Stark Industrial 6″ Flange Pressure Vessel Series (Heavy Duty)

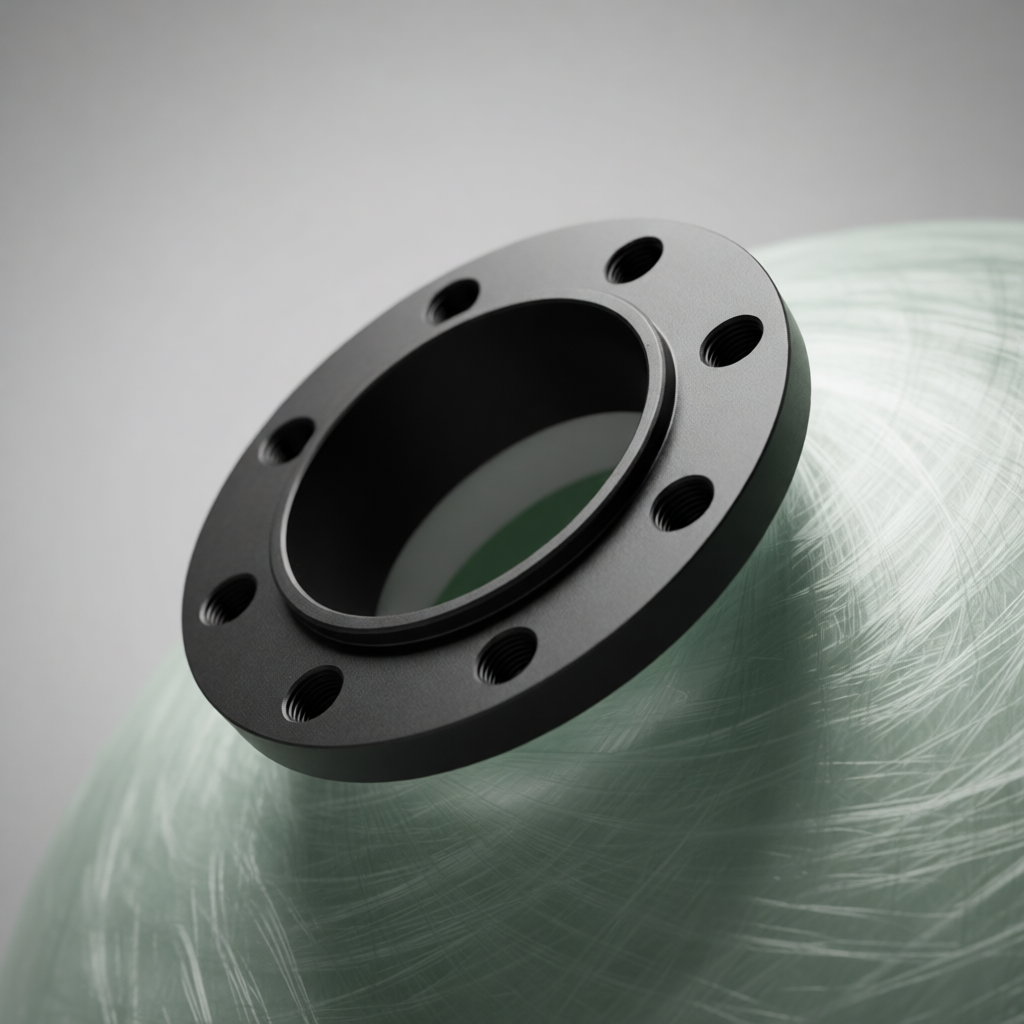

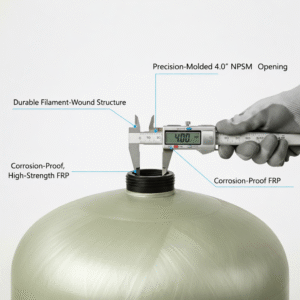

The Stark industrial **6″ Flange pressure vessel** is engineered for high-volume filtration applications. Featuring a secure 6-inch flange top opening, this heavy-duty tank series (36″-72″ diameter) is designed for municipal water treatment and large-scale industrial plants requiring maximum flow rates and absolutely leak-proof pipe connections.

Description du produit

Engineered for the Toughest Industrial Demands.

The Stark **6″ Flange pressure vessel** series represents the pinnacle of large-scale composite manufacturing. Unlike threaded connections which can be prone to leaks under the stress of large piping systems, our 6-inch flange interface offers a robust, bolted connection point compatible with standard DN150 industrial piping. This ensures zero-leakage performance even under high vibration or pressure surges common in desalination plants and municipal facilities.

Our proprietary multi-axis winding process ensures that even our largest 72-inch vessels maintain structural rigidity and uniform pressure distribution, offering a superior, corrosion-resistant alternative to rubber-lined steel tanks.

Installation & Standard Data:

Proper flange alignment and bolt torque are critical for large vessel safety. For detailed flange dimension drawings (ANSI/DIN), bolt circle specifications, and installation torque guides, please reference the technical documentation at our specialized manufacturing division:

Stark Tank Manufacturing – 6″ Flange Series Technical Specs

.

Paramètres du produit

Below are the verified specifications for our 6″ Flange top-mount series. These heavy-duty tanks are designed for industrial applications requiring high flow rates.

| Modèle | Volume Capacité | Dimensions (Dia x H) | Flow Rate (m³/h) | B2B Quote | ||

|---|---|---|---|---|---|---|

| Type | US Gal | Liters | Nominal | mm | (Filter/Softener) | Action |

| STK-3694 | 318.4 | 1205 | 36″ x 94″ | Ø900 x 2465 | 7.6-10 / 12-19 | Inquiry |

| STK-4094 | 351.9 | 1332 | 40″ x 94″ | Ø1000 x 2430 | 9.4-11.7 / 15.7-23.5 | Inquiry |

| STK-4272 | 290.6 | 1100 | 42″ x 72″ | Ø1080 x 1850 | 15-25 / 26-30 | Inquiry |

| STK-4872 | 345.6 | 1308 | 48″ x 72″ | Ø1200 x 1880 | 13.5-17 / 22.6-34 | Inquiry |

| STK-4894 | 504.4 | 1909 | 48″ x 94″ | Ø1200 x 2430 | 13.5-17 / 22.6-34 | Inquiry |

| STK-6083 | 570.1 | 2158 | 60″ x 83″ | Ø1500 x 2120 | 21-27 / 35-53 | Inquiry |

| STK-6094 | 710.2 | 2688 | 60″ x 94″ | Ø1500 x 2430 | 21-27 / 35-53 | Inquiry |

| STK-6383 | 681.6 | 2580 | 63″ x 83″ | Ø1600 x 2100 | 25-45 / 46-56 | Inquiry |

| STK-7294 | 940.8 | 3561 | 72″ x 94″ | Ø1800 x 2400 | 30-40 / 50-76 | Inquiry |

*Note: US dimensions are nominal. Flow rates are for reference only. Please consult our engineers for precise system design.

Industrie concernée

- Municipal Water Treatment:

Large-scale sand and carbon filtration for city water supplies, removing sediment and contaminants at high throughput. - Seawater Desalination:

Pre-treatment filtration for SWRO plants, utilizing corrosion-resistant FRP to withstand aggressive saline environments. - Power Plant Cooling Systems:

Side-stream filtration for cooling towers to reduce suspended solids and prevent heat exchanger fouling.

Avantage 1

Secure Flange Connection

For vessels exceeding 36 inches in diameter, threaded connections are often insufficient. Stark’s 6-inch flange top opening provides a standardized, bolted connection that eliminates the risk of thread stripping or cross-threading during installation.This design allows for the secure attachment of heavy industrial piping (steel or large diameter UPVC) and ensures a reliable seal capable of withstanding system vibration and hydraulic shock.Avantage DEUX

Massive Capacity, Minimal Maintenance

With diameters up to 72 inches, these vessels hold thousands of liters of media, allowing for extended service runs between backwashes. Unlike traditional rubber-lined steel tanks, Stark FRP vessels are inherently rust-proof and require zero painting or lining maintenance.This significantly reduces the total cost of ownership (TCO) for large-scale projects while providing a service life that often exceeds 10 years in harsh conditions.Produits apparentés

Produits similaires

FAQ

Q1 : Quelle est la durée de vie du système d'osmose inverse ?

La durée de vie d'un système d'osmose inverse dépend de la qualité de l'eau et de l'entretien. En règle générale, la membrane dure 2 à 3 ans, tandis que le système lui-même peut durer plus de 10 ans s'il est bien entretenu.

Q2 : Le système peut-il être personnalisé en fonction des différentes conditions de l'eau ?

Oui, tous nos systèmes sont entièrement personnalisables. Nous analysons vos besoins en matière de rapports sur l'eau et d'applications avant de vous proposer des solutions sur mesure.

Q3 : Quelles sont les normes auxquelles répondent les équipements STARK ?

Nos produits sont conformes aux normes CE et ISO 9001 et peuvent être conçus pour répondre à des réglementations régionales spécifiques ou à des normes industrielles sur demande.

Q4 : Quel est le délai de livraison des systèmes STARK RO ?

Les systèmes standard sont expédiés dans un délai de 7 à 15 jours. Pour les commandes personnalisées, le délai peut aller jusqu'à 20-25 jours en fonction de la complexité.

Q5 : Fournissez-vous une assistance technique ou des conseils d'installation ?

Oui. Nous fournissons une documentation technique complète, des conseils à distance par vidéo et nous pouvons envoyer des ingénieurs à l'étranger sur demande.

Q6 : Qu'est-ce qui est inclus dans votre devis ?

Notre devis comprend le système RO complet, le panneau de contrôle, les pompes, les unités de prétraitement et tous les accessoires nécessaires. Les outils d'installation et les pièces de rechange peuvent être inclus sur demande.