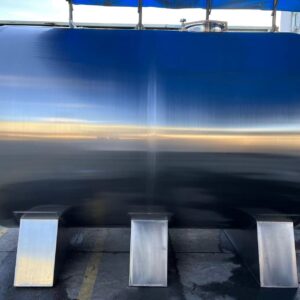

STARK 1T&100T Customized Stainless Steel Water Tank Odm Stainless Steel Water Tank for water treatment filter

Secure a precisely tailored and hygienic water storage solution with STARK’s 1T & 100T Customized Stainless Steel Water Tank. As an ODM stainless steel water tank provider, we engineer bespoke tanks for diverse water treatment filter applications, ensuring optimal integration, durability, and purity across a wide range of industrial capacities.

Descrição do produto

In modern water treatment and industrial processes, the need for water storage often extends beyond standard off-the-shelf solutions, demanding precise dimensions, specific functionalities, and adherence to stringent material standards. The STARK 1T & 100T Customized Stainless Steel Water Tank addresses this exact need, providing a versatile, durable, and hygienic storage solution meticulously engineered to your unique requirements. This is more than just a tank; it’s a critical component designed to optimize your water treatment filter systems and broader liquid handling operations.

Customized Stainless Steel Water Tank: Tailored from 1T to 100T

Our core expertise lies in providing a truly customized stainless steel water tank, capable of meeting an extensive range of capacities, from 1 metric ton (1,000 liters or 1 m³) up to 100 metric tons (100,000 liters or 100 m³) and beyond. This vast customizable range ensures that whether you need a compact buffer tank for a specialized process or a massive reservoir for a municipal water treatment filter plant, we can design and fabricate a tank that fits precisely. Our customization extends to:

- Dimensões específicas: Tailored diameters, heights, and shapes to optimize space utilization.

- Connection Types & Placement: Precise sizing and location of inlets, outlets, drains, vents, and overflow pipes (e.g., flanged, threaded, sanitary Tri-Clamp).

- Internal & External Finishes: Customized polishing (from standard to mirror-polished Ra < 0.4 μm), passivation, or specialized coatings for specific hygiene levels or corrosive resistance.

- Caraterísticas integradas: Custom cut-outs for instruments (level sensors, temperature probes), agitation systems, heating/cooling jackets, and internal baffles.

- Grau do material: Choice between SUS304 (standard) and SUS316L (for enhanced corrosion resistance against chlorides).

This bespoke engineering ensures seamless integration and optimized performance for your specific water treatment filter applications.

ODM Stainless Steel Water Tank for Water Treatment Filter Systems

As an ODM (Original Design Manufacturer) stainless steel water tank provider, STARK offers unparalleled expertise in designing and manufacturing tanks specifically for water treatment filter systems. These tanks are commonly used as:

- Purified Water Storage: Holding treated water post-RO, UF, or DI systems before distribution.

- Filter Media Tanks: Housing granular media for multi-media filters, activated carbon filters, or ion exchange resins.

- Chemical Dosing Tanks: Storing and preparing chemical solutions for pre-treatment or disinfection.

- Backwash/CIP Tanks: Holding water or solutions for filter backwashing and Clean-in-Place (CIP) processes.

- Raw Water Buffer Tanks: Providing temporary storage of influent water for steady plant operation.

The inherent hygiene and corrosion resistance of stainless steel make it the ideal material for these applications, ensuring the integrity of the water and the longevity of the tank even with various water chemistries or exposure to cleaning agents. Our ODM capability means we can provide fully integrated tank solutions tailored to complement your existing or new water treatment filter infrastructure.

Durability, Hygiene, and Long-Term Value

Every STARK customized stainless steel water tank is built for exceptional durability and hygiene. The robust construction ensures resistance to pressure, temperature variations, and continuous industrial use. This commitment to quality, combined with our ability to customize, delivers a reliable, long-lasting asset that maximizes operational efficiency, minimizes maintenance needs, and provides a cost-effective solution for your diverse water treatment and storage requirements.

Parâmetro do produto

STARK’s 1T & 100T Customized Stainless Steel Water Tank is precisely engineered as an ODM stainless steel water tank for water treatment filter applications. Here are its key technical specifications:

| Parâmetro | Especificação / Opções de personalização |

|---|---|

| Foco na palavra-chave principal | customized stainless steel water tank design and capabilities. |

| Capacity Range | Customizable from 1,000 Liters (1T / 1 m³) to 100,000 Liters (100T / 100 m³) or more. |

| Material de construção | Stainless Steel (SUS304 standard, SUS316L optional for enhanced corrosion resistance). Duplex SS for highly aggressive environments (custom). |

| Tipo de desenho | Vertical or Horizontal Cylindrical. Customizable head types (dished, conical, flat) and bottom (dished, conical, flat). Can be single-wall, jacketed, or insulated. |

| Acabamento da superfície interna | Customizable: Polished (e.g., Ra < 0.6 μm) or mirror-polished (Ra < 0.4 μm) for hygiene; electro-polishing available. |

| Acabamento da superfície exterior | Satin polished, Matt finish, #2B finish, or custom painting. |

| Máx. Pressão de funcionamento | Atmospheric to pressurized (e.g., 0-1.0 MPa / 0-10 Bar), designed to client’s pressure requirements. |

| Gama de temperaturas de funcionamento | Customizable, from cold (-20°C) to hot (up to 200°C). |

| Aquecimento/arrefecimento (opcional) | Jacketed (dimple, coil, or full), internal coils, or electric heating elements for precise temperature control. |

| Agitação (opcional) | Top-mounted or side-mounted agitators with sanitary seals for mixing applications. |

| Ligações/Acessórios | Customizable inlets, outlets, drains, vents, overflows. Standard threaded, flanged, or sanitary Tri-Clamp connections. Includes ports for level, temperature, pressure, pH sensors. Manhole/handhole, sight glass. |

| Pernas de apoio | Pernas ajustáveis em aço inoxidável com almofadas de chão; ou suporte de saia. |

| Caraterísticas higiénicas | Soldadura sanitária (sem fendas), drenagem completa, compatibilidade CIP/SIP (se aplicável). |

| Conformidade com as normas | Designed and manufactured according to relevant industry standards (e.g., ASME, CE, ISO, FDA/GMP where applicable). |

| Supply Model | ODM (Original Design Manufacturer) capabilities for tailored solutions. |

Setor aplicável

STARK’s 1T & 100T Customized Stainless Steel Water Tank, as an ODM stainless steel water tank, is a highly versatile and essential asset for various industries requiring bespoke, hygienic, and reliable water storage solutions for water treatment filter applications. Its custom design and robust construction make it ideal for:

- Industrial Water Treatment Plants: Custom-designed as purified water storage tanks (post-RO/UF/DI), filter media tanks (e.g., multi-media, carbon, ion exchange), chemical mixing/dosing tanks, or backwash/CIP solution tanks, for capacities ranging from auxiliary to very large-scale.

- Pharmaceutical & Biotechnology: For storing Purified Water (PW), Water for Injection (WFI), sterile solutions, or process water where hygiene, material compatibility (e.g., 316L SS), and precise temperature control are critical, in compliance with GMP guidelines.

- Food & Beverage Industry: Custom tanks for hygienic storage of process water, ingredient water, CIP solutions, or finished liquid products (e.g., milk, juices, beer), ensuring product safety, taste integrity, and extended shelf life.

- Chemical Manufacturing: For storing purified water for chemical formulations, or holding various chemical solutions where precise material compatibility, heating/cooling, or mixing is required.

- Electronics & Semiconductor Manufacturing: Custom tanks for storing ultra-pure water (UPW) used in high-tech manufacturing processes, where absolute purity and crevice-free design are essential.

- Power Generation: Customized tanks for boiler feed water, condensate, or cooling tower make-up water, optimizing water quality within the plant’s specific needs.

- Wastewater Treatment & Reuse: Bespoke tanks for holding treated effluent before discharge or reuse, or for chemical preparation within wastewater treatment processes.

- Laboratories & Research Facilities: Custom tanks for storing various grades of purified water, reagents, or specialized solutions, designed to fit unique lab layouts and experimental needs.

- Cosmetics & Personal Care: For hygienic storage and processing of purified water and ingredients, ensuring product purity and stability.

- Agricultural (Specific): Custom tanks for preparing or storing purified/treated water for hydroponics, specialized irrigation, or livestock, where precise water quality is essential.

Vantagem Um

Vantagem DOIS

Produtos relacionados

Produtos Relacionados

- Tanque de água esterilizada

Fornecedor chinês por atacado personalizado 304 tanque de água quente de aço inoxidável

Adicionar ao orçamento - Tanque de água esterilizada

Customized Water Tank Stainless Steel Heat Insulation Materials

Adicionar ao orçamento

FAQ

Q1: Quanto tempo dura o sistema de osmose inversa?

A vida útil de um sistema de osmose inversa depende da qualidade da água e da manutenção. Normalmente, a membrana dura 2-3 anos, enquanto o sistema em si pode durar mais de 10 anos com os cuidados adequados.

Q2: O sistema pode ser personalizado com base nas diferentes condições da água?

Sim, todos os nossos sistemas são totalmente personalizáveis. Analisamos o seu relatório de água e as necessidades da aplicação antes de fornecer soluções à medida.

Q3: A que normas obedece o equipamento STARK?

Os nossos produtos estão em conformidade com a norma CE, ISO 9001, e podem ser concebidos para cumprir regulamentos regionais específicos ou normas industriais, mediante pedido.

Q4: Qual é o prazo de entrega dos sistemas STARK RO?

Os sistemas standard são enviados no prazo de 7 a 15 dias. Para encomendas personalizadas, o prazo de entrega pode prolongar-se até 20-25 dias, dependendo da complexidade.

Q5: Prestam assistência técnica ou orientação para a instalação?

Sim. Fornecemos documentação técnica completa, orientação remota através de vídeo e podemos enviar engenheiros internacionalmente mediante pedido.

Q6: O que está incluído no vosso orçamento?

O nosso orçamento inclui o sistema RO completo, o painel de controlo, as bombas, as unidades de pré-tratamento e todos os acessórios necessários. As ferramentas de instalação e as peças sobresselentes podem ser incluídas mediante pedido.