Reading time: 12–18 minutes · Audience: RO designers, process engineers, EPCs, plant operators

Security filter sizing is often treated as a “minor” detail in RO pretreatment. In reality, the security (cartridge) filter is the last protection before the high-pressure pump and membranes. An undersized filter will foul quickly, starve the pump and trigger RO trips; an oversized or poorly designed vessel adds cost and still may not meet code thickness.

This guide walks through a complete example of security filter sizing for one RO train: from design flow and cartridge count, to housing diameter, working differential pressure, wall thickness and nozzle sizing. All the calculations are shown so you can adapt the workflow to your own projects.

Why Security Filters Matter Before RO

The security filter is installed just upstream of the RO high-pressure pump. Its primary mission is to catch any particles that escape upstream processes such as clarification, media filtration, ultrafiltration or cartridge filters on individual units.

- Protect the high-pressure pump: solids can erode impellers and seats, causing vibration and reduced efficiency.

- Protect RO membranes: large particles and slug loads can plug feed channels, increase pressure drop and cause irreversible fouling.

- Define a clear “sacrificial” element: cartridges are cheap and easy to replace; RO elements are not.

Because of this, a professional security filter sizing exercise must address both the hydraulic side (flow per cartridge, pressure drop) and the mechanical side (shell and head thickness, nozzle diameter and layout).

Design Basis and Operating Conditions

In this worked example, we size a horizontal security filter for one RO train with the following design basis:

Process conditions

- Design feed flow to the RO train: Q = 174 m³/h

- Normal operating pressure upstream of the filter: about 0.5 MPa (gauge)

- Water temperature: 5–35 °C

- Water quality: clarified and pre-filtered, SDI within RO specification

Cartridge assumptions

- Cartridge type: standard DOE (double open end), 40″ length, rated for the design pressure

- Micron rating: typically 5 µm or 10 µm depending on RO vendor requirement

- Recommended clean-water flow per cartridge: q = 50 m³/h (example value for calculation)

- Maximum allowable differential pressure per cartridge: 1.0 MPa

With these assumptions set, we can start the step-by-step sizing procedure.

Step 1 — Cartridge Count and Housing Diameter

1.1 Cartridge count from design flow

The first step in security filter sizing is to determine how many cartridges are required at the design flow.

Use the basic relation:

m = Q / q

- Q = total design flow through the filter (m³/h)

- q = design flow per cartridge (m³/h)

- m = required number of cartridges (pcs)

For this example:

- Q = 174 m³/h

- q = 50 m³/h per cartridge

Then:

m = 174 / 50 = 3.48 → round up to 4 cartridges

After rounding, the actual flow per cartridge becomes:

qactual = 174 / 4 ≈ 43.5 m³/h

Always compare this value with the cartridge manufacturer’s recommended range. If you are above the recommended flux, increase the cartridge count; if you are well below, you may be able to reduce the count.

1.2 Choosing housing diameter and layout

With four cartridges, we select a standard housing diameter that comfortably arranges them in a single row. In this example, we choose an internal diameter:

Di = 450 mm

Layout decisions:

- Orientation: horizontal installation for easier cartridge replacement and lower working height.

- End closure: flanged or swing-bolt quick opening head, with clear axial space to pull cartridges.

- Nozzles: feed and outlet nozzles on the shell, with a vent on the top of the head and a drain at the low point.

Step 2 — Differential Pressure and Replacement Criteria

Cartridges are consumables. Instead of pushing them to the maximum possible differential pressure (ΔP), we operate them at a conservative limit that protects both the housing and the downstream RO.

2.1 Design and operating ΔP

- Maximum allowable ΔP per cartridge: 1.0 MPa (from datasheet)

- Recommended control ΔP across the housing: 0.10 MPa (clean at <0.02 MPa, change-out at 0.10 MPa)

This lower operating ΔP ensures:

- More stable feed pressure to the RO high-pressure pump.

- Reduced risk of cartridge bypass or structural collapse.

- Easier trend analysis of upstream fouling and pretreatment performance.

2.2 Instrumentation for DP control

To implement a robust change-out strategy, the housing should include:

- Pressure gauge or transmitter at the inlet nozzle.

- Pressure gauge or transmitter at the outlet nozzle.

- Differential pressure transmitter or local indicator (optional but recommended).

Typical operating practice:

- Clean reference: record ΔP just after cartridge replacement.

- Warning alarm: at 70–80% of the change-out ΔP (e.g. 0.07–0.08 MPa).

- Change-out: at 0.10 MPa ΔP or when RO feed pressure reaches a predefined limit.

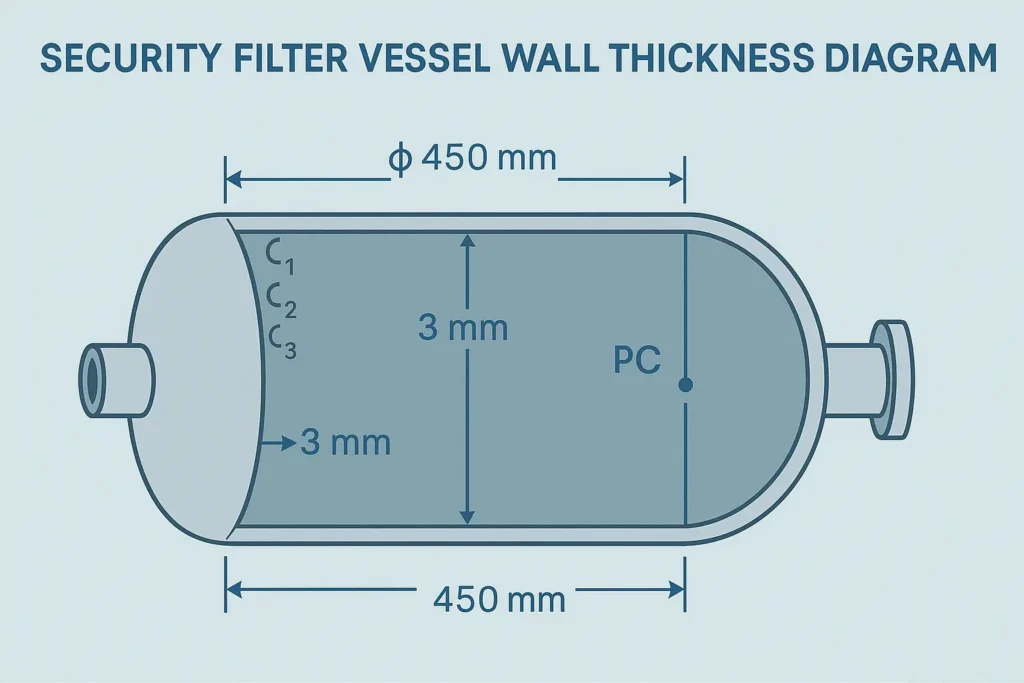

Step 3 — Mechanical Design: Shell & Head Wall Thickness

Once the hydraulic design is set, the housing must be checked mechanically. Here we take a simplified thin-wall design approach suitable for low-pressure stainless steel vessels. Final design should be verified against the applicable pressure vessel code in your region.

3.1 Design pressure, allowable stress and joint efficiency

For this example, we define:

- Working pressure, PG = 0.5 MPa

- Design pressure, PS = 1.1 × PG = 0.55 MPa

- Calculation pressure, PC = PS + 0.1 = 0.65 MPa

- Hydrotest pressure, PJ ≈ 1.25 × PS = 0.7 MPa

- Allowable stress for stainless steel at ≤100 °C, [σ] = 137 MPa

- Longitudinal weld joint efficiency, φ = 0.60 (single-side butt weld with spot radiography)

- Internal diameter, Di = 450 mm

3.2 Cylindrical shell thickness

For a thin-walled cylinder under internal pressure, the required theoretical thickness S0 is:

S0 = (PC · Di) / (2 · [σ] · φ − PC)

Substituting the values:

- PC = 0.65 MPa

- Di = 450 mm

- [σ] = 137 MPa

- φ = 0.60

We obtain a theoretical shell thickness of approximately:

S0 ≈ 1.8 mm

Next, we add allowances:

- Plate negative tolerance: C1 = 0.18 mm

- Corrosion allowance: C3 = 1.0 mm

Total allowance:

C′ = C1 + C3 = 1.18 mm

Design shell thickness:

S1 = S0 + C′ = 1.8 + 1.18 ≈ 3.0 mm

Therefore we select a 3 mm stainless steel shell for the housing.

3.3 Elliptical head thickness

For a standard elliptical head, a common thin-wall expression is:

S′0 = (PC · Di) / (2 · [σ] · φ − 0.5 · PC)

Using the same parameters:

S′0 ≈ 1.8 mm

Allowances for the head:

- Plate negative tolerance: C1 = 0.18 mm

- Forming thinning allowance: C2 = 0.1 × S′0 ≈ 0.18 mm

- Corrosion allowance: C3 = 1.0 mm

Total head allowance:

C″ = C1 + C2 + C3 ≈ 1.36 mm

Design head thickness:

S2 = S′0 + C″ = 1.8 + 1.36 ≈ 3.16 mm

We therefore specify a 3.5 mm stainless steel plate for the formed elliptical head, which gives extra margin for forming tolerances and fabrication practice.

Step 4 — Nozzle Sizing and Piping Connections

Nozzle size is chosen to keep velocity within an acceptable range and to match the upstream/downstream piping. For security filter sizing, a liquid velocity of approximately 1.0–1.5 m/s is comfortable.

4.1 Sizing rule for nozzle diameter

A convenient engineering formula for water is:

d = 18.8 · √(Q / u)

- d — nozzle diameter (mm)

- Q — volumetric flow (m³/h)

- u — design velocity (m/s)

Using Q = 174 m³/h and u = 1.5 m/s:

d = 18.8 · √(174 / 1.5) ≈ 18.8 · √116 ≈ 18.8 · 10.77 ≈ 202 mm

So we select DN200 nozzles for both inlet and outlet.

4.2 Other nozzle and connection details

- Use flanges rated for at least the design pressure (e.g. PN16 or Class 150 for this example).

- Provide a top vent nozzle (small bore, e.g. DN25) for air removal and a bottom drain nozzle (DN25–DN40) for complete draining.

- Install thermowells and pressure tapping points close to the housing to facilitate operation and troubleshooting.

Step 5 — Layout, Centreline Elevation and Maintenance Space

Mechanical sizing is not complete until installation and maintenance constraints are considered.

5.1 Example geometry

- Internal diameter: 450 mm

- Overall shell length between heads: approximately 1500 mm

- Centreline elevation: 915 mm above finished floor

- Horizontal orientation with saddle supports and anchor bolts

5.2 Maintenance and ergonomics

- Provide clear axial space in front of the head equal to at least the cartridge length plus handling allowance (e.g. ≥1.5 times cartridge length).

- Ensure sufficient height for an operator to pull cartridges while standing on the floor or a safe platform.

- Consider hoisting or lifting points for head removal if the head is heavy.

- Provide enough piping flexibility (expansion joints or loops) so that head removal does not overstress the nozzles.

Design Checklist and Common Pitfalls

Hydraulic design pitfalls

- Per-cartridge flow too high → short run length and high ΔP.

- No clear ΔP change-out criterion or no DP measurement at all.

- Ignoring the impact of water temperature and viscosity on ΔP.

Mechanical design pitfalls

- Wall thickness estimated by “experience” without calculations.

- Corrosion allowance omitted, especially for aggressive or chlorinated waters.

- Head thinning during forming not accounted for.

- Nozzles undersized, causing high velocity, noise and erosion.

Operational and safety pitfalls

- No vent or drain, making filling, draining and sanitization difficult.

- Cartridge change-out space too tight, leading to unsafe lifting practices.

- No isolation valves, making maintenance impossible without stopping the entire plant.

One-Page Workflow — Security Filter Sizing for RO

- Define design basis: flow Q, pressure, temperature, water quality, cartridge type and allowed ΔP.

- Calculate cartridge count: choose q, compute m = Q / q, and round up.

- Select housing diameter and layout: choose Di, orientation (horizontal/vertical) and head type.

- Set ΔP control strategy: define clean ΔP, alarm and change-out limits; specify instrumentation.

- Compute wall thickness: determine design pressure, allowable stress, joint efficiency; calculate shell and head thickness with allowances.

- Size nozzles: select inlet/outlet, vent and drain sizes based on velocity and piping standards.

- Check layout: verify centreline elevation, maintenance space, supports and accessibility.

FAQ — Quick Answers for Buyers and Engineers

How do I pick the design flow per cartridge?

Use the cartridge manufacturer’s recommended clean-water flow range as the starting point. For security filter sizing in RO pretreatment, it is safer to operate in the lower half of the range to achieve longer run time and lower ΔP. Multiply the chosen flow per cartridge by the number of cartridges to verify that the total meets the design flow.

What differential pressure should I use as the change-out limit?

Even if the cartridge can tolerate 1.0 MPa or more, typical RO plants use a change-out limit of 0.08–0.10 MPa. This keeps the high-pressure pump stable and prevents excessive compaction or bypassing of the cartridges.

When should I choose a horizontal vs. vertical security filter?

Horizontal housings are easier for frequent cartridge change-out and are preferred when there is enough floor space. Vertical housings save footprint and may be convenient for smaller flows or where space is constrained, but they need sufficient overhead clearance and safe platforms.

Can I reuse the same housing if RO capacity is upgraded later?

Sometimes. Check whether the existing housing has enough cartridge positions and nozzle capacity for the higher flow, and verify that shell and head thickness meet the new design pressure. If in doubt, consult the original vessel calculations or perform a rerate assessment.

How do I confirm whether the wall thickness is adequate?

Compare the actual shell and head thickness with the calculated minimum thickness from the applicable pressure vessel code, including all allowances. If you do not have the original calculations, you can back-calculate using the method shown in this guide, then add safety margin and verify with a qualified mechanical engineer.

Further Reading & Related Tools

- Industrial Water Treatment Solutions

- RO and UF Case Studies

- Stark Water Tools — Online Calculators

- More RO Design and Pretreatment Guides

- Cartridge filter — basic principles

- ASME BPVC Section VIII Division 1 — pressure vessel rules

Next Steps

If you are planning a new RO project or upgrading an existing plant and want a defensible security filter sizing package (including drawings and calculations), we can help. Share your design flow, pressure and pretreatment layout, and we will translate it into a complete security filter specification.

Request a Quote to start your security filter and RO pretreatment review.