Aplicações dos pré-filtros de aço inoxidável na filtragem de água

Aplicações dos pré-filtros de aço inoxidável na filtragem de águaAplicações dos pré-filtros de aço inoxidável na filtragem de água

Enhance your water filtration system with Stark Water’s Stainless Steel Prefilter. Designed for robust performance, this durable stainless steel prefilter provides essential initial filtration, effectively removing larger particles and sediment to protect downstream equipment and improve overall water quality in various industrial and domestic applications.

Descrição do produto

Effective pre-filtration is the cornerstone of any efficient and long-lasting water treatment system. It acts as the crucial first line of defense, safeguarding more sensitive and expensive purification stages from premature wear and fouling. The Stark Water Stainless Steel Prefilter is specifically engineered to excel in this vital role, providing robust, reliable, and high-performance initial filtration for a wide range of water filtration applications.

The Indispensable Role of a Stainless Steel Prefilter in Water Filtration

A stainless steel prefilter is designed to efficiently remove larger suspended solids, sediment, rust particles, and other coarse impurities from raw water. By doing so, it significantly reduces the turbidity and particulate load on subsequent filtration stages, such as cartridge filters, activated carbon filters, UV sterilizers, and especially sensitive membrane systems like Reverse Osmosis (RO) and Ultrafiltration (UF). This pre-filtration step is critical for:

- Extending Equipment Lifespan: Protecting pumps, valves, and finer filters from abrasion, clogging, and damage caused by larger particles.

- Improving System Efficiency: Ensuring optimal performance of downstream components by presenting them with cleaner water.

- Reducing Maintenance Costs: Minimizing the frequency of cleaning or replacement for more expensive filters and membranes.

- Enhancing Overall Water Quality: Contributing to cleaner, clearer water from the outset of the treatment process.

Superior Construction with High-Grade Stainless Steel

The choice of material for a prefilter is paramount, especially given its role in handling raw, often heavily contaminated water. Our prefilters are meticulously constructed from high-grade stainless steel (typically SUS304 or SUS316L). This material offers exceptional durability, corrosion resistance, and structural integrity, allowing the filter to withstand high operating pressures and harsh environmental conditions. Unlike plastic alternatives, stainless steel provides superior resistance to temperature fluctuations, UV degradation, and a broader range of chemical compatibilities, ensuring a long operational lifespan and reliable performance even in demanding industrial settings. The robust construction also contributes to the prefilter’s ability to be easily cleaned and maintained, making it a sustainable and cost-effective long-term solution.

Versatile Design for Diverse Applications

The Stark Water Stainless Steel Prefilter is designed for versatility, compatible with various flow rates and pressure demands. It typically features a mesh or screen-type filtration element (e.g., woven wire mesh or wedge wire screen) capable of filtering down to a specific micron rating (e.g., 50 microns to 200 microns, or finer depending on specific design). The ease of backwashing or manual cleaning of the filter element ensures quick maintenance and minimal downtime. Whether installed as a standalone unit for initial protection or integrated into a multi-stage water treatment plant, its robust design and efficient filtration capabilities make it an indispensable component across a wide array of industrial, commercial, and even large residential water filtration applications.

Parâmetro do produto

| Parâmetro | Especificação / Opções de personalização |

|---|---|

| Foco na palavra-chave principal | Stainless steel prefilter design and capabilities. |

| Filter Type | Prefilter (Mesh Screen or Wedge Wire Element) |

| Material Construction | High-grade Stainless Steel (SUS304 or SUS316L, specified based on corrosion resistance needs). |

| Filtration Rating | Customizable, typically ranging from 50 micron to 200 micron (or finer/coarser as required). |

| Design Type | Y-Strainer type, T-type, or straight-through inline design. Backwashable options available. |

| Inlet/Outlet Connections | Threaded (NPT, BSPT) or Flanged (ANSI, DIN, JIS standards), common sizes from ½” to 6″ or larger. |

| Max. Operating Pressure | Typically 1.0 MPa (10 Bar / 145 PSI) to 1.6 MPa (16 Bar / 232 PSI), customizable for higher pressures. |

| Max. Operating Temperature | Up to 95°C (203°F), dependent on sealing materials. |

| Surface Finish | Polished or Pickled/Passivated for enhanced corrosion resistance. |

| Sealing Material | EPDM, Viton (FKM), Buna-N (NBR) (selected based on chemical compatibility and temperature). |

| Flow Rate Capacity | Varies significantly based on size, connection, and micron rating (e.g., from 1 m³/hr to 500+ m³/hr). |

| Cleaning Method | Manual flush/backwash, brush cleaning, or automated self-cleaning systems available. |

| Installation | Vertical or horizontal installation, depending on model. |

Setor aplicável

- Industrial Water Treatment: Essential for pre-filtration in factories, power plants, and large-scale water treatment facilities, protecting expensive RO membranes, UF systems, EDI units, ion exchange beds, and pumps from suspended solids, grit, and large particulate matter.

- Municipal Water Systems: Used in raw water intake lines or before primary treatment stages to remove larger debris, protecting pumps and preventing clogging of filtration media.

- Food & Beverage Industry: Filters process water for beverage production, food washing, and pre-filtration for ingredient water, ensuring initial clarity and hygiene.

- Chemical Processing: Protects pumps and sensitive equipment from particles in process water, cooling water, and various chemical solutions.

- HVAC & Cooling Towers: Removes suspended solids from circulating cooling water, preventing fouling, improving heat exchange efficiency, and extending the lifespan of cooling systems.

- Agricultural & Irrigation Systems: Essential for filtering irrigation water (e.g., from rivers, wells) to prevent clogging of sprinklers, drip lines, and other irrigation components.

- Pharmaceuticals (Utility Water): Used for pre-filtering utility water lines to protect downstream purification systems and general facility equipment.

- Textile & Dyeing Industry: Filters process water used in dyeing and washing, preventing impurities from affecting fabric quality and color.

- Mining & Metals Industry: For primary filtration of process water, washdown water, and wastewater containing heavy suspended solids.

- Residential (Large Scale/Well Water): Ideal for large homes or properties with private well water systems to remove sand, silt, and rust before the water enters the main plumbing system.

Vantagem Um

Vantagem DOIS

Produtos relacionados

Produtos Relacionados

-

Purificador de água para uso doméstico

STARK 2000L Purificador de água para uso doméstico Caixa de filtro de água com purificador de cartucho de ultrafiltração Pvdf Uf

Adicionar ao orçamento -

Purificador de água para uso doméstico

Sistema de filtragem de água de pré-tratamento por osmose inversa Stark 500LPH

Adicionar ao orçamento -

Purificador de água para uso doméstico

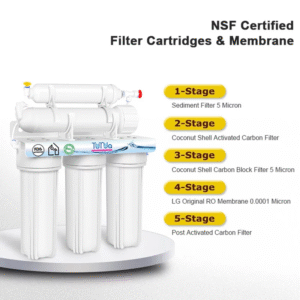

75GPD Reverse Osmosis Household Water Purifier | 5-Stage Water Filter Purifier

Adicionar ao orçamento

FAQ

Q1: Quanto tempo dura o sistema de osmose inversa?

A vida útil de um sistema de osmose inversa depende da qualidade da água e da manutenção. Normalmente, a membrana dura 2-3 anos, enquanto o sistema em si pode durar mais de 10 anos com os cuidados adequados.

Q2: O sistema pode ser personalizado com base nas diferentes condições da água?

Sim, todos os nossos sistemas são totalmente personalizáveis. Analisamos o seu relatório de água e as necessidades da aplicação antes de fornecer soluções à medida.

Q3: A que normas obedece o equipamento STARK?

Os nossos produtos estão em conformidade com a norma CE, ISO 9001, e podem ser concebidos para cumprir regulamentos regionais específicos ou normas industriais, mediante pedido.

Q4: Qual é o prazo de entrega dos sistemas STARK RO?

Os sistemas standard são enviados no prazo de 7 a 15 dias. Para encomendas personalizadas, o prazo de entrega pode prolongar-se até 20-25 dias, dependendo da complexidade.

Q5: Prestam assistência técnica ou orientação para a instalação?

Sim. Fornecemos documentação técnica completa, orientação remota através de vídeo e podemos enviar engenheiros internacionalmente mediante pedido.

Q6: O que está incluído no vosso orçamento?

O nosso orçamento inclui o sistema RO completo, o painel de controlo, as bombas, as unidades de pré-tratamento e todos os acessórios necessários. As ferramentas de instalação e as peças sobresselentes podem ser incluídas mediante pedido.