculator, Kalkulator LSI oraz Kalkulator mieszania permeatu. Background on reverse osmosis is summarized here: Reverse osmosis (Wikipedia).

From estimate to design

Use this calculator to scope element count and operating flux ranges for 4040/8040 skids. Then validate in vendor design software with your recovery, temperature range, TDS, SDI, chemical program and materials. For configured package references, see our Rozwiązanie do uzdatniania wody RO 1000 LPH.

FAQ

What’s a sensible flux for 4040 vs 8040?

As a starting point, 4040 often runs at 10–25 Lmh and 8040 at 8–18 Lmh. Choose the lower end for high TDS, cold water or higher fouling risk, and confirm with vendor tools.

Does this calculator set vessel counts or staging?

No. It estimates element count only. Vessel counts, stage splits and hydraulics require vendor software and site-specific data.

Can I change the membrane area per element?

Yes. Enter the exact area from your datasheet (e.g., 7.9 m² for many 4040 models; 37–41 m² for 8040), then re-run sizing.

How does temperature affect sizing?

Higher temperature reduces viscosity and may allow higher flux; cold water usually needs lower flux to keep fouling risk manageable. Use the operating temperature for your checks.