STARK UF PVDF Hollow fiber UF membrane water filter UltraFiltration Membrane OEM

STARK UF PVDF Hollow fiber UF membrane water filter UltraFiltration Membrane OEMSTARK UF PVDF Hollow fiber UF membrane water filter UltraFiltration Membrane OEM

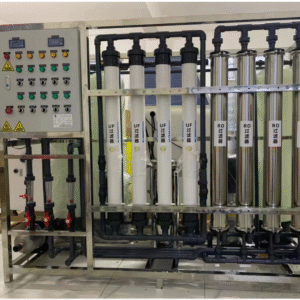

Achieve superior water purification with Stark Water’s STARK UF PVDF Hollow Fiber UF Membrane Water Filter. This high-performance uf membrane, crafted from durable PVDF, offers exceptional filtration efficiency for various industrial and commercial applications, available for OEM customization to meet your specific needs.

Descrição do produto

In the realm of advanced water treatment, the choice of membrane material significantly impacts system performance, longevity, and resistance to challenging feedwater conditions. The Stark Water STARK UF PVDF Hollow Fiber UF Membrane Water Filter represents a leading solution in ultrafiltration technology, distinguished by its premium PVDF (Polyvinylidene Fluoride) construction. This advanced uf membrane is engineered to deliver superior separation efficiency and robust durability, making it an ideal choice for a wide array of demanding industrial and commercial water purification needs.

The Superiority of PVDF in UF Membrane Technology

The defining feature of this product is its high-quality **PVDF (Polyvinylidene Fluoride)** material. PVDF is celebrated in membrane technology for its exceptional properties, which directly translate to superior performance in real-world applications:

- Excellent Chemical Resistance: PVDF membranes exhibit remarkable resistance to a broad range of chemicals, including strong acids, bases, and oxidizing agents. This makes them highly suitable for treating aggressive industrial wastewaters or applications where chemical cleaning agents are frequently used.

- High Mechanical Strength: PVDF provides outstanding physical durability, allowing the hollow fibers to withstand higher operating pressures and frequent backwashing cycles without breakage, ensuring a longer lifespan.

- Hydrophilicity: While inherently hydrophobic, specialized treatment during manufacturing enhances PVDF’s hydrophilicity. This improves its wettability, reduces fouling potential, and ensures stable flux rates during filtration.

- Broad Temperature Tolerance: PVDF membranes can operate efficiently across a wider range of temperatures, offering flexibility in various industrial processes.

This inherent strength and resilience of the PVDF material ensure that our UltraFiltration Membrane delivers consistent, high-quality permeate even in challenging environments where other membrane types might degrade.

High-Efficiency Hollow Fiber UF Membrane Water Filter

The **hollow fiber** configuration further enhances the efficiency and compactness of this uf membrane water filter. Thousands of tiny, porous PVDF tubes are bundled together, providing an expansive surface area within a compact module. This design facilitates efficient filtration, effectively removing suspended solids, turbidity, bacteria, viruses, and protozoa (like Cryptosporidium and Giardia) with high rejection rates. Operating at low transmembrane pressures, these membranes contribute to energy efficiency. Their robust structure supports effective backwashing and air scouring techniques, simplifying cleaning cycles, reducing operational downtime, and significantly extending the membrane’s service life.

OEM Capabilities for Tailored Filtration Solutions

As a specialized **OEM (Original Equipment Manufacturer)**, Stark Water offers extensive customization capabilities for our **UF membrane** products. This means we can supply Ultrafiltration membranes precisely tailored to your specific requirements, including custom module dimensions, connection types, flux rates, and specific potting materials. Whether you are a system integrator, a water treatment project developer, or an equipment manufacturer, our OEM services ensure that you receive membranes that perfectly fit your unique system design, optimize performance, and even carry your own branding. This bespoke approach guarantees seamless integration and optimal efficiency for your filtration solutions.

Parâmetro do produto

| Parâmetro | Especificação / Opções de personalização |

|---|---|

| Foco na palavra-chave principal | Uf membrane design and performance. |

| Membrane Material | PVDF (Polyvinylidene Fluoride) – High chemical and mechanical resistance. |

| Tipo de membrana | Ultrafiltration (UF) Membrane, Hollow Fiber Configuration. |

| Pore Size | Typically 0.01 μm to 0.1 μm (e.g., 0.02 μm, 0.03 μm), specified based on application. |

| Module Configurations | Standard sizes (e.g., 4-inch, 6-inch, 8-inch diameter and various lengths), custom dimensions available as OEM. |

| Operating Mode | Outside-in or Inside-out flow. Can be operated in dead-end or cross-flow filtration modes. |

| Operating Pressure | Typically 0.05 – 0.2 MPa (0.5 – 2 Bar / 7 – 29 PSI). Low pressure operation. |

| Maximum Transmembrane Pressure (TMP) | Customizable, often around 0.3 MPa (3 Bar / 43 PSI). |

| pH Range (Continuous Operation) | 2 – 10. |

| pH Range (Short-Term Cleaning) | 1 – 13 (reflecting PVDF’s excellent chemical resistance). |

| Max. Free Chlorine Tolerance | < 100 ppm (short term); < 1 ppm (continuous) – Higher tolerance than some other UF materials. |

| Temperatura de funcionamento | 5°C – 45°C (41°F – 113°F). |

| Turbidity Reduction | >99% |

| Bacteria/Virus Removal | >99.9999% (log 6 reduction or higher). |

| OEM Design/Customization | Custom module dimensions, connection types, specific potting compounds, private labeling possible. |

Setor aplicável

- Wastewater Treatment & Reuse: Particularly effective in Membrane Bioreactor (MBR) systems for municipal and industrial wastewater treatment, producing high-quality effluent due to PVDF’s resistance to organic fouling and harsh cleaning chemicals.

- Industrial Process Water: Provides clean process water in industries where chemical resistance is crucial, such as chemical manufacturing, textile dyeing, and pulp & paper, for boiler feed, cooling towers, and general utility.

- Reverse Osmosis (RO) Pre-treatment: Offers superior pre-filtration for RO systems, especially when dealing with challenging feedwater that may contain high suspended solids, colloids, or requires aggressive cleaning, protecting sensitive RO membranes from fouling and extending their lifespan.

- Drinking Water Treatment: Essential for municipal waterworks and private water supplies for effective removal of turbidity, suspended solids, bacteria, viruses, and protozoa, providing safe potable water.

- Food & Beverage Industry: Used for clarification of juices, wine, beer, and other beverages; process water filtration; and pre-treatment for sterile filtration, especially when frequent chemical cleaning is required.

- Pharmaceuticals & Biotechnology: For purification of process water, pre-filtration for sterile processes, and clarification in bioprocessing, benefiting from PVDF’s chemical compatibility and hygiene.

- Oil & Gas Industry: Applied in produced water treatment, frac water filtration, and other applications where the water may contain oil, suspended solids, or harsh chemicals.

- Metal Finishing Industry: Clarification of process solutions, rinse waters, and wastewater to remove suspended solids and heavy metals, benefiting from chemical resistance.

- Mining Operations: For treating process water and wastewater containing high levels of suspended solids and various minerals.

Vantagem Um

Vantagem DOIS

Produtos relacionados

Produtos Relacionados

-

Sistema de dessalinização da água do mar

STARK Preço competitivo de fábrica Sistema de dessalinização de água do mar 2000LPH sistema de filtro de tratamento de água

Adicionar ao orçamento -

Equipamento de ultrafiltração

Reverse Osmosis ystem Water UF Equipment Manufacturer

Adicionar ao orçamento

FAQ

Q1: Quanto tempo dura o sistema de osmose inversa?

A vida útil de um sistema de osmose inversa depende da qualidade da água e da manutenção. Normalmente, a membrana dura 2-3 anos, enquanto o sistema em si pode durar mais de 10 anos com os cuidados adequados.

Q2: O sistema pode ser personalizado com base nas diferentes condições da água?

Sim, todos os nossos sistemas são totalmente personalizáveis. Analisamos o seu relatório de água e as necessidades da aplicação antes de fornecer soluções à medida.

Q3: A que normas obedece o equipamento STARK?

Os nossos produtos estão em conformidade com a norma CE, ISO 9001, e podem ser concebidos para cumprir regulamentos regionais específicos ou normas industriais, mediante pedido.

Q4: Qual é o prazo de entrega dos sistemas STARK RO?

Os sistemas standard são enviados no prazo de 7 a 15 dias. Para encomendas personalizadas, o prazo de entrega pode prolongar-se até 20-25 dias, dependendo da complexidade.

Q5: Prestam assistência técnica ou orientação para a instalação?

Sim. Fornecemos documentação técnica completa, orientação remota através de vídeo e podemos enviar engenheiros internacionalmente mediante pedido.

Q6: O que está incluído no vosso orçamento?

O nosso orçamento inclui o sistema RO completo, o painel de controlo, as bombas, as unidades de pré-tratamento e todos os acessórios necessários. As ferramentas de instalação e as peças sobresselentes podem ser incluídas mediante pedido.